Spark Plasma Sintering (SPS) equipment functions as a specialized consolidation tool that transforms aluminum alloy scrap into high-performance materials without melting them. By simultaneously applying axial pressure and high-intensity pulsed electric current, the equipment fuses scrap particles in a solid state to create dense, strong recycled products.

Core Takeaway Traditional recycling often degrades material properties through melting. SPS avoids this by using a solid-state recovery process that leverages Joule heating and pressure to bond aluminum scrap, resulting in recycled alloys that retain superior structural integrity and mechanical strength.

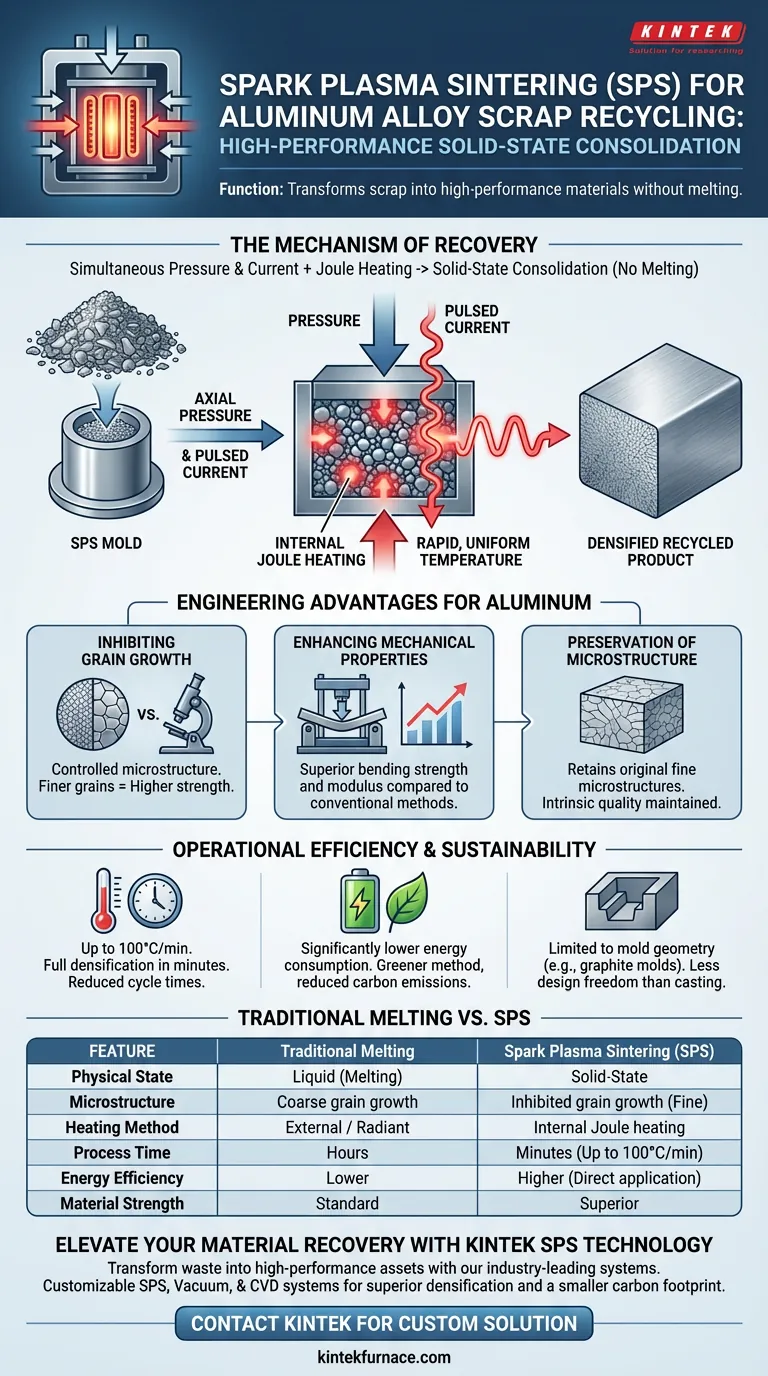

The Mechanism of Recovery

Simultaneous Pressure and Current

The defining feature of SPS equipment is the concurrent application of two forces. It compresses the aluminum scrap using axial pressure while simultaneously passing a high-intensity pulsed current through the material and the mold.

Joule Heating

Unlike external heating methods, SPS generates heat internally through Joule heating. This occurs as the pulsed current encounters resistance within the scrap particles and the mold, allowing for rapid and uniform temperature distribution.

Solid-State Consolidation

The equipment operates entirely within the solid-state regime. This means the aluminum scrap never reaches its melting point during the recycling process, preventing the chemical segregation often seen in liquid casting.

Engineering Advantages for Aluminum

Inhibiting Grain Growth

A critical function of SPS is its ability to control the microstructure of the recycled material. The combination of pressure and rapid heating significantly inhibits grain growth. In metallurgy, finer grains generally equate to higher strength.

Enhancing Mechanical Properties

Because the process preserves a finer microstructure, the resulting material exhibits superior mechanical performance. Specifically, SPS enhances the bending strength and modulus of the sintered aluminum compared to materials processed through conventional means.

Preservation of Microstructure

SPS allows for the partial preservation of original fine microstructures found in the scrap. By avoiding the chaotic reorganization of atoms that happens during melting, the intrinsic quality of the original alloy is maintained.

Operational Efficiency and Trade-offs

High Heating Rates

SPS systems are capable of extremely high heating rates, potentially reaching 100°C per minute. This allows the equipment to achieve full densification of the scrap within minutes, drastically reducing cycle times compared to conventional sintering.

Energy and Carbon Reduction

By eliminating the need to melt the metal, SPS acts as a more sustainable alternative. It significantly reduces energy consumption and associated carbon emissions, making it a "greener" method for recovering value from waste streams.

Geometric Constraints

While SPS offers superior material properties, it is a sintering process typically performed in molds (often graphite). This implies that while you gain material strength, you are generally limited to shapes defined by the mold geometry, unlike casting which can flow into complex voids.

Making the Right Choice for Your Goal

This technology represents a shift from simple waste melting to high-value material recovery. Here is how to assess its fit for your needs:

- If your primary focus is mechanical performance: Leverage SPS to inhibit grain growth, ensuring your recycled aluminum achieves maximum bending strength and modulus.

- If your primary focus is process efficiency: Utilize the high heating rates of SPS to densify scrap in minutes rather than hours, increasing throughput.

- If your primary focus is sustainability: Adopt SPS to lower the carbon footprint of your recycling stream by eliminating the energy-intensive melting phase.

SPS converts aluminum scrap from a waste liability into a high-performance asset through precise, solid-state engineering.

Summary Table:

| Feature | Traditional Melting | Spark Plasma Sintering (SPS) |

|---|---|---|

| Physical State | Liquid (Melting) | Solid-State |

| Microstructure | Coarse grain growth | Inhibited grain growth (Fine) |

| Heating Method | External / Radiant | Internal Joule heating |

| Process Time | Hours | Minutes (Up to 100°C/min) |

| Energy Efficiency | Lower (High heat loss) | Higher (Direct energy application) |

| Material Strength | Standard mechanical properties | Superior bending strength & modulus |

Elevate Your Material Recovery with KINTEK SPS Technology

Don't let valuable aluminum scrap lose its integrity through traditional melting processes. KINTEK provides industry-leading Spark Plasma Sintering (SPS) systems designed to transform waste into high-performance assets.

Backed by expert R&D and precision manufacturing, our lab high-temperature furnaces—including SPS, Vacuum, and CVD systems—are fully customizable to meet your unique metallurgical needs. Partner with KINTEK to achieve superior densification, finer microstructures, and a smaller carbon footprint.

Ready to optimize your recycling efficiency? Contact KINTEK today to discuss your custom solution!

Visual Guide

References

- Reinosuke Kusano, Yukihiro Kusano. Applications of Plasma Technologies in Recycling Processes. DOI: 10.3390/ma17071687

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What roles do high-strength graphite molds play during the hot-pressing sintering of TiAl-SiC composites?

- What is a vacuum press and what are its primary uses? Unlock High-Performance Material Processing

- Why is a high vacuum system necessary for diffusion bonding RAFM steel? Ensure High-Strength Joint Integrity

- Why is a Vacuum Hot Press (VHP) furnace preferred over stir casting? Achieve Near-Theoretical Density for Composites

- How does a vacuum press work? Harness Atmospheric Pressure for Perfect Clamping

- What role do graphite molds play in the vacuum hot press sintering process of IZO targets? Ensuring Purity and Density

- Why is adjustable temperature important in a vacuum hot press furnace? Unlock Precision for Superior Materials Processing

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing