At its core, vacuum laminating is a manufacturing process that uses atmospheric pressure as a powerful clamp to consolidate layers of composite material. By placing a resin-infused part inside a sealed bag and evacuating the air, the process removes trapped gases and applies uniform pressure across the entire surface, resulting in a dense, strong, and lightweight final product.

The fundamental insight is that vacuum laminating isn't about "sucking" the part into shape. It's about removing the internal air so that the immense weight of the Earth's atmosphere—approximately 14.7 pounds per square inch (psi)—can press down and consolidate the composite layers.

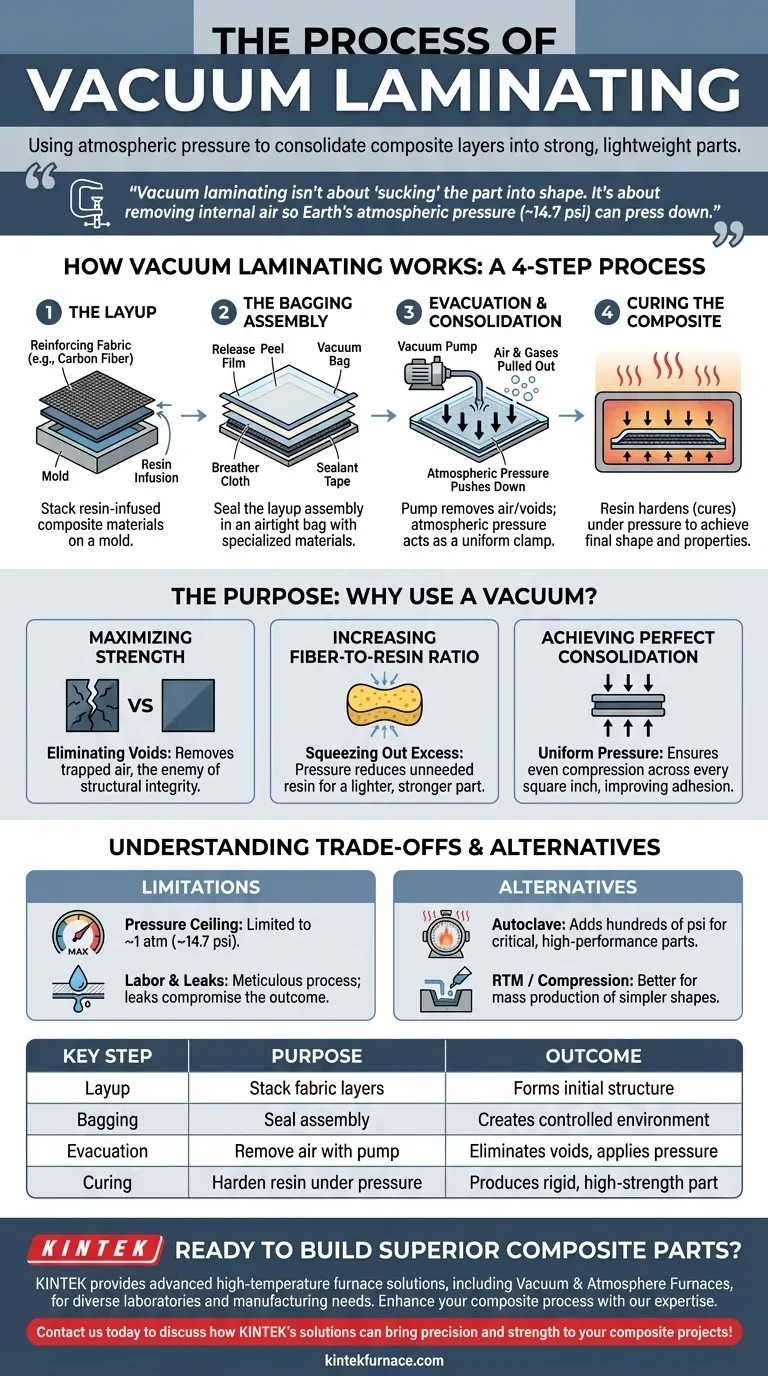

How Vacuum Laminating Works

The process transforms a stack of flexible, resin-coated fabrics into a rigid, unified structure. It relies on a pressure differential between the inside and outside of a sealed bag.

Step 1: The Layup

The first step is creating the layup, which is the stack of composite materials. This typically involves layers of reinforcing fabric (like carbon fiber, fiberglass, or aramid) that have been impregnated with a liquid resin (like epoxy or polyester).

Step 2: The Bagging Assembly

The layup is placed on a mold and covered with a sequence of specialized materials. This "vacuum stack" includes a release film to prevent sticking, a peel ply for a textured surface finish, and a breather cloth to create a clear path for air to be extracted.

