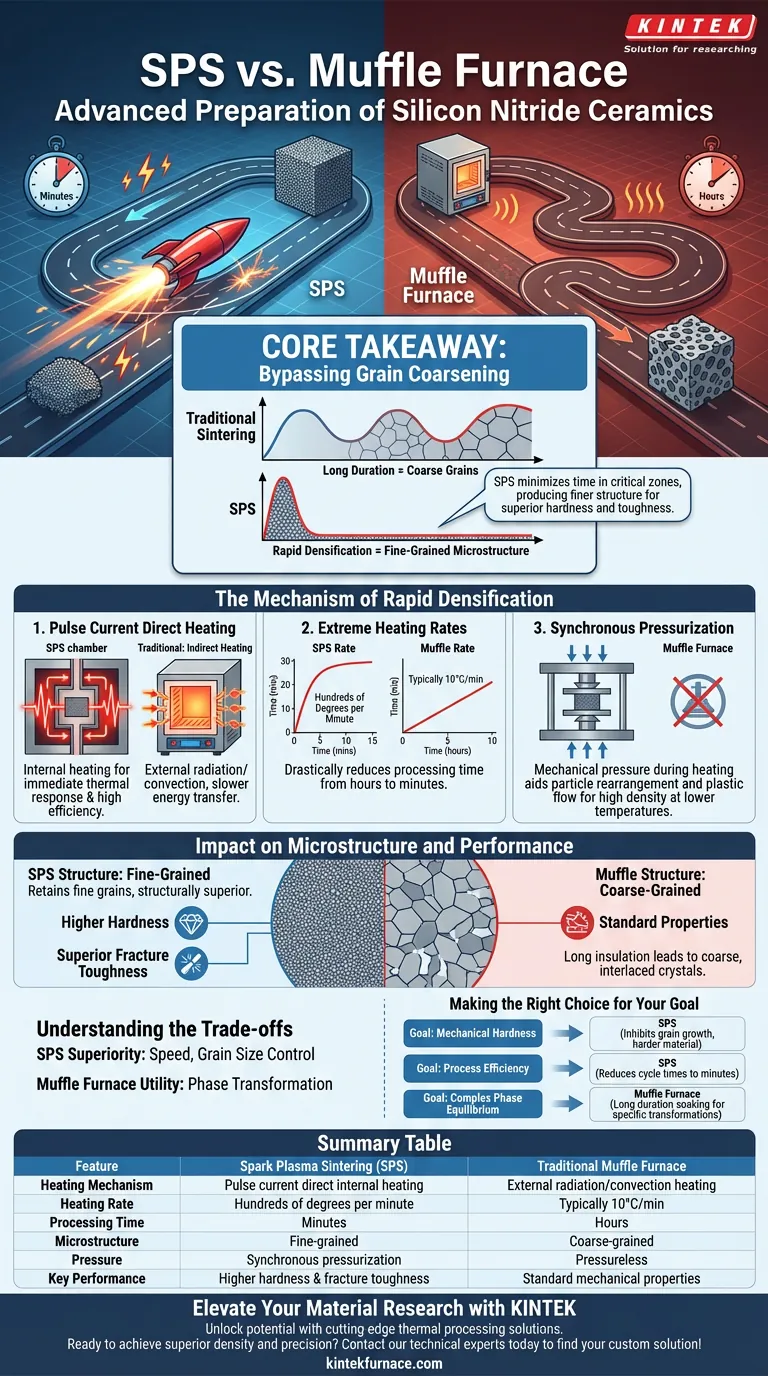

Spark Plasma Sintering (SPS) fundamentally outperforms traditional muffle furnaces for silicon nitride preparation by leveraging pulse current direct heating combined with synchronous pressurization. While a muffle furnace relies on slow, indirect thermal energy, an SPS system generates internal heat to achieve rates of several hundred degrees per minute, enabling rapid densification that traditional methods cannot match.

Core Takeaway The distinct advantage of SPS lies in its ability to bypass the intermediate temperature zones where grain coarsening typically occurs. By minimizing the time spent at these critical temperatures, SPS produces a fine-grained microstructure that delivers superior hardness and fracture toughness compared to the coarser materials produced by conventional sintering.

The Mechanism of Rapid Densification

Pulse Current Direct Heating

Unlike a laboratory muffle furnace, which heats samples from the outside in via radiation or convection, an SPS system utilizes pulse current to directly heat the mold and sample.

This internal heating mechanism allows for immediate thermal response and high energy efficiency.

Extreme Heating Rates

A traditional high-temperature furnace often operates with controlled, slow heating rates (e.g., 10°C/min) to maintain stability.

In contrast, SPS achieves heating rates of several hundred degrees per minute. This capability drastically reduces the overall processing time from hours to mere minutes.

Synchronous Pressurization

SPS integrates mechanical pressure during the heating phase. This synchronous pressurization aids in particle rearrangement and plastic flow.

It allows the silicon nitride to achieve high density at lower temperatures than would be required in a pressureless muffle furnace.

Impact on Microstructure and Performance

Bypassing Grain Coarsening

The most critical metallurgical advantage of SPS is its speed. In a traditional furnace, long dwell times allow grains to grow excessively (coarsen) before the material is fully dense.

SPS heats the material so quickly that it bypasses the intermediate temperature zones responsible for this uncontrolled grain growth.

Preservation of Fine-Grained Structure

Because the densification process is completed in a very short duration, the silicon nitride retains a fine-grained microstructure.

This is structurally superior to the coarse, interlaced crystal structures often resulting from the long-duration insulation typical of conventional sintering.

Superior Mechanical Properties

The direct result of this refined microstructure is enhanced mechanical performance.

SPS-produced silicon nitride exhibits higher hardness and superior fracture toughness, making it more suitable for high-performance engineering applications than conventionally sintered counterparts.

Understanding the Trade-offs

Phase Transformation Requirements

While SPS is superior for densification speed and grain size control, traditional furnaces still hold specific utility.

High-performance silicon nitride often requires a transition from the alpha-phase to the beta-phase to develop specific crystal structures (e.g., interlaced columnar crystals). This process traditionally requires long-duration insulation (e.g., 120 minutes) and high nitrogen pressure, conditions that a standard fast-firing SPS cycle may need to be specifically adapted to mimic.

Making the Right Choice for Your Goal

To determine whether SPS is the correct tool for your specific silicon nitride application, evaluate your primary objectives:

- If your primary focus is mechanical hardness: SPS is the superior choice, as the rapid densification inhibits grain growth, resulting in a harder, fine-grained material.

- If your primary focus is process efficiency: SPS offers a distinct advantage by reducing cycle times from hours to minutes through pulse current heating.

- If your primary focus is complex phase equilibrium: A traditional furnace may be necessary if your specific material grade requires long-duration soaking to facilitate slow alpha-to-beta phase transformation.

Ultimately, for applications demanding high fracture toughness and hardness, SPS provides a microstructural quality that conventional muffle furnaces cannot replicate.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Muffle Furnace |

|---|---|---|

| Heating Mechanism | Pulse current direct internal heating | External radiation/convection heating |

| Heating Rate | Hundreds of degrees per minute | Typically 10°C/min |

| Processing Time | Minutes | Hours |

| Microstructure | Fine-grained (inhibits coarsening) | Coarse-grained (due to long dwell) |

| Pressure | Synchronous pressurization | Pressureless (usually) |

| Key Performance | Higher hardness & fracture toughness | Standard mechanical properties |

Elevate Your Material Research with KINTEK

Unlock the full potential of your advanced ceramics with KINTEK’s cutting-edge thermal processing solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as advanced sintering technologies. All our laboratory high-temp furnaces are fully customizable to meet your unique research or production needs.

Ready to achieve superior density and precision? Contact our technical experts today to find your custom solution!

Visual Guide

References

- ESTIMATION OF VOLATILE MATTER, HEATING VALUE, POROXIMATE, ULTIMATE AND STRUCTURAL COMPOSITION OF BIOMASS (ELEPHANT GRASS). DOI: 10.56726/irjmets48152

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the advantages of benchtop SPS/FAST for titanium R&D? Accelerate Your Microstructural Engineering

- Can you use a heat press for laminating? A Practical Guide for DIY and Crafting

- What role do vacuum hot press furnaces play in advanced materials development? Forge High-Density, Pure Materials

- What role does a high-temperature vacuum pressing furnace play in lithium disilicate fabrication? Expert Insights

- What are the technical advantages of using a Spark Plasma Sintering (SPS) system for Barium Titanate ceramics?

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- How does the pressure control function in a vacuum hot pressing sintering furnace influence ceramic tool materials?

- How does a Vacuum Hot Press Furnace facilitate Al-Ti-Zr synthesis? Achieve Near-Theoretical Material Density