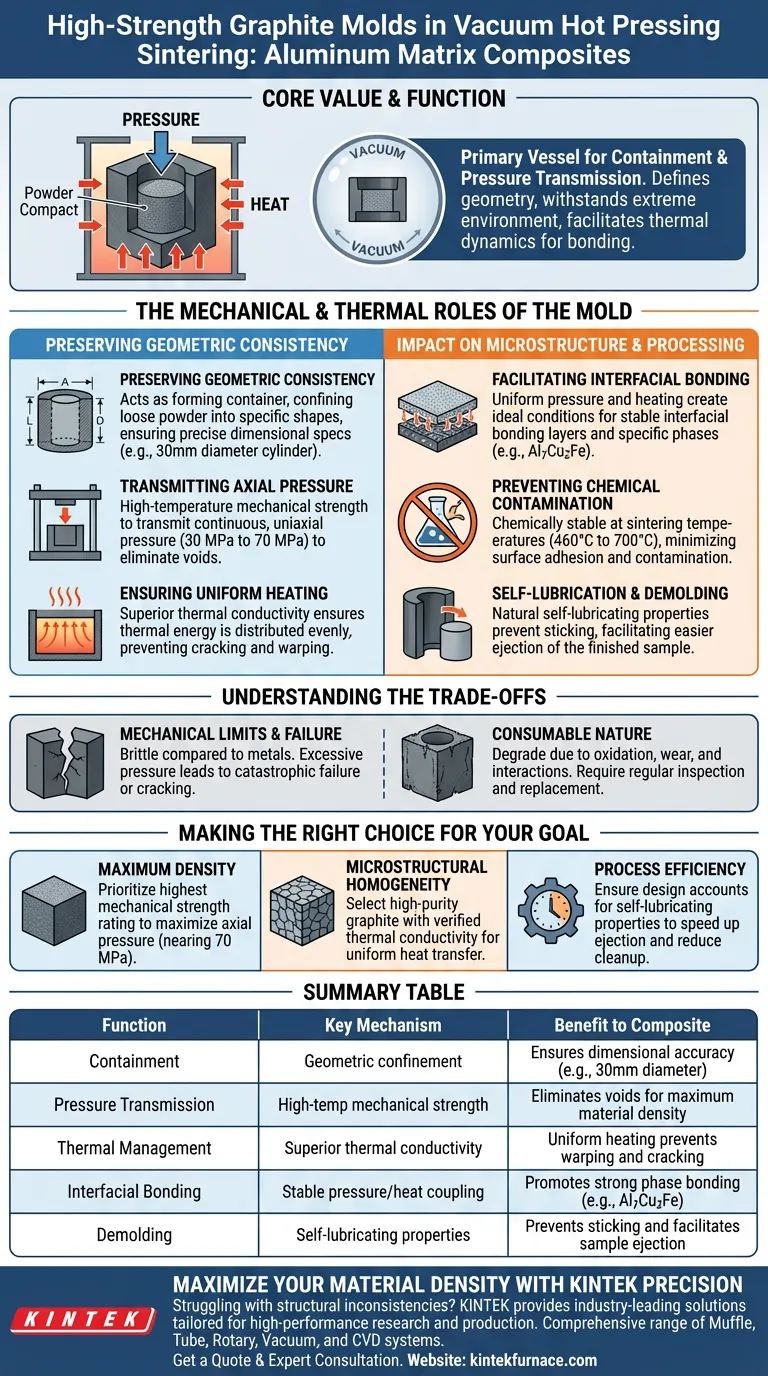

High-strength graphite molds function as the primary vessel for containment and pressure transmission during the vacuum hot pressing sintering of aluminum matrix composites. They are responsible for defining the sample's precise geometry (such as maintaining a consistent diameter) while withstanding the extreme environment of the sintering furnace. Simultaneously, they facilitate the thermal dynamics required to bond the composite powder into a solid, high-density material.

The core value of the graphite mold lies in its ability to couple high mechanical strength with excellent thermal conductivity. It enables the simultaneous application of heat and pressure—transforming loose powder into a dense composite with stable interfacial bonding—without chemically degrading the aluminum matrix.

The Mechanical and Thermal Roles of the Mold

Preserving Geometric Consistency

The most immediate function of the graphite mold is to act as a forming container. It confines the loose composite powder into a specific shape, ensuring the final sintered product meets precise dimensional specifications, such as a consistent 30 mm diameter cylinder.

Transmitting Axial Pressure

Vacuum hot pressing relies on compressing powder to achieve densification. The graphite mold must possess high-temperature mechanical strength to transmit continuous, uniaxial pressure to the powder body.

