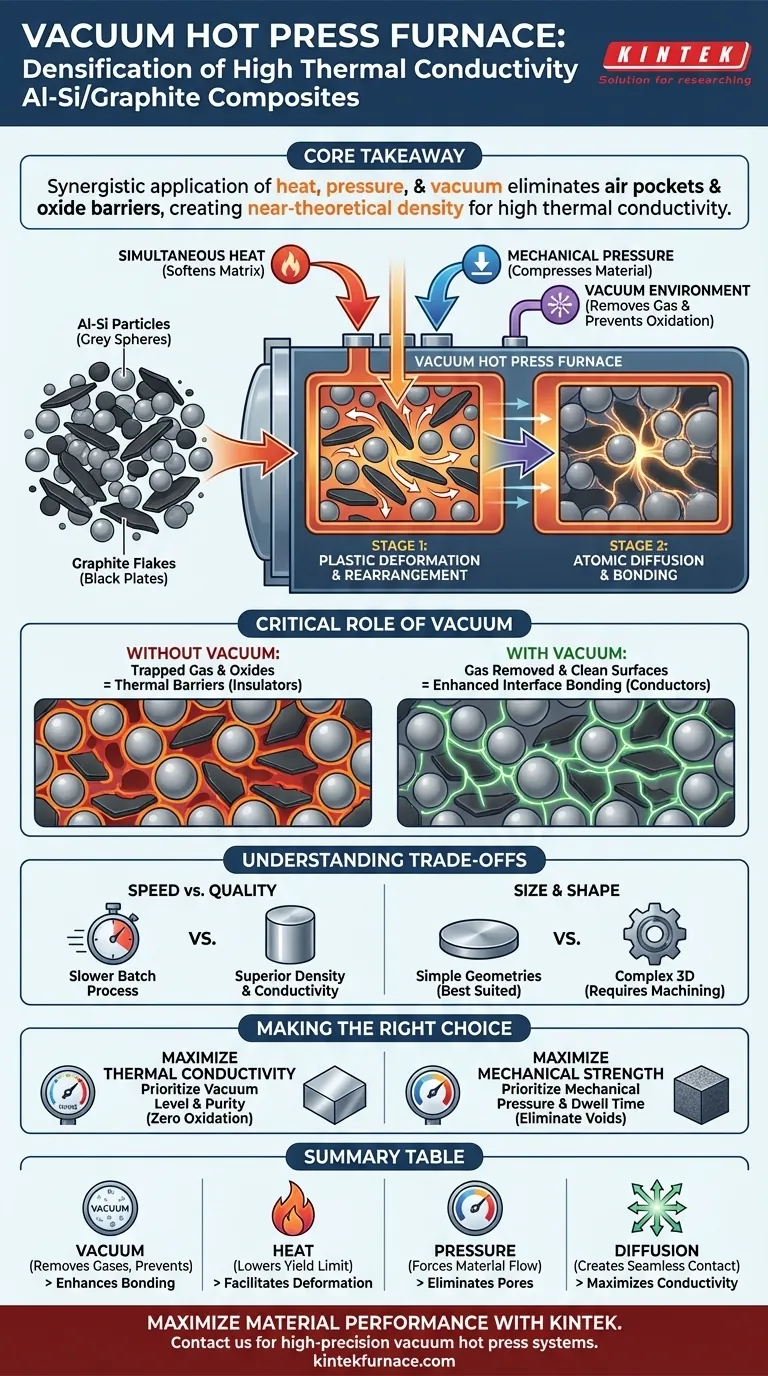

The facilitation of densification in Al-Si/graphite composites is achieved through the simultaneous application of a high-temperature field and mechanical pressure within a vacuum environment. This process utilizes the synergistic effect of heat and force to eliminate microscopic pores, promote the plastic deformation of the aluminum-silicon matrix, and rearrange particles into a tightly packed structure.

Core Takeaway Achieving high thermal conductivity requires eliminating air pockets and oxide barriers that act as insulators. A vacuum hot press furnace solves this by mechanically forcing the matrix to flow into voids while simultaneously stripping away gases and preventing oxidation, resulting in a composite with near-theoretical density.

