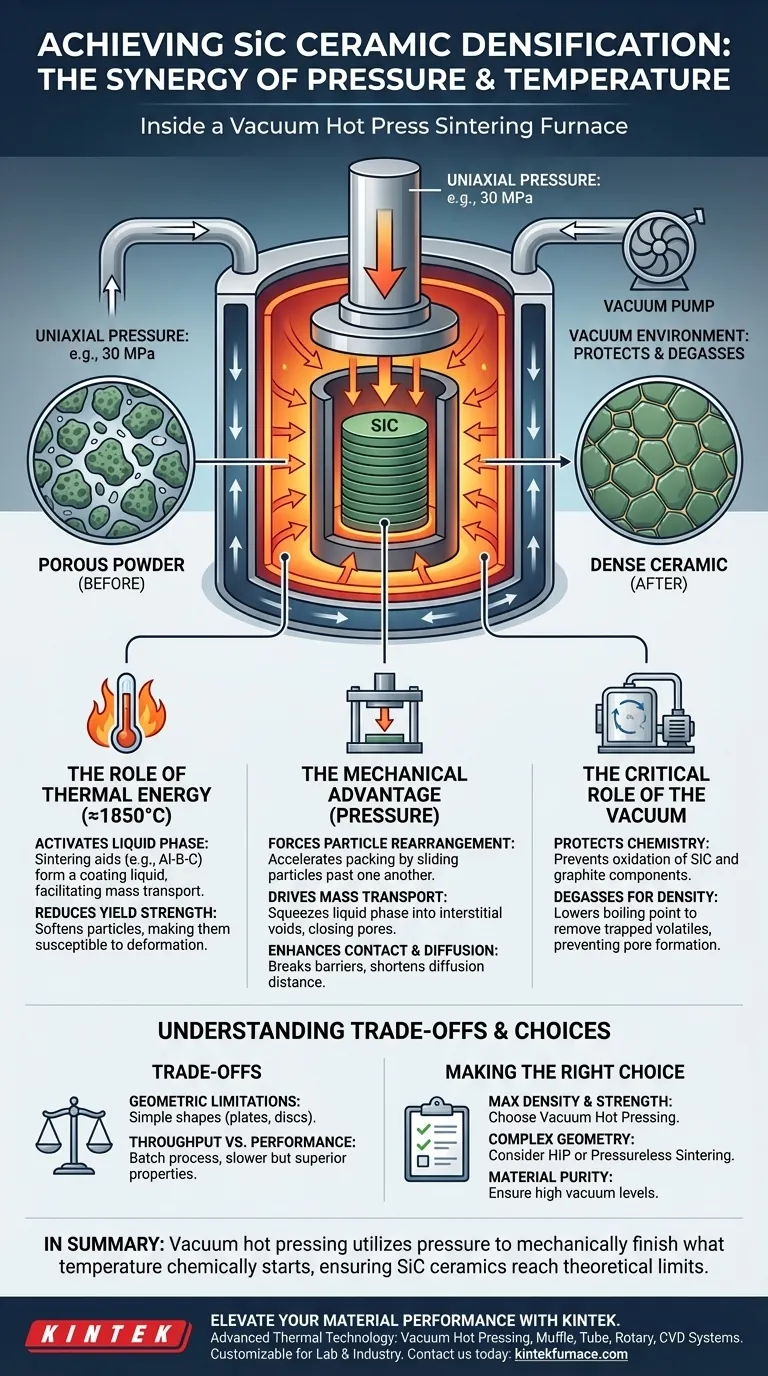

The vacuum hot press sintering furnace achieves densification by coupling thermal activation with mechanical force to overcome the natural resistance of Silicon Carbide (SiC). The process utilizes a high-temperature environment (typically 1850°C) to create a liquid phase via sintering aids, while simultaneously applying uniaxial pressure (e.g., 30 MPa) to physically force particle rearrangement and eliminate voids.

Core Insight: The "synergy" is thermodynamic: external pressure acts as an additional sintering driving force. This allows SiC to achieve near-theoretical density at temperatures significantly lower than those required for pressureless sintering, preserving fine grain structure and mechanical strength.

The Role of Thermal Energy

Activating Liquid Phase Sintering

At temperatures around 1850°C, the furnace activates specific sintering aids, such as Al-B-C compounds.

These additives react to form a liquid phase that coats the solid SiC particles. This liquid is the medium through which mass transport occurs, essential for binding the ceramic matrix.

Reducing Yield Strength

The extreme heat softens the material components.