This pressure, often ranging from 30 MPa to 70 MPa depending on the specific process, forces the powder particles together to eliminate voids.

Ensuring Uniform Heating

Graphite is selected for its superior thermal conductivity. In a vacuum environment, where heat transfer can be challenging, the mold ensures that thermal energy is distributed evenly across the entire composite sample.

Uniform heating is critical. It prevents temperature gradients that could lead to cracking, warping, or uneven sintering rates within the aluminum matrix.

Impact on Microstructure and Processing

Facilitating Interfacial Bonding

The combination of uniform pressure and even heating creates the ideal conditions for microstructural evolution. The mold's stability allows for the formation of stable interfacial bonding layers between the matrix and reinforcements.

For example, this stable environment is conducive to forming specific phases, such as the Al7Cu2Fe phase, which is essential for the mechanical integrity of certain aluminum composites.

Preventing Chemical Contamination

Aluminum is highly reactive, yet high-strength graphite remains relatively chemically stable at sintering temperatures (e.g., 460°C to 700°C). The mold does not adhere severely to the aluminum matrix, minimizing surface contamination.

Self-Lubrication and Demolding

Graphite possesses natural self-lubricating properties. This characteristic is vital during the post-sintering phase, as it prevents the metal composite from sticking to the mold walls, facilitating easier ejection (demolding) of the finished sample.

Understanding the Trade-offs

Mechanical Limits and Failure

While graphite has excellent high-temperature strength, it is brittle compared to metals. If the applied pressure exceeds the mold's material limit (tensile or compressive strength), catastrophic failure or cracking of the mold can occur, ruining the sample.

Consumable Nature

Graphite molds are technically consumables. Over repeated cycles, they degrade due to oxidation (if vacuum is breached), mechanical wear from pressure application, or slight chemical interactions at the interface. They require regular inspection and replacement to maintain dimensional accuracy.

Making the Right Choice for Your Goal

If your primary focus is Maximum Density:

- Prioritize molds with the highest possible mechanical strength rating to safely maximize the axial pressure (e.g., nearing 70 MPa) applied to the powder.

If your primary focus is Microstructural Homogeneity:

- Select high-purity graphite with verified thermal conductivity specs to ensure the heat transfer is perfectly uniform, promoting even phase precipitation (like Al7Cu2Fe).

If your primary focus is Process Efficiency:

- Ensure the mold design accounts for graphite's self-lubricating properties to speed up the ejection cycle and reduce post-processing cleanup.

The graphite mold is not just a container; it is an active thermal-mechanical component that dictates the final quality of your composite.

Summary Table:

| Function | Key Mechanism | Benefit to Composite |

|---|---|---|

| Containment | Geometric confinement | Ensures dimensional accuracy (e.g., 30mm diameter) |

| Pressure Transmission | High-temp mechanical strength | Eliminates voids for maximum material density |

| Thermal Management | Superior thermal conductivity | Uniform heating prevents warping and cracking |

| Interfacial Bonding | Stable pressure/heat coupling | Promotes strong phase bonding (e.g., Al7Cu2Fe) |

| Demolding | Self-lubricating properties | Prevents sticking and facilitates sample ejection |

Maximize Your Material Density with KINTEK Precision

Are you struggling with structural inconsistencies or mold failure in your sintering process? KINTEK provides industry-leading solutions tailored for high-performance research and production.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique composite requirements. Whether you need to optimize axial pressure or ensure perfect microstructural homogeneity, our equipment delivers the control you need.

Contact us today to find the perfect furnace solution for your aluminum matrix composites!

Get a Quote & Expert Consultation

Visual Guide

References

- Juan Wang, Zhong Yang. Microstructure and Properties of Al-Cu-Fe-Ce Quasicrystalline-Reinforced 6061 Aluminum Matrix Composites after Aging. DOI: 10.3390/coatings14030372

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the advantages of using hot pressing in manufacturing? Achieve Superior Quality and Precision

- What is a vacuum press and what are its primary uses? Unlock High-Performance Material Processing

- Why is a high-vacuum environment required during SPS for transparent materials? Achieve Optical Purity

- What control features does a vacuum hot press furnace offer? Precision Control for Advanced Materials Processing

- How does vacuum hot pressing improve material properties? Achieve Denser, Stronger Materials with Precision

- Why does the reactive sintering process of RuTi alloys rely on the high vacuum environment provided by a vacuum hot press furnace? Essential for Purity and Density

- Why is hot pressing ideal for critical applications in industries like aerospace and automotive? Achieve Unmatched Component Density and Reliability

- Why is Vacuum Hot Press equipment considered a cornerstone of modern manufacturing? Unlock Superior Material Density and Purity