The mechanical pressure applied by the hot pressing mechanism acts as a critical driver for densification, moving beyond simple heating to actively force physical changes within the material. By compressing the powder matrix during high-temperature sintering, this pressure forces particles to rearrange and overcomes the natural resistance to diffusion. The immediate result is the effective elimination of microscopic pores, pushing the material toward near-zero porosity.

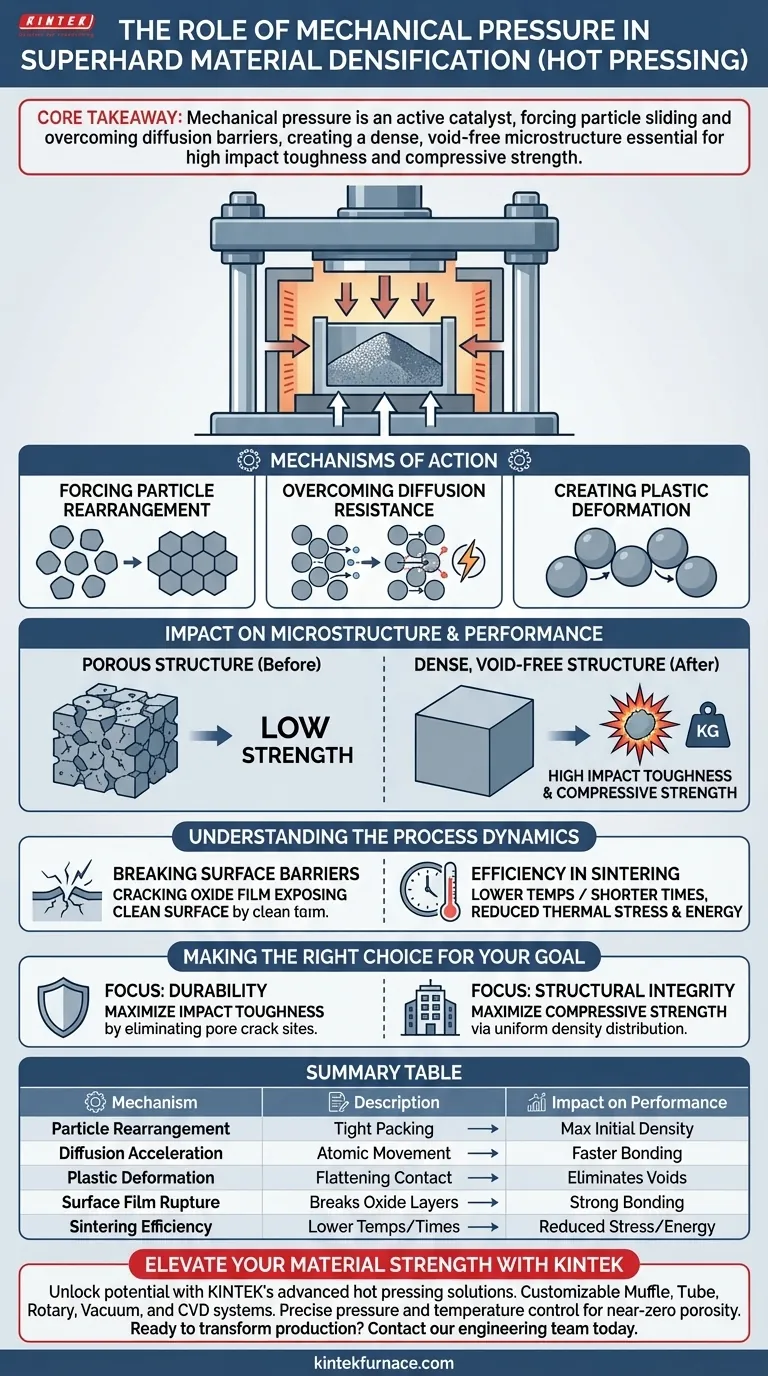

Core Takeaway Mechanical pressure serves as an active catalyst that forces particle sliding and overcomes diffusion barriers, rather than waiting for passive sintering to occur. This direct force creates a dense, void-free microstructure that is essential for achieving high impact toughness and compressive strength in superhard materials.

Mechanisms of Action

Forcing Particle Rearrangement

The primary function of the applied mechanical pressure is to physically compel the powder particles to move. During the initial stages of sintering, particles often sit in a loose arrangement. The external force overcomes friction, causing the particles to slide and rearrange into a significantly tighter packing configuration.

Overcoming Diffusion Resistance

Diffusion—the movement of atoms to bond particles together—naturally faces resistance. Mechanical pressure provides the necessary energy to overcome this resistance. This ensures that atoms can migrate effectively across particle boundaries, accelerating the bonding process.

Creating Plastic Deformation

Beyond simple movement, the pressure is strong enough to cause plastic deformation in the particles. This deformation increases the contact area between individual granules. By flattening contact points, the process eliminates gaps that would otherwise remain as voids.

Impact on Microstructure and Performance

Elimination of Microscopic Pores

The most significant structural outcome of this pressure is the eradication of porosity. The force squeezes out voids and compels the material matrix (whether solid or semi-solid) to flow into any remaining gaps. This results in a microstructure with porosity levels close to zero, effectively creating a solid, continuous block.

Enhancing Mechanical Properties

The density achieved through this method directly translates to superior performance. Because the microstructure lacks the weak points caused by pores, the material exhibits significantly higher impact toughness. Additionally, the compact structure dramatically improves compressive strength, allowing the product to withstand immense loads without failure.

Understanding the Process Dynamics

Breaking Surface Barriers

In many material systems, particles are coated in oxide films that hinder bonding. The shear force generated by mechanical pressure helps rupture these films. This exposes clean surfaces, promoting direct particle-to-particle contact and stronger diffusion bonding.

Efficiency in Sintering

Pressure-assisted sintering is not just more effective; it is often more efficient. The application of force allows for densification at lower temperatures or shorter holding times compared to pressureless methods. This reduces the thermal stress on the material and lowers energy consumption while still achieving high relative density.

Making the Right Choice for Your Goal

Mechanical pressure is the defining factor in distinguishing high-performance superhard materials from standard sintered products.

- If your primary focus is Durability: High mechanical pressure is essential to eliminate pores that act as crack initiation sites, thereby maximizing impact toughness.

- If your primary focus is Structural Integrity: The forced rearrangement ensures a uniform density distribution, which is critical for achieving maximum compressive strength.

By integrating mechanical pressure, you transform a loose powder assembly into a cohesive, high-strength component capable of surviving extreme operational environments.

Summary Table:

| Mechanism of Action | Description | Impact on Performance |

|---|---|---|

| Particle Rearrangement | Forces loose powders into a tighter packing configuration | Maximizes initial density |

| Diffusion Acceleration | Overcomes resistance to atomic movement across boundaries | Accelerates particle bonding |

| Plastic Deformation | Flattens contact points to increase granule contact area | Eliminates residual voids |

| Surface Film Rupture | Breaks oxide layers through mechanical shear force | Promotes clean, strong bonding |

| Sintering Efficiency | Enables densification at lower temperatures/shorter times | Reduces thermal stress & energy |

Elevate Your Material Strength with KINTEK

Unlock the full potential of your superhard materials with KINTEK’s advanced hot pressing solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your specific lab and high-temperature furnace needs.

Whether you are aiming for near-zero porosity or superior impact toughness, our systems provide the precise pressure and temperature control necessary for mission-critical densification.

Ready to transform your production? Contact our engineering team today to discuss your unique project requirements and see how our tailored thermal technology can optimize your results.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the difference between hot pressing and sintering? Choose the Right Process for Your Materials

- What are the advantages of Spark Plasma Sintering (SPS)? Enhance Cu2Se Densification and Thermoelectric Performance

- How does a vacuum hot press furnace facilitate the densification of Al-Si/graphite? Achieve 100% Thermal Density

- How does hot pressing differ from ordinary cold pressing and sintering? Unlock Superior Material Performance

- What role do graphite molds play in the vacuum hot press sintering process of IZO targets? Ensuring Purity and Density

- What is the function of Molybdenum Disulfide (MoS2) coating on molds during vacuum hot press sintering? Protect Your Samples and Molds from Damage

- What are the technical advantages of using an SPS sintering furnace? Elevate Al2O3-TiC Material Performance

- Why are graphite molds selected for the vacuum hot press sintering of aluminum-based composites? Expert Insights