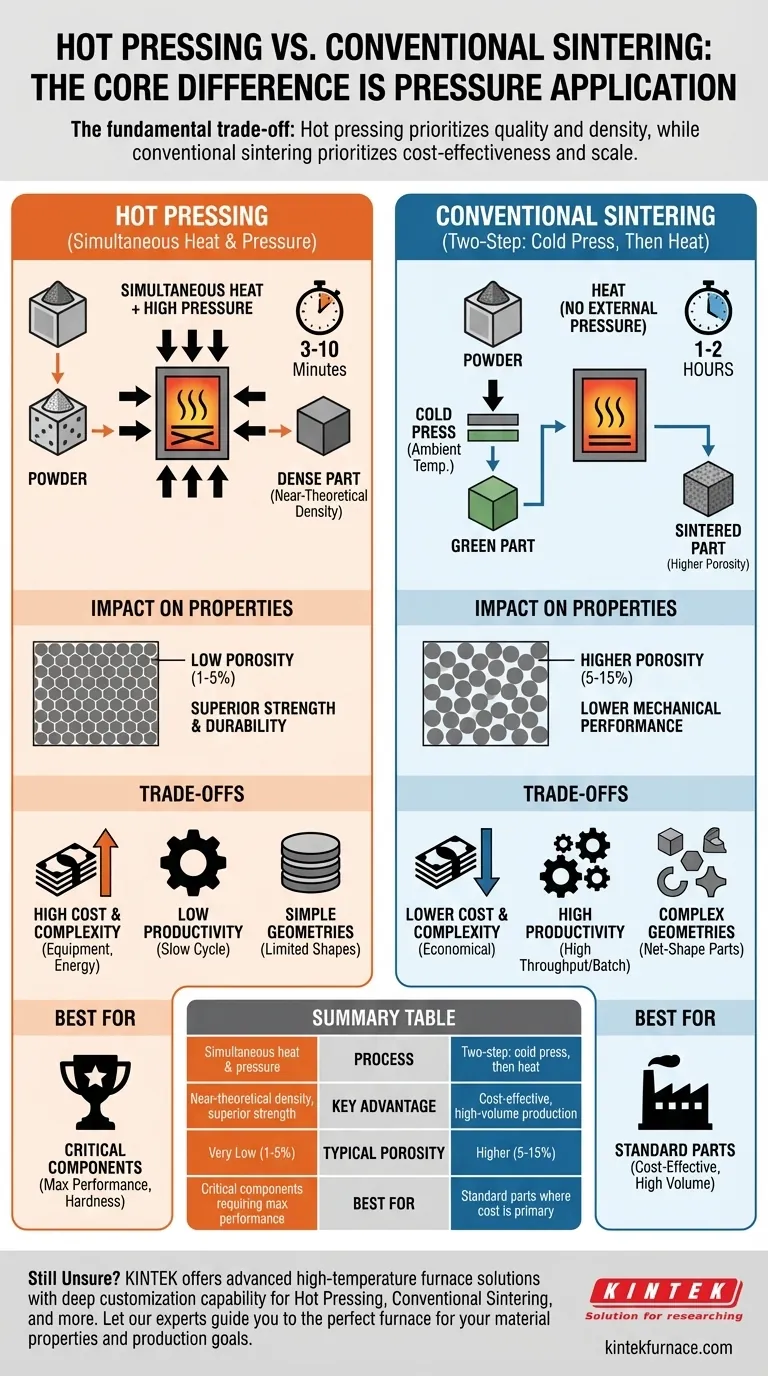

At its core, the difference between hot pressing and sintering lies in when pressure is applied. Hot pressing is a specific type of sintering that applies high pressure and high temperature simultaneously to a powder compact. In contrast, conventional sintering involves first compacting a powder at room temperature (cold pressing) and then heating it in a furnace without external pressure.

While both processes aim to fuse powder particles into a solid mass, the fundamental trade-off is clear: hot pressing prioritizes final material quality over production cost and speed, whereas conventional sintering prioritizes cost-effectiveness and scale at the expense of ultimate density.

