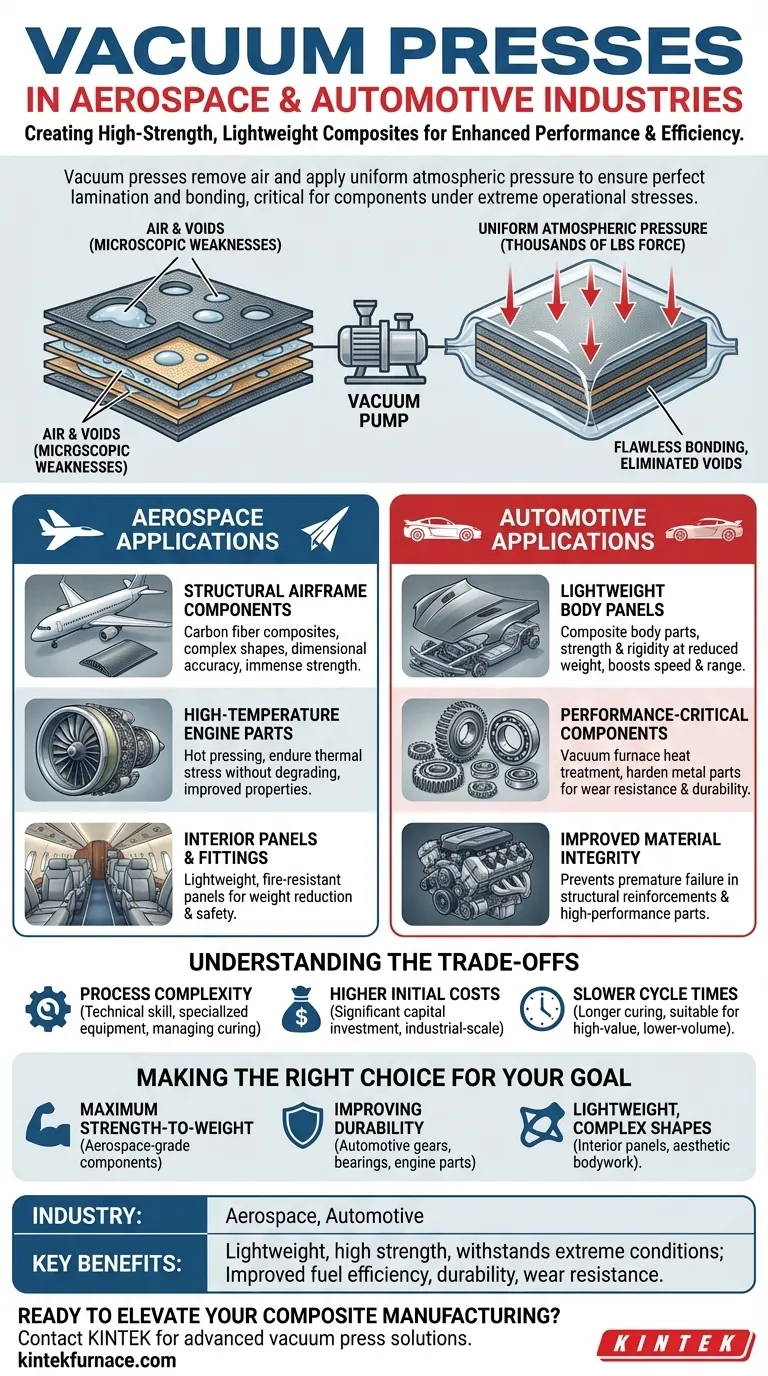

In short, vacuum presses are used in the aerospace and automotive industries to manufacture high-strength, lightweight composite parts. By removing air and applying uniform atmospheric pressure, these presses ensure perfect lamination and bonding of materials, which is critical for creating components that enhance performance, safety, and fuel efficiency.

The core function of a vacuum press is not merely to shape a part, but to guarantee its material integrity. In high-stakes industries like aerospace and automotive, this process eliminates microscopic weaknesses, ensuring components can withstand extreme operational stresses without failure.

The Core Principle: Why Vacuum is Essential

Using a vacuum is fundamental to creating flawless composite materials. The process addresses challenges that are simply insurmountable with conventional clamping or pressing methods alone.

Eliminating Air and Voids

Any air or volatile gas trapped between layers of composite material creates a void. These voids are microscopic weak points that can compromise the structural integrity of the entire component under stress, leading to delamination or fracture.

A vacuum pump removes all air from within the layup before and during the curing process, ensuring the resin flows completely and bonds every fiber without imperfections.

Ensuring Uniform Pressure

Once a vacuum is achieved inside the sealed bag, the external atmospheric pressure exerts a perfectly uniform force across the entire surface of the part. This consistent pressure is equivalent to thousands of pounds of clamping force, ensuring intimate contact between all layers.

This method is far superior to mechanical clamping, which can create uneven pressure points and lead to a weaker, less reliable final product.

Applications in Aerospace: Pushing the Limits of Performance

In aerospace, every gram of weight matters, and structural failure is not an option. Vacuum pressing is indispensable for manufacturing components that meet these extreme demands.

Structural Airframe Components

Key structural parts like wings, fuselage sections, and control surfaces are often made from carbon fiber composites. Vacuum hot pressing creates these large, complex shapes with the required dimensional accuracy and immense strength needed to withstand the forces of flight.

High-Temperature Engine Parts

Specialized hot pressing techniques allow for the creation of composite parts that can operate in the extreme high-temperature environments of jet engines. This process improves the material's mechanical properties, enabling it to endure thermal stress without degrading.

Interior Panels and Fittings

Beyond primary structures, vacuum presses are used for interior components like cabin walls, overhead bins, and galleys. This allows for the creation of strong, lightweight, and fire-resistant panels that contribute to overall weight reduction and safety.

Applications in Automotive: Driving Efficiency and Safety

The automotive industry uses vacuum processing to produce lightweight parts that improve fuel economy and performance, as well as to enhance the durability of critical mechanical components.

Lightweight Body Panels

High-performance vehicles and electric cars rely on lightweighting to boost speed and range. Vacuum-formed composite body panels, hoods, and chassis components provide the necessary strength and rigidity at a fraction of the weight of steel or aluminum.

Performance-Critical Components

The principles of vacuum technology extend to heat treatment. Vacuum furnaces are used to harden metal parts like gears, bearings, and engine components. This process improves wear resistance and durability, ensuring these parts can endure high-speed operation and heavy loads for longer.

Improved Material Integrity

For components subjected to constant vibration and stress, vacuum pressing ensures flawless material integrity. This prevents premature failure in everything from structural reinforcements to high-performance drivetrain parts.

Understanding the Trade-offs

While vacuum pressing is a powerful technology, it is not without its complexities. Understanding its limitations is key to its successful implementation.

Process Complexity

Achieving a perfect vacuum seal and managing the curing process requires significant technical skill and specialized equipment. The list of necessary hardware often includes specific pumps like rotary vane, diffusion, or roots pumps, each suited for different applications.

Higher Initial Costs

The equipment required for industrial-scale vacuum pressing, especially hot presses for aerospace, represents a significant capital investment compared to traditional metal fabrication tools.

Slower Cycle Times

Curing a composite part under vacuum can take several hours, which is considerably longer than stamping a metal part. This makes it better suited for high-value, lower-volume production rather than mass-market automotive manufacturing.

Making the Right Choice for Your Goal

The specific vacuum-based technique you employ should align directly with your end goal.

- If your primary focus is maximum strength-to-weight ratio for critical parts: Hot pressing is the ideal choice for creating aerospace-grade components that must perform under extreme conditions.

- If your primary focus is improving the durability of mechanical parts: Vacuum furnace heat treatments are essential for enhancing the hardness and wear resistance of automotive gears, bearings, and engine components.

- If your primary focus is creating lightweight, complex shapes for non-structural use: Standard vacuum bag molding is a versatile and effective method for parts like interior panels or aesthetic bodywork.

Ultimately, vacuum technology empowers engineers to build stronger, lighter, and more reliable components than ever before.

Summary Table:

| Industry | Key Applications | Benefits |

|---|---|---|

| Aerospace | Structural airframe components, engine parts, interior panels | Lightweight, high strength, withstands extreme conditions |

| Automotive | Lightweight body panels, gears, bearings, engine components | Improved fuel efficiency, durability, wear resistance |

Ready to elevate your composite manufacturing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced vacuum press solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our high-temperature furnace solutions can enhance your performance and efficiency!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is a vacuum press and why is it important in modern manufacturing? Unlock Flawless Bonding and Precision

- What factors should be considered when choosing between hot pressing and cold compacting and sintering? Optimize Your Material Manufacturing

- How does automation enhance the hot pressing process? Boost Precision, Efficiency, and Quality

- How does hot pressing compare to hot isostatic pressing (HIP)? Choose the Right Process for Your Materials

- How does hot pressing differ from ordinary cold pressing and sintering? Unlock Superior Material Performance