The core advantage of using a Vacuum Hot Press (VHP) furnace for Zinc Sulfide (ZnS) ceramics lies in its ability to decouple densification from grain growth. By applying simultaneous mechanical pressure (up to 20 MPa) and high vacuum ($10^{-3}$ mtorr) at approximately 1020°C, VHP forces the material to reach near-theoretical density at significantly lower temperatures than pressureless sintering, effectively eliminating the micro-pores that destroy infrared transparency.

Core Takeaway Achieving optical transparency in ceramics requires a pore-free microstructure, but high temperatures usually cause grains to grow, reducing strength. VHP solves this by using mechanical force—not just heat—to drive densification. This allows for the production of ZnS with superior infrared transmission and mechanical strength without the extreme thermal loads required by pressureless methods.

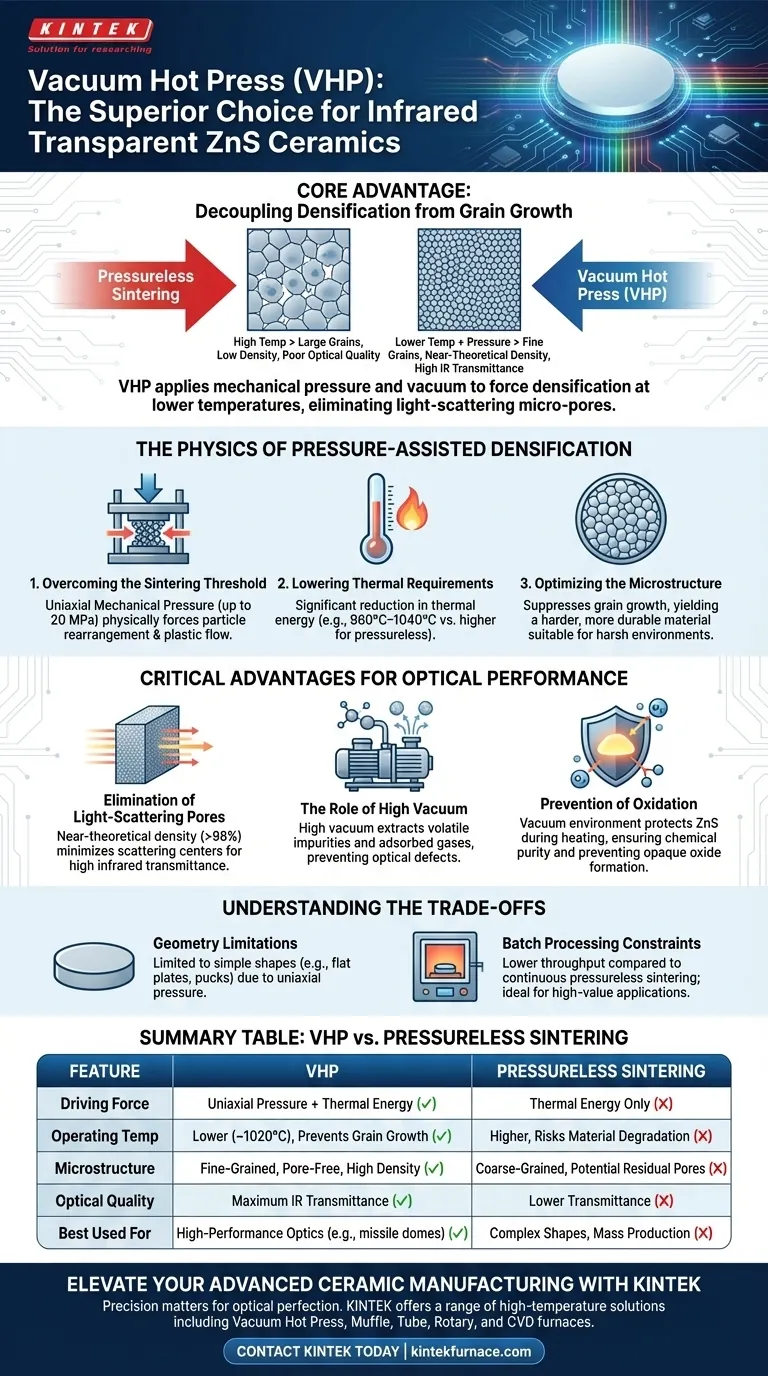

The Physics of Pressure-Assisted Densification

Overcoming the Sintering Threshold

In pressureless sintering, densification relies entirely on thermal energy to diffuse atoms and close gaps between particles. This requires extremely high temperatures. VHP introduces an external driving force: uniaxial mechanical pressure (typically around 15–20 MPa). This pressure physically forces particles to rearrange and undergo plastic flow, mechanically closing the voids between them.

Lowering Thermal Requirements

Because mechanical pressure assists the process, the thermal energy required is significantly reduced. VHP allows ZnS to sinter effectively at moderate temperatures (e.g., 960°C–1040°C). Pressureless sintering would require higher temperatures to achieve similar density, which often leads to material degradation or uncontrolled microstructural changes.

Optimizing the Microstructure

The combination of lower temperatures and mechanical pressure results in a fine-grained microstructure. By avoiding the excessive heat of pressureless sintering, VHP suppresses grain growth. This is critical because large grains can reduce the mechanical strength of the ceramic. VHP yields a harder, more durable material suitable for harsh environments, such as missile domes.

Critical Advantages for Optical Performance

Elimination of Light-Scattering Pores

For a ceramic to be transparent in the infrared spectrum, it must be virtually free of porosity. Even microscopic pores act as scattering centers, blocking light transmission. The VHP exerts a densification force that squeezes out residual pores that pressureless sintering often leaves behind. This results in a material density that is near-theoretical (e.g., >98%), directly translating to high infrared transmittance.

The Role of High Vacuum

Temperature and pressure are supported by a high vacuum environment ($10^{-3}$ mtorr or better). This vacuum is essential for extracting volatile impurities and adsorbed gases trapped within the powder interstices. Without the vacuum, these gases would be trapped inside the closing pores, preventing full densification and causing optical defects.

Prevention of Oxidation

ZnS is sensitive to oxidation at high temperatures, which creates opaque oxides that ruin transparency. The vacuum environment protects the material during the heating cycle, ensuring the chemical purity of the Zinc Sulfide is maintained throughout the densification process.

Understanding the Trade-offs

Geometry Limitations

While VHP offers superior material properties, it applies pressure uniaxially (from top and bottom). This generally limits part geometries to simple shapes like flat plates, discs, or pucks. Complex, near-net-shape components are difficult to manufacture directly with VHP compared to pressureless sintering or other methods like Hot Isostatic Pressing (HIP).

Batch Processing Constraints

VHP is inherently a batch process. The equipment must be loaded, evacuated, heated, pressed, cooled, and unloaded for every cycle. This generally results in lower throughput compared to continuous pressureless sintering furnaces, making VHP better suited for high-value, high-performance applications rather than mass commodity production.

Making the Right Choice for Your Goal

To determine if VHP is the correct manufacturing route for your specific ZnS application, consider your performance priorities:

- If your primary focus is Optical Transmittance: VHP is superior because the combination of vacuum and pressure creates the pore-free, high-density structure required to minimize infrared light scattering.

- If your primary focus is Mechanical Durability: VHP is the optimal choice as it achieves full density while suppressing grain growth, yielding harder and stronger ceramics than pressureless methods.

- If your primary focus is Complex Geometry: You may need to consider that VHP produces simple shapes that require post-process machining, unlike pressureless sintering which can accommodate more complex green body shapes.

Summary: VHP effectively replaces thermal energy with mechanical energy, allowing you to manufacture ZnS ceramics that are optically clear and mechanically robust without the grain-coarsening effects of high-temperature pressureless sintering.

Summary Table:

| Feature | Vacuum Hot Press (VHP) | Pressureless Sintering |

|---|---|---|

| Driving Force | Uniaxial Pressure + Thermal Energy | Thermal Energy Only |

| Operating Temp | Lower (~1020°C); prevents grain growth | Higher; risks material degradation |

| Microstructure | Fine-grained, pore-free, high density | Coarse-grained, potential residual pores |

| Optical Quality | Maximum IR transmittance | Lower transmittance due to scattering |

| Best Used For | High-performance optics (e.g., missile domes) | Complex shapes, mass production |

Elevate Your Advanced Ceramic Manufacturing with KINTEK

Precision matters when your goal is optical perfection. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-temperature solutions, including Vacuum Hot Press systems, Muffle, Tube, Rotary, and CVD furnaces.

Whether you are scaling production for infrared optics or developing next-generation materials, our customizable systems ensure you achieve the exact density and microstructure your application demands.

Ready to optimize your sintering process? Contact KINTEK today to discuss your unique needs with our technical specialists.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What are the benefits of using a vacuum hot press sintering furnace for the preparation of SiCw/2024 aluminum matrix composites? Achieve High-Performance Aerospace Materials

- Why are high-strength graphite molds preferred for the vacuum hot pressing sintering of Al-Si/graphite composites?

- What role does SPS equipment play in half-Heusler fabrication? Mastering Density and Microstructure for Thermoelectrics

- What are the advantages of using a vacuum hot press sintering furnace for preparing high-density carbon nanotube reinforced copper matrix composites? Achieve Maximum Density and Purity for Superior Performance

- What are the primary functions of high-strength graphite molds? Optimize GNPs-Cu/Ti6Al4V Hot-Pressing Sintering

- What are the temperature-based classifications for vacuum hot pressing sintering furnaces? Choose the Right Furnace for Your Materials

- Why are pressure and temperature control crucial for Cu-CNT composites? Eliminate Delamination in Vacuum Hot Pressing

- What functions do graphite molds perform during vacuum hot press sintering? Discover their active role in densification