Finally, the entire assembly is sealed inside a flexible, airtight vacuum bag.

Step 3: Evacuation and Consolidation

A vacuum pump is connected to the bag via a port. As the pump draws out the air, two critical things happen simultaneously.

First, any trapped air and volatile gases from within the resin and between the composite layers are pulled out. These pockets of air, known as voids, are a primary source of weakness in a finished part.

Second, with a near-perfect vacuum inside the bag, the full force of atmospheric pressure pushes down on the outside. This external pressure acts as a perfectly uniform clamp, compressing the layers together. This is called consolidation.

Step 4: Curing the Composite

While held under this vacuum pressure, the resin undergoes a chemical reaction to harden, or cure. This can occur at room temperature for some resin systems or be accelerated with heat in an oven.

The constant pressure ensures the part maintains its shape and density throughout the curing process, squeezing out excess resin and achieving a high fiber-to-resin ratio, which is critical for performance.

The Purpose: Why Use a Vacuum?

The use of a vacuum is not arbitrary; it solves the most fundamental challenges in creating high-performance composites.

Maximizing Strength by Eliminating Voids

Voids are the enemy of a strong composite. By removing trapped air, vacuum pressure drastically reduces or eliminates these weak points, ensuring the part's structural integrity.

Increasing the Fiber-to-Resin Ratio

Resin gives a composite its shape and holds the fibers together, but the fibers provide the actual strength and stiffness. The pressure from the vacuum squeezes out excess, unneeded resin, making the final part lighter and proportionately stronger.

Achieving Perfect Consolidation

Unlike a mechanical clamp that only applies pressure at specific points, atmospheric pressure is perfectly distributed. This ensures every square inch of the laminate is compressed evenly, leading to superior adhesion between layers and a solid, dense final part.

Understanding the Trade-offs

While powerful, vacuum laminating is not the solution for every scenario. It is crucial to understand its limitations.

The Pressure Ceiling

The maximum clamping force you can achieve is limited to one atmosphere of pressure (~14.7 psi or 1 bar). For extremely thick or performance-critical components, such as primary aerospace structures, this may not be enough.

In those cases, a similar process is performed inside an autoclave—a pressurized, heated vessel that can add hundreds of psi of external pressure on top of the initial vacuum.

Labor and Leak Prevention

Vacuum bagging is a meticulous, hands-on process. Achieving a perfect, leak-free seal around the entire part requires skill and care. Even a minuscule leak can compromise the vacuum and ruin the part during the hours-long curing cycle.

Distinguishing from Other Vacuum Processes

It's important not to confuse vacuum laminating with other manufacturing techniques that use a vacuum. For example, vacuum sintering is a high-heat process used to fuse metallic or ceramic powders in a vacuum furnace, which is fundamentally different from laminating layers of fiber and resin.

Making the Right Choice for Your Goal

Selecting the right process depends entirely on your project's requirements for performance, cost, and volume.

- If your primary focus is producing high-quality prototypes, custom parts, or low-volume production: Vacuum laminating is an excellent and highly accessible method for creating strong, lightweight components without investing in expensive tooling.

- If your primary focus is ultimate performance for aerospace or high-end racing parts: Vacuum bagging is a necessary first step, but it is typically combined with an autoclave to achieve the absolute highest density and lowest void content.

- If your primary focus is mass production of simpler composite shapes: More automated processes like Resin Transfer Molding (RTM) or compression molding are often more cost-effective and faster at scale.

By understanding its principles and limitations, you can effectively leverage vacuum lamination to create superior composite parts.

Summary Table:

| Key Step | Purpose | Outcome |

|---|---|---|

| Layup | Stack resin-infused fabric layers | Forms the initial part structure |

| Bagging | Seal assembly in an airtight bag | Creates a controlled environment for pressure |

| Evacuation | Remove air with a vacuum pump | Eliminates voids and applies uniform pressure |

| Curing | Harden resin under pressure | Produces a rigid, high-strength composite part |

Ready to Build Superior Composite Parts?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you are prototyping, in low-volume production, or require ultimate performance for aerospace or racing applications, our expertise in thermal processing can enhance your composite manufacturing process.

Contact us today to discuss how KINTEK's solutions can bring precision and strength to your composite projects!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

People Also Ask

- How does tailored heat and pressure control benefit hot pressing? Achieve Superior Material Density and Strength

- What is a vacuum press and what are its primary uses? Unlock High-Performance Material Processing

- What are the applications of hot pressing? Achieve Maximum Material Performance

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing