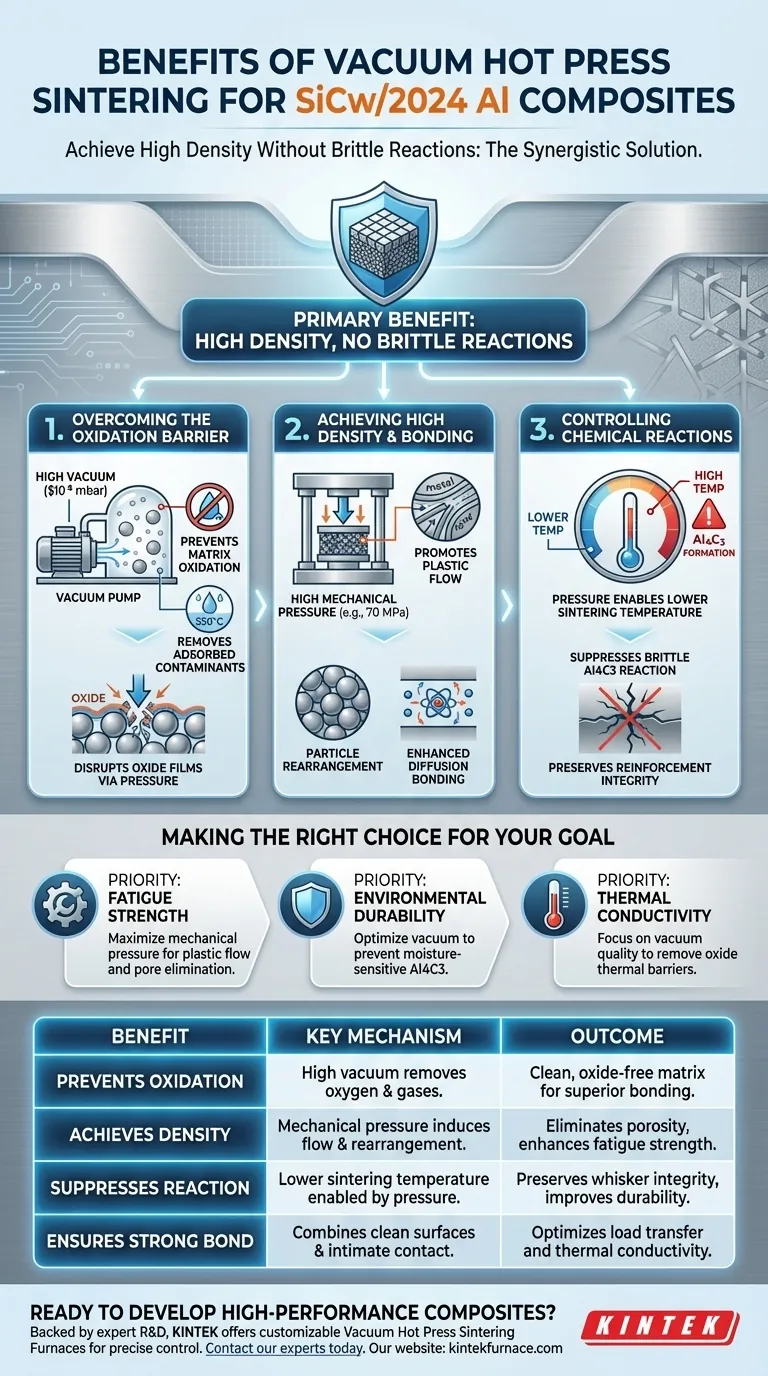

The primary benefit of using a vacuum hot press sintering furnace for SiCw/2024 aluminum composites is the ability to achieve high material density without triggering the formation of brittle reaction products. By integrating high vacuum, mechanical pressure, and precise heating, this process effectively eliminates porosity and disrupts stubborn oxide films, ensuring a strong metallurgical bond between the silicon carbide whiskers and the aluminum matrix.

Vacuum hot pressing solves the fundamental conflict in sintering aluminum composites: the need for high heat to bond materials versus the risk of degrading the material through oxidation or chemical reaction. It leverages mechanical pressure to force densification at lower temperatures, preserving the integrity of the reinforcement phase.

Overcoming the Oxidation Barrier

Prevention of Matrix Oxidation

Aluminum alloys, such as 2024, are highly reactive and prone to rapid oxidation at elevated temperatures. A high vacuum environment (e.g., $10^{-5}$ mbar) removes oxygen from the chamber, preventing the formation of new oxide layers on the aluminum powder during the heating phase.

Removal of Adsorbed Contaminants

Aluminum powder surfaces naturally adsorb water vapor and other gases. The vacuum system effectively promotes the desorption and exhaust of chemically adsorbed water, particularly as temperatures approach 550°C. Removing these contaminants prevents the formation of internal gas pores that would otherwise compromise the composite's structural integrity.

Disruption of Oxide Films

While the vacuum prevents new oxidation, the mechanical pressure plays a role in managing existing oxide films. The application of continuous axial pressure forcibly disrupts the oxide film on particle surfaces. This breakage is essential to allow direct contact between the metal matrix and the SiC reinforcement.

Achieving High Density and Bonding

Promoting Plastic Flow

The application of high mechanical pressure (e.g., 70 MPa) induces plastic flow in the aluminum matrix. This physically forces the metal to flow around the rigid SiC whiskers and fill the voids between particles.

Particle Rearrangement

Pressure drives particle rearrangement, ensuring that the components are packed as tightly as possible. This mechanism is the primary driver for eliminating internal pores and achieving near-theoretical density.

Enhanced Diffusion Bonding

The combination of a clean, oxide-free surface (via vacuum) and intimate contact (via pressure) significantly improves atomic diffusion efficiency. This results in a robust metallurgical bond between the 2024 aluminum matrix and the SiCw reinforcement, which is critical for load transfer and thermal conductivity.

Controlling Chemical Reactions (The Critical Trade-off)

Understanding the Temperature Sensitivity

A major challenge in Al-SiC composites is the formation of Aluminum Carbide ($Al_4C_3$). This is a brittle, water-soluble interfacial reactant that severely degrades the mechanical properties of the composite. It typically forms when the processing temperature is too high or exposure times are too long.

Densification at Lower Temperatures

The "synergistic" benefit of vacuum hot pressing is that mechanical pressure reduces the thermal energy required for densification.

Because pressure drives the consolidation, sintering can occur at lower temperatures (solid-state sintering). This suppresses the chemical reaction between Aluminum and Silicon Carbide, effectively inhibiting the formation of harmful $Al_4C_3$ while still achieving a fully dense material.

Making the Right Choice for Your Goal

To maximize the performance of your SiCw/2024 composites, align your processing parameters with your specific engineering targets.

- If your primary focus is Fatigue Strength: Prioritize high mechanical pressure to maximize plastic flow and eliminate microscopic pores that could act as crack initiation sites.

- If your primary focus is Environmental Durability: Ensure your vacuum levels are optimized to prevent $Al_4C_3$ formation, as this reactant degrades rapidly when exposed to moisture.

- If your primary focus is Thermal Conductivity: Focus on the vacuum quality to fully remove oxide films, as these interfaces act as thermal barriers and hinder heat transfer.

By strictly controlling the vacuum and pressure variables, you transform a potentially brittle mixture into a high-performance aerospace-grade composite.

Summary Table:

| Benefit | Key Mechanism | Outcome for SiCw/2024 Composite |

|---|---|---|

| Prevents Oxidation & Contamination | High vacuum environment removes oxygen and adsorbed gases. | Clean, oxide-free matrix for superior bonding. |

| Achieves Near-Theoretical Density | Mechanical pressure induces plastic flow and particle rearrangement. | Eliminates porosity, enhances fatigue strength. |

| Suppresses Brittle Reaction (Al4C3) | Lower sintering temperature enabled by pressure. | Preserves whisker integrity, improves durability. |

| Ensures Strong Metallurgical Bond | Combines clean surfaces and intimate contact from pressure. | Optimizes load transfer and thermal conductivity. |

Ready to develop high-performance SiCw/aluminum composites for your aerospace or advanced materials application?

Backed by expert R&D and manufacturing, KINTEK offers a range of customizable Vacuum Hot Press Sintering Furnaces. Our systems are engineered to deliver the precise control over vacuum, pressure, and temperature you need to achieve superior material properties without compromising your reinforcement phase.

Contact our experts today to discuss how we can customize a furnace solution for your unique research and production goals.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What are the primary application fields for box furnaces and vacuum furnaces? Choose the Right Furnace for Your Process

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing