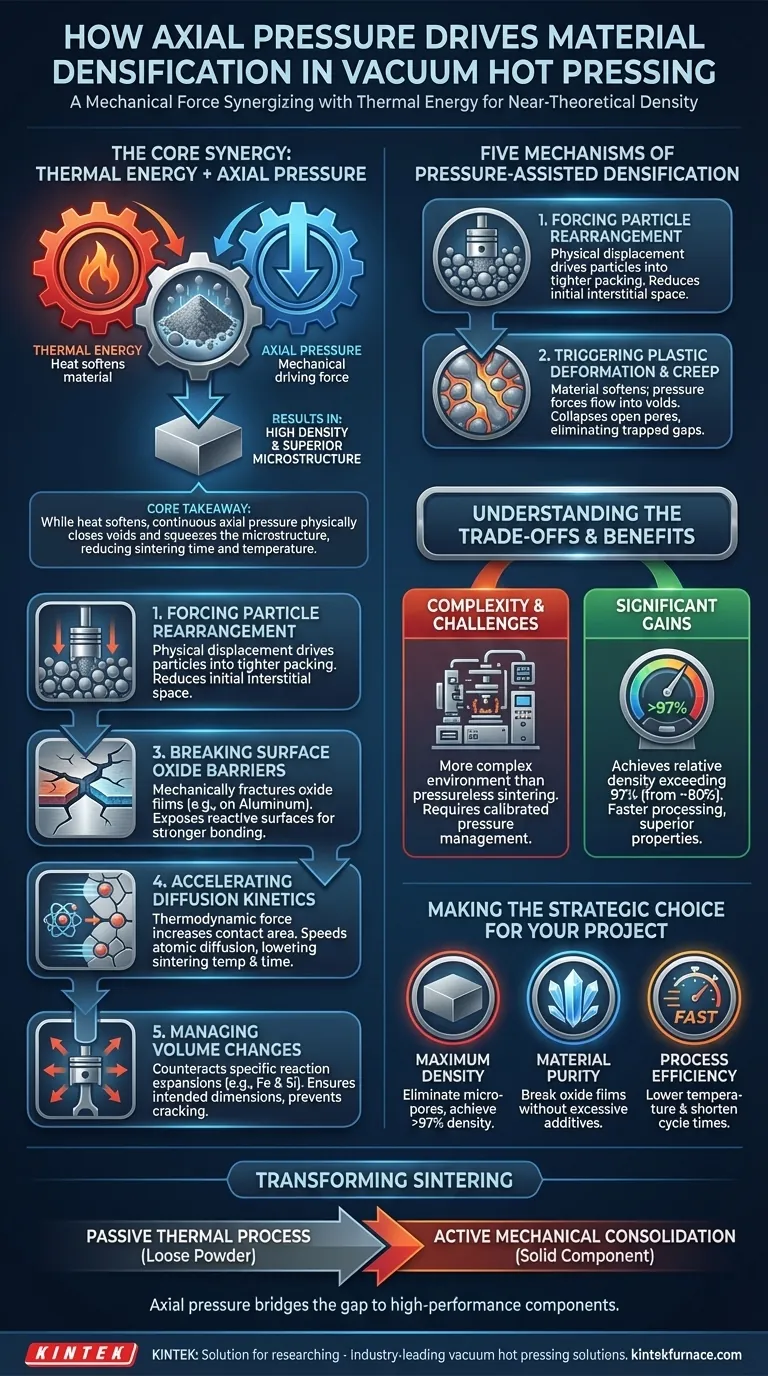

The axial pressure applied by a vacuum hot pressing furnace acts as a mechanical driving force that works synergistically with thermal energy to densify materials. By physically forcing powder particles together, this pressure accelerates particle rearrangement and triggers plastic deformation, allowing the material to achieve near-theoretical density levels that are often impossible with heat alone.

Core Takeaway While heat softens the material, it is the continuous axial pressure that physically closes voids and overcomes the natural resistance to bonding. This mechanical energy effectively "squeezes" the microstructure into a dense state, breaking down surface barriers and reducing the time and temperature required for successful sintering.

Mechanisms of Pressure-Assisted Densification

Forcing Particle Rearrangement

The primary contribution of axial pressure is the immediate physical displacement of powder particles. Unlike pressureless sintering, where particles settle naturally, the applied force mechanically drives particles into a tighter packing configuration.

This rearrangement reduces the volume of interstitial space between particles before bonding even begins. It provides the necessary initial contact required to start the densification process efficiently.

Triggering Plastic Deformation and Creep

As the temperature rises, the material softens; the applied pressure then forces the particles to undergo plastic deformation. This mechanism causes the material to flow into the remaining voids, effectively filling the gaps between particles.

This process, often described as plastic flow or creep, leads to the collapse of open pores. It ensures that voids are eliminated rather than simply trapped inside the material, which is a common issue in pressureless sintering.

Breaking Surface Oxide Barriers

A critical, often overlooked function of axial pressure is its ability to fracture surface layers. As described in the primary reference regarding aluminum alloys, the pressure effectively breaks oxide films that naturally form on particle surfaces.

These oxide films often act as barriers to diffusion. By mechanically rupturing them, the furnace exposes clean, reactive surfaces, allowing for direct particle-to-particle contact and stronger bonding.

Accelerating Diffusion Kinetics

Pressure provides an additional thermodynamic driving force that overcomes diffusion resistance. By forcing atoms closer together and increasing the contact area, the system facilitates faster atomic diffusion across grain boundaries.

This accelerated diffusion significantly reduces the sintering temperature and time required to reach full density. It allows for rapid consolidation, preventing the grain growth that often occurs during prolonged heating cycles.

Understanding the Trade-offs

Complexity vs. Density Gains

The addition of mechanical pressure creates a more complex processing environment compared to standard pressureless sintering. However, the trade-off yields significantly higher performance; for example, increasing relative density from ~80% to exceeding 97% in superhard materials.

Managing Volume Changes

The applied pressure must be carefully calibrated to counteract specific reactions. In certain synthesis reactions (such as Fe and Si), volume expansion occurs. The external axial pressure effectively counteracts this expansion, ensuring the final product maintains its intended dimensions and hardness rather than swelling or cracking.

Making the Right Choice for Your Project

The application of vacuum hot pressing is a strategic choice dependent on your material requirements.

- If your primary focus is Maximum Density: Rely on axial pressure to eliminate micro-pores and closed voids, achieving relative densities exceeding 97% and drastically reducing porosity.

- If your primary focus is Material Purity: Utilize the pressure to break oxide films on difficult alloys (like Aluminum), ensuring direct bonding without requiring excessive flux or additives.

- If your primary focus is Process Efficiency: Leverage the pressure-assisted mechanism to lower the required sintering temperature and shorten cycle times, preserving the microstructure from excessive heat exposure.

Ultimately, axial pressure transforms sintering from a passive thermal process into an active mechanical consolidation, bridging the gap between loose powder and a solid, high-performance component.

Summary Table:

| Mechanism | Role in Densification | Key Benefit |

|---|---|---|

| Particle Rearrangement | Physical displacement of powder | Eliminates initial interstitial gaps |

| Plastic Deformation | Material flow into remaining voids | Collapses open pores as material softens |

| Surface Film Rupture | Breaks oxide layers on particles | Exposes clean surfaces for direct bonding |

| Diffusion Kinetics | Increases contact area & atomic flow | Lowers required sintering time and temp |

| Volume Management | Counteracts synthesis expansion | Prevents cracking and maintains dimensions |

Maximize Material Density with KINTEK Expertise

Achieve near-theoretical density and superior microstructure for your most demanding applications. KINTEK provides industry-leading vacuum hot pressing solutions backed by expert R&D and precision manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our laboratory high-temperature furnaces are fully customizable to meet your unique sintering requirements.

Ready to transform your material performance? Contact KINTEK today to discuss your custom furnace needs.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a laboratory vacuum system essential for the SPS of LaFeO3? Ensure Phase Purity and Tooling Longevity

- What are the advantages of using hot press sintering equipment? Optimize SiC/Cu-Al2O3 Composite Performance

- What are the advantages of a high-pressure vacuum induction hot press furnace? Boost SiGe Thermoelectric Performance

- How are vacuum presses utilized in the aerospace and automotive industries? Enhance Performance with Lightweight Composites

- What function does a vacuum hot press furnace serve in the densification of Nb-22.5Cr-5Si alloys? Achieve Full Density and Purity for Refractory Alloys

- How does graphite felt function as an insulation material in FAST equipment? Boost Efficiency & Thermal Uniformity

- What are the main components of a vacuum hot press furnace? Unlock Precision Material Processing

- What are the advantages of using a vacuum hot pressing furnace compared to explosive cladding? Get Precision Results