The primary advantage of using hot deep drawing equipment equipped with a blank holder for TC4 titanium alloy is the effective elimination of wrinkling and structural instability. By applying a constraining force to the edges of the sheet, this equipment restricts material flow into the die, ensuring the material remains stable throughout the forming process.

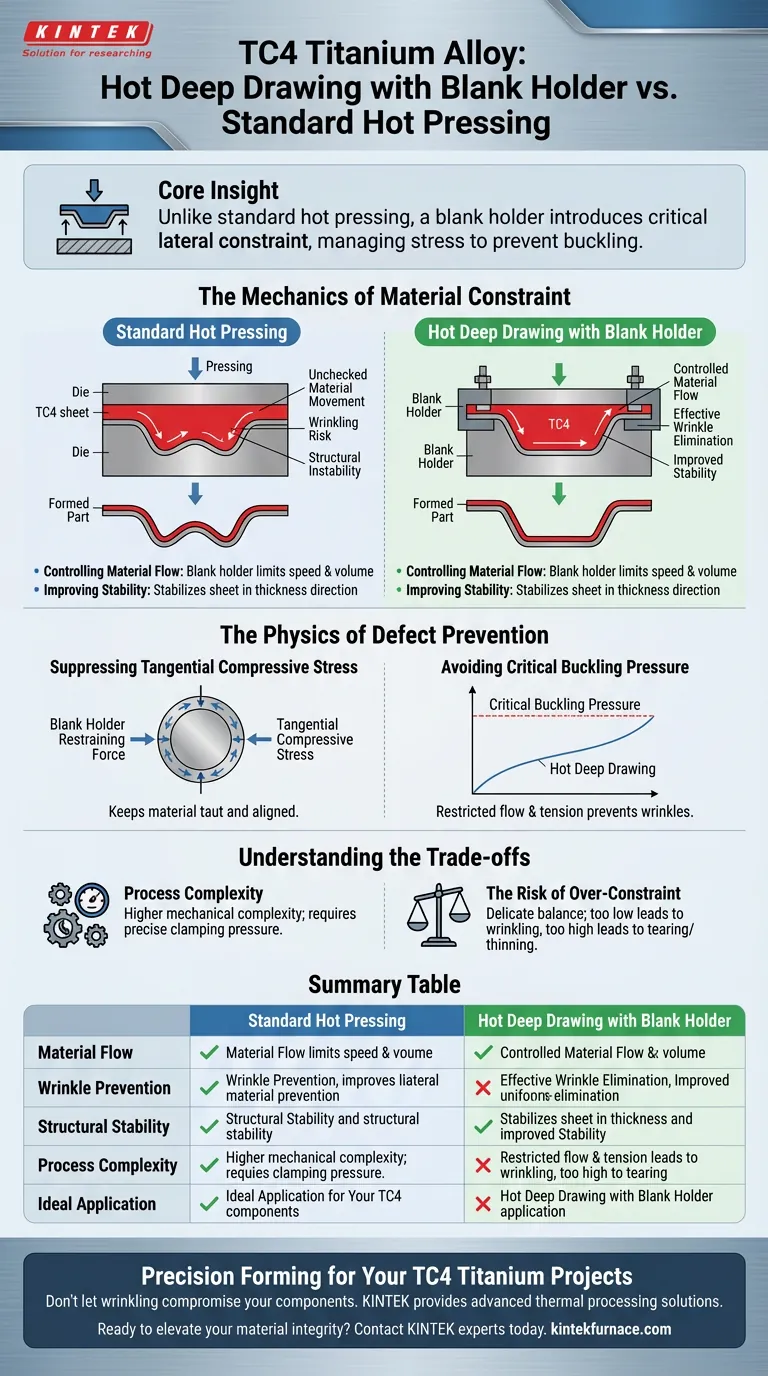

Core Insight: Unlike standard hot pressing, which may allow unchecked material movement, a blank holder introduces a critical lateral constraint. This constraint actively manages stress within the sheet to prevent it from buckling under the pressure of deformation.

The Mechanics of Material Constraint

The fundamental difference lies in how the equipment handles the edges of the TC4 sheet during the forming cycle.

Controlling Material Flow

Standard hot pressing often relies on the die shape alone to form the part.

In contrast, a blank holder clamps the edges of the alloy sheet, applying a specific constraining force. This effectively limits the speed and volume of material flowing into the die cavity.

Improving Stability in the Thickness Direction

Thin-walled structures are notoriously difficult to form because they lack inherent rigidity.

The lateral constraint provided by the blank holder stabilizes the sheet in the thickness direction. This ensures the material remains uniform and does not deviate or warp as it is drawn into the mold.

The Physics of Defect Prevention

To understand why the blank holder is superior for quality, you must look at the stress forces acting on the titanium alloy.

Suppressing Tangential Compressive Stress

As the material is drawn, it naturally experiences tangential compressive stress.

If left unchecked, this stress causes the material to fold over itself. The blank holder's restraining force suppresses this stress, keeping the material taut and aligned.

Avoiding Critical Buckling Pressure

Wrinkling is essentially a failure of stability; it happens when internal stress hits a specific tipping point known as "critical buckling pressure."

By restricting flow and maintaining tension, the blank holder ensures the material never reaches this critical pressure threshold. The result is a smooth component free of the wrinkles that plague standard hot pressing methods.

Understanding the Trade-offs

While the blank holder offers superior part quality, it introduces variables that must be managed carefully.

Process Complexity

Adding a blank holder increases the mechanical complexity of the operation compared to standard hot pressing.

You are no longer just managing temperature and press force; you must also precisely control the clamping pressure on the sheet edges.

The Risk of Over-Constraint

There is a delicate balance required when applying constraining force.

If the force is too low, wrinkling will occur; if the force is too high, the material may not flow at all, leading to tearing or thinning rather than forming.

Making the Right Choice for Your Goal

The decision between standard hot pressing and deep drawing with a blank holder depends on your specific quality requirements.

- If your primary focus is producing thin-walled structures: You must use a blank holder to prevent the wrinkling and instability inherent to thin TC4 sheets.

- If your primary focus is simple, thick-walled geometries: Standard hot pressing may be sufficient, provided the material thickness offers enough inherent stability to resist buckling.

For high-precision TC4 titanium components, the blank holder is not just an accessory; it is a necessity for structural integrity.

Summary Table:

| Feature | Standard Hot Pressing | Hot Deep Drawing with Blank Holder |

|---|---|---|

| Material Flow | Unchecked/Die-dependent | Controlled by edge clamping |

| Wrinkle Prevention | Low (risk of buckling) | High (suppresses compressive stress) |

| Structural Stability | Low in thin-walled parts | High (stabilized thickness direction) |

| Process Complexity | Low | Higher (requires pressure calibration) |

| Ideal Application | Simple, thick-walled parts | Precision thin-walled TC4 components |

Precision Forming for Your TC4 Titanium Projects

Don't let wrinkling and structural instability compromise your high-performance components. KINTEK provides industry-leading thermal processing solutions designed to handle the complexities of advanced materials. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique production or research needs.

Ready to elevate your material integrity? Contact our experts today to find the perfect customizable solution for your laboratory or manufacturing facility.

Visual Guide

References

- Tao Zhang, Xiaochuan Liu. Deformation Control of TC4 Titanium Alloy in Thin-Walled Hyperbolic Structures During Hot Forming Processes. DOI: 10.3390/ma17246146

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What advantages does a vacuum press offer in material processing? Achieve Superior Density and Purity

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- How do you maintain a heat press machine? A Proactive Guide to Consistent Prints & Longevity

- Why is a vacuum hot press furnace preferred over a conventional high-temperature sintering furnace for preparing ZrC-SiC composites? Achieve Superior Density and Purity

- Why is maintaining a high vacuum environment essential during the hot pressing of aluminum-based laminated composites? Ensure Superior Bonding and Density

- How does an industrial-grade hot press sintering system benefit Al2O3/TiC/SiC(w) ceramics? Enhanced Material Density

- How do vacuum and argon affect Ag-Ti2SnC composites? Optimize Sintering with Industrial Hot-Pressing Furnaces

- How do pressure parameters in a vacuum hot press influence stainless steel? Master High-Performance Densification