The Synergistic Mechanics of Densification

Simultaneous Heat and Pressure

The primary driver of densification is the synergistic effect of thermal energy and mechanical force. While heat softens the aluminum-silicon alloy, lowering its yield limit, the mechanical pressure actively compresses the material.

Plastic Deformation

Under these conditions, the Al-Si alloy particles undergo significant plastic deformation. The material becomes pliable enough to change shape without fracturing, allowing it to conform perfectly around the graphite reinforcement.

Particle Rearrangement

The applied pressure forces a rearrangement of particles. The softened metal matrix is physically moved to fill the interstitial spaces between the graphite components, effectively closing the gaps that would otherwise remain in a static sintering process.

The Critical Role of the Vacuum Environment

Elimination of Microscopic Pores

A vacuum environment is essential for removing gases trapped in the interstitial spaces between powder particles. By evacuating these gases before and during the pressing phase, the furnace prevents the formation of internal gas pockets that would result in porosity and reduced thermal conductivity.

Prevention of Matrix Oxidation

Aluminum has a high affinity for oxygen, forming oxide layers that act as thermal barriers. The vacuum environment prevents the oxidation of the Al-Si powder at high temperatures, ensuring the purity of the matrix and facilitating direct metal-to-graphite contact.

Enhanced Interface Bonding

High thermal conductivity relies on a seamless interface between the metal matrix and the graphite. The combination of clean surfaces (due to vacuum) and high pressure induces atomic diffusion, creating a strong bond that facilitates efficient heat transfer.

Understanding the Trade-offs

Production Speed vs. Quality

While vacuum hot pressing yields superior density and conductivity compared to cold pressing, it is a slower, batch-oriented process. The cycle times required for heating, pressing, and cooling in a vacuum are significantly longer than conventional sintering methods.

Size and Shape Limitations

The mechanical nature of the press creates geometric constraints. The process is best suited for simple, flat shapes or discs; producing complex 3D geometries often requires extensive post-process machining, which can be difficult given the abrasive nature of graphite composites.

Making the Right Choice for Your Goal

To maximize the performance of your Al-Si/graphite composite, align your processing parameters with your specific engineering requirements.

- If your primary focus is Maximum Thermal Conductivity: Prioritize the vacuum level and purity to ensure zero oxidation at the interface, as oxides are the primary bottleneck for heat transfer.

- If your primary focus is Mechanical Strength: Focus on maximizing the mechanical pressure and dwell time to ensure complete plastic deformation and the absolute elimination of microscopic voids.

By leveraging the dual power of thermal softening and mechanical compression in a protected environment, you transform a porous mixture into a high-performance, fully dense composite.

Summary Table:

| Feature | Impact on Densification | Benefit for Al-Si/Graphite |

|---|---|---|

| Vacuum Environment | Removes trapped gases and prevents oxidation | Enhances interface bonding and purity |

| Simultaneous Heat | Lowers yield limit of Al-Si alloy | Facilitates easy plastic deformation |

| Mechanical Pressure | Forces material into interstitial gaps | Eliminates microscopic pores/voids |

| Atomic Diffusion | Creates seamless metal-to-graphite contact | Maximizes thermal conductivity |

Maximize Your Material Performance with KINTEK

Are you looking to achieve near-theoretical density and peak thermal conductivity for your advanced composites? KINTEK’s high-precision vacuum hot press systems are designed to provide the perfect synergy of thermal control and mechanical force. Backed by expert R&D and world-class manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique lab and industrial needs.

Take the next step in material excellence—Contact KINTEK today to discuss your specific high-temperature furnace requirements with our specialists!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is high-strength graphite selected for vacuum hot pressing of thermoelectric alloys? High-Heat Stability Expert

- What is the necessity of maintaining a high vacuum environment during AZ31 sintering? Prevent Oxidation and Porosity

- What is the working principle of a vacuum hot press sintering furnace? Master Dense Material Creation

- What is the primary function of a hot-pressing furnace in SiC bicrystal synthesis? Achieve Precision Atomic Bonding

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- Why is high-precision temperature control essential for the vacuum hot press furnace? Optimize Ti-Al3Ti Composites

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What is the use of a hot press? Achieve Perfect Bonding & High-Performance Materials