This reduction in yield strength makes the particles more susceptible to the mechanical forces applied later in the process. It prepares the microstructure for deformation without fracturing.

The Mechanical Advantage (Pressure)

Forcing Particle Rearrangement

While heat softens the material, the applied axial pressure (e.g., 30 MPa) provides the kinetic energy needed for movement.

Pressure forces the rigid SiC particles to slide past one another and pack tightly. This accelerates particle rearrangement, a process that would be incredibly slow or incomplete under thermal energy alone.

Driving Mass Transport

The external pressure actively squeezes the liquid phase formed by the aids into the interstitial voids between particles.

This mechanism acts like a hydraulic pump at the microscopic level. It fills the gaps that naturally occur between irregular particles, drastically reducing porosity.

Enhancing Contact and Diffusion

Pressure physically breaks down diffusion barriers.

By forcing intimate contact between particles, the process shortens the diffusion distance for atoms. This facilitates rapid bonding and densification, effectively "closing" the material structure.

The Critical Role of the Vacuum

Protecting the Chemistry

The vacuum environment is not passive; it is a chemical shield.

It prevents the oxidation of SiC particles (which would form a silica impurity layer) and protects the graphite mold components from burning up at high temperatures.

Degassing for Density

Vacuum conditions lower the boiling point of trapped volatiles.

This allows gases trapped within the powder compact or dissolved in the lattice to escape easily. Removing these gases prevents the formation of pressurized pores that would otherwise inhibit densification.

Understanding the Trade-offs

Geometric Limitations

Hot pressing applies pressure uniaxially (from one direction).

This limits the process to relatively simple shapes, such as plates, discs, or cylinders. Complex geometries with undercuts or internal channels are generally not feasible with this method.

Throughput vs. Performance

This is typically a batch process, not a continuous one.

While it produces superior material properties, the cycle times are longer and the output volume is lower compared to pressureless sintering. You are trading manufacturing speed for material performance.

Making the Right Choice for Your Goal

To decide if this technology aligns with your project requirements, consider the following:

- If your primary focus is maximum density and mechanical strength: Rely on vacuum hot pressing, as the pressure-assisted densification eliminates virtually all porosity and flaws.

- If your primary focus is complex component geometry: Consider Hot Isostatic Pressing (HIP) or pressureless sintering, as uniaxial hot pressing is limited to simple shapes.

- If your primary focus is material purity: Ensure the vacuum system is capable of high-vacuum levels to prevent the formation of oxide layers that degrade interface bonding.

In summary, vacuum hot pressing utilizes pressure to mechanically finish what temperature chemically starts, ensuring SiC ceramics reach their theoretical limits of density and strength.

Summary Table:

| Parameter | Role in Densification | Key Benefit |

|---|---|---|

| High Temperature | Activates liquid phase sintering & softens particles | Facilitates mass transport and deformation |

| Uniaxial Pressure | Forces particle rearrangement & fills interstitial voids | Achieves near-theoretical density at lower temps |

| Vacuum Environment | Prevents oxidation & removes trapped gases | Ensures material purity and prevents pore formation |

| Sintering Aids | Creates a coating liquid phase | Lowers the required activation energy for bonding |

Elevate Your Material Performance with KINTEK

Unlock the full potential of SiC ceramics with KINTEK’s advanced thermal technology. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Vacuum Hot Pressing, Muffle, Tube, Rotary, and CVD systems, all customizable to meet your unique laboratory or industrial needs. Whether you require maximum mechanical strength or specialized material purity, our high-temperature furnaces provide the precision control necessary for superior results.

Ready to optimize your sintering process? Contact our technical experts today to discuss your project requirements and discover the KINTEK advantage.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the mechanism of hot press? Achieve Full Densification for Advanced Materials

- What is the effect of extended holding time during Vacuum Hot Pressing (VHP)? Enhance Al3Ti Phase Purity and Density

- What is hot pressing and what does it involve? Unlock Superior Material Density and Strength

- Why must the surface layer of titanium alloy samples be removed by grinding? Ensure High Strength After Vacuum Hot Press

- What medical applications benefit from Vacuum Hot Press technology? Enhance Biocompatible Implants and Tools

- What are the technical advantages of using a Spark Plasma Sintering (SPS) system for Barium Titanate ceramics?

- Why is vacuum hot press sintering recommended over pressureless sintering? Achieve Peak Density for IZO Ceramic Targets

- What are the temperature-based classifications for vacuum hot pressing sintering furnaces? Choose the Right Furnace for Your Materials