The Core Process Difference: When Pressure is Applied

To understand the results, you must first understand the fundamental divergence in the processes themselves. The key is the interplay between heat and mechanical force.

Hot Pressing: A Simultaneous Operation

Hot pressing is considered an activated sintering process. The powdered material is placed into a die, which is then heated while simultaneously being subjected to high external pressure.

This combination of forces accelerates the entire densification process, achieving a solid part in as little as 3-10 minutes.

Conventional Sintering: A Two-Step Method

Conventional sintering is a sequential process. First, the powder is compacted into a desired shape using a press at ambient temperature, an action known as cold pressing.

This "green" part is then ejected from the press and heated in a separate furnace. During this heating stage, no external pressure is applied, and the particles bond through atomic diffusion alone, a process that can take one to two hours.

Impact on Material Properties: Density and Strength

The process difference directly dictates the final quality of the part, primarily by controlling its internal structure.

The Goal: Minimizing Porosity

In powder metallurgy, the enemy of performance is porosity, or the empty space between fused particles. These voids act as stress concentration points and are the primary source of mechanical failure.

Why Hot Pressing Creates Denser Parts

By applying intense pressure during heating, hot pressing physically forces particles together, closing off voids and promoting more complete atomic bonding.

This results in a material with extremely low porosity, often achieving near-theoretical density. The direct consequence is significantly improved mechanical properties, including higher strength and durability.

The Result of Conventional Sintering

In conventional sintering, the absence of external pressure during heating means the process relies solely on temperature to drive particle bonding. This is less efficient at eliminating voids.

Consequently, conventionally sintered parts inherently retain a higher degree of porosity, which can negatively impact their overall mechanical performance compared to hot-pressed equivalents.

Understanding the Trade-offs: Cost vs. Quality

Choosing between these methods is not about which is "better" in a vacuum, but which is appropriate for a specific application. This decision is driven by trade-offs between cost, volume, and performance.

The Cost of Complexity

Hot pressing equipment is significantly more complex and expensive. The dies must withstand both extreme temperatures and high pressures simultaneously, requiring robust and costly materials. This, combined with higher energy consumption, drives up the per-part cost.

Productivity and Throughput

While the densification phase of hot pressing is very fast, the overall cycle is slow. Each part requires the entire press and furnace assembly to heat up, press, and cool down.

Conventional sintering, by contrast, allows for much higher throughput. A single furnace can sinter hundreds or thousands of cold-pressed parts at once, making it far more cost-effective for large-scale production.

Geometric Limitations

The need to press and heat in a single, robust die generally limits hot pressing to simpler shapes like discs, blocks, or cylinders. The cold-pressing step in conventional sintering allows for the creation of more complex net-shape parts before they enter the furnace.

Making the Right Choice for Your Application

Your final decision must be guided by the specific requirements of your component and your business.

- If your primary focus is maximum performance and density: Hot pressing is the superior choice for critical components where mechanical strength, hardness, and durability are non-negotiable.

- If your primary focus is cost-effective, high-volume production: Conventional sintering is the more economical and scalable path for parts in less demanding applications.

Ultimately, the choice depends on a clear understanding of the balance between the cost of production and the required performance of the final part.

Summary Table:

| Feature | Hot Pressing | Conventional Sintering |

|---|---|---|

| Process | Simultaneous heat & pressure | Two-step: cold press, then heat |

| Key Advantage | Near-theoretical density, superior strength | Cost-effective, high-volume production |

| Typical Porosity | Very Low (1-5%) | Higher (5-15%) |

| Best For | Critical components requiring maximum performance | Standard parts where cost is a primary driver |

Still Unsure Which Process is Best for Your Application?

Choosing between hot pressing and sintering is critical to achieving your desired material properties and production goals. KINTEK is here to guide you.

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Let our experts help you select or customize the perfect furnace for your specific needs.

Contact KINTEK today to discuss your project and unlock the full potential of your materials.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength