Vacuum hot pressing (VHP) provides a critical advantage over casting by maintaining a solid-state environment, effectively bypassing the severe chemical degradation that occurs when aluminum is melted in the presence of carbon-based reinforcements.

By applying simultaneous high pressure and heat below the melting point, VHP achieves metallurgical bonding and high densification while preventing the formation of brittle reaction products that plague liquid casting processes.

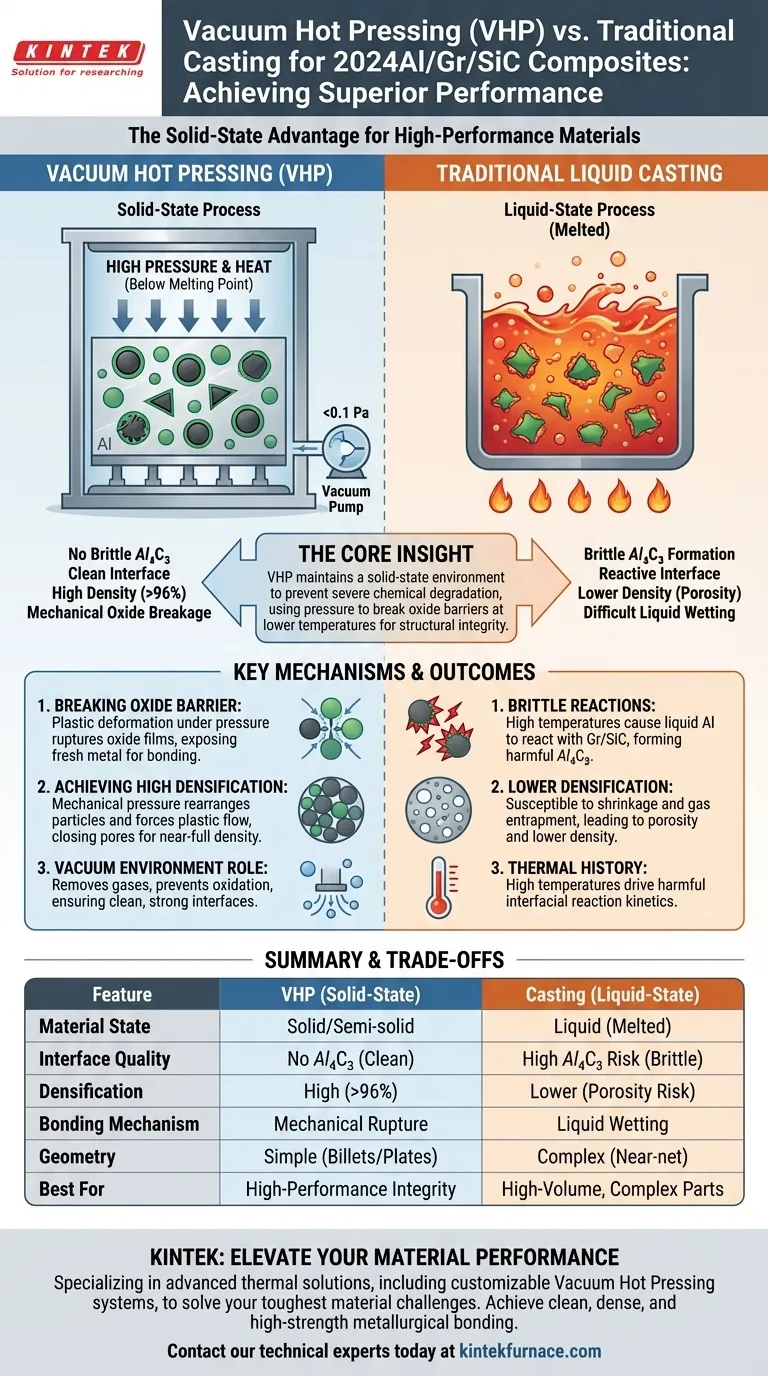

The Core Insight Manufacturing 2024Al/Gr/SiC composites requires navigating a delicate trade-off between bonding and chemical stability. VHP solves this by using pressure to mechanically break oxide barriers at lower temperatures, ensuring structural integrity where liquid casting would otherwise dissolve the reinforcements into brittle contaminants.

The Problem with Liquid State Processing

Preventing Brittle Interfacial Reactions

The primary danger in traditional casting is the high temperature required to melt the aluminum matrix (typically 750-850°C).

At these temperatures, liquid aluminum reacts aggressively with Graphite (Gr) and Silicon Carbide (SiC).

This reaction creates aluminum carbide ($Al_4C_3$), a brittle compound that severely degrades the mechanical properties and thermal conductivity of the final composite.

Controlling the Thermal History

VHP operates at a significantly lower temperature, keeping the aluminum in a solid or semi-solid state.

This "low-temperature" approach effectively inhibits the chemical kinetics required for harmful interfacial reactions.

By avoiding the liquid phase, you preserve the integrity of the Gr and SiC reinforcements.

Mechanisms of Superior Bonding

Breaking the Oxide Barrier

Aluminum particles are naturally coated with a stubborn oxide film that inhibits bonding with other materials.

In liquid casting, wetting these reinforcements is difficult without excessive heat.

VHP solves this through plastic deformation. The combination of high heat and axial pressure deforms the aluminum particles, physically rupturing the oxide film and exposing fresh metal for metallurgical bonding.

Achieving High Densification

Standard vacuum sintering often leaves material porous, achieving densities of only around 71%.

VHP utilizes mechanical pressure to rearrange particles and force plastic flow, effectively closing internal pores.

This process drives density levels to over 96%, approaching a fully dense state that liquid casting often struggles to match due to shrinkage and gas entrapment.

The Role of the Vacuum Environment

The high vacuum (e.g., <0.1 Pa) is not merely for cleanliness; it is an active processing tool.

It removes adsorbed gases from the powder surfaces that would otherwise create voids or inclusions in a cast part.

Furthermore, it prevents the oxidation of the aluminum matrix and reinforcements during the heating cycle, ensuring that the interface between the matrix and the reinforcement remains clean and strong.

Understanding the Trade-offs

While VHP offers superior material properties, it is important to acknowledge the operational constraints compared to casting.

Geometric Limitations Casting allows for the production of complex, near-net-shape components. VHP is typically limited to simple geometries (billets or plates) that require subsequent machining.

Throughput and Cost VHP is a batch process that is generally slower and more capital-intensive per unit than continuous or bulk casting methods. It is a process chosen for performance, not high-volume economy.

Making the Right Choice for Your Goal

When selecting a manufacturing method for 2024Al/Gr/SiC composites, align your choice with the component's critical requirements.

- If your primary focus is maximum mechanical strength and thermal conductivity: Use Vacuum Hot Pressing. The mitigation of brittle carbides and high densification are non-negotiable for high-performance applications.

- If your primary focus is complex geometry without machining: Use Casting, but recognize that you will likely sacrifice material properties due to interface reactions and lower density.

Summary: Vacuum hot pressing is the definitive choice for critical applications where the material's internal structural integrity outweighs the need for complex geometric shaping.

Summary Table:

| Feature | Vacuum Hot Pressing (VHP) | Traditional Liquid Casting |

|---|---|---|

| Material State | Solid-state / Semi-solid | Liquid-state (Melted) |

| Interface Quality | No $Al_4C_3$ (brittle carbides) | High risk of brittle reactions |

| Densification | High (>96% density) | Lower (risk of shrinkage/voids) |

| Bonding Mechanism | Mechanical rupture of oxide films | Liquid wetting of reinforcements |

| Geometry | Simple billets/plates | Complex near-net shapes |

| Best For | High-performance integrity | High-volume, complex parts |

Elevate Your Material Performance with KINTEK

Are you struggling with brittle interfaces or low density in your composite manufacturing? KINTEK specializes in advanced thermal solutions designed to solve your most complex material challenges. Backed by expert R&D and precision manufacturing, we offer high-performance Vacuum Hot Pressing systems, Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to your specific research or production needs.

Don't compromise on structural integrity. Our vacuum systems ensure clean, dense, and high-strength metallurgical bonding for your target applications.

Contact our technical experts today to find the perfect customizable furnace solution for your lab.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of in-situ reaction/hot pressing for (Ti0.95Nb0.05)3SiC2 targets? Achieve High Density Coatings

- What is a vacuum hot press furnace and what are its primary uses? Unlock High-Performance Material Processing

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the characteristics of ultrahigh pressure sintering for ceramics? Achieve Dense, Fine-Grained Ceramics

- Why is a vacuum essential for TiAl/Ti6Al4V hot pressing? Unlock High-Performance Metallurgical Bonding

- How does the axial pressure applied by a vacuum hot pressing sintering furnace contribute to material densification?

- What is the purpose of applying vibration to the loaded graphite mold? Enhance TiAl-SiC Composite Sintering Performance

- What function does a vacuum hot press furnace serve in the densification of Nb-22.5Cr-5Si alloys? Achieve Full Density and Purity for Refractory Alloys