Maintaining a high vacuum environment during the hot pressing of aluminum-based laminated composites is not merely a precaution; it is a fundamental requirement for achieving structural integrity.

Because aluminum and its alloying elements (such as titanium or magnesium) are highly reactive, a vacuum level of approximately 1 x 10^-2 Pa is necessary to prevent the immediate formation of oxide layers that inhibit bonding. Furthermore, the vacuum actively removes trapped gases between the laminate layers, ensuring the material achieves high density and uniform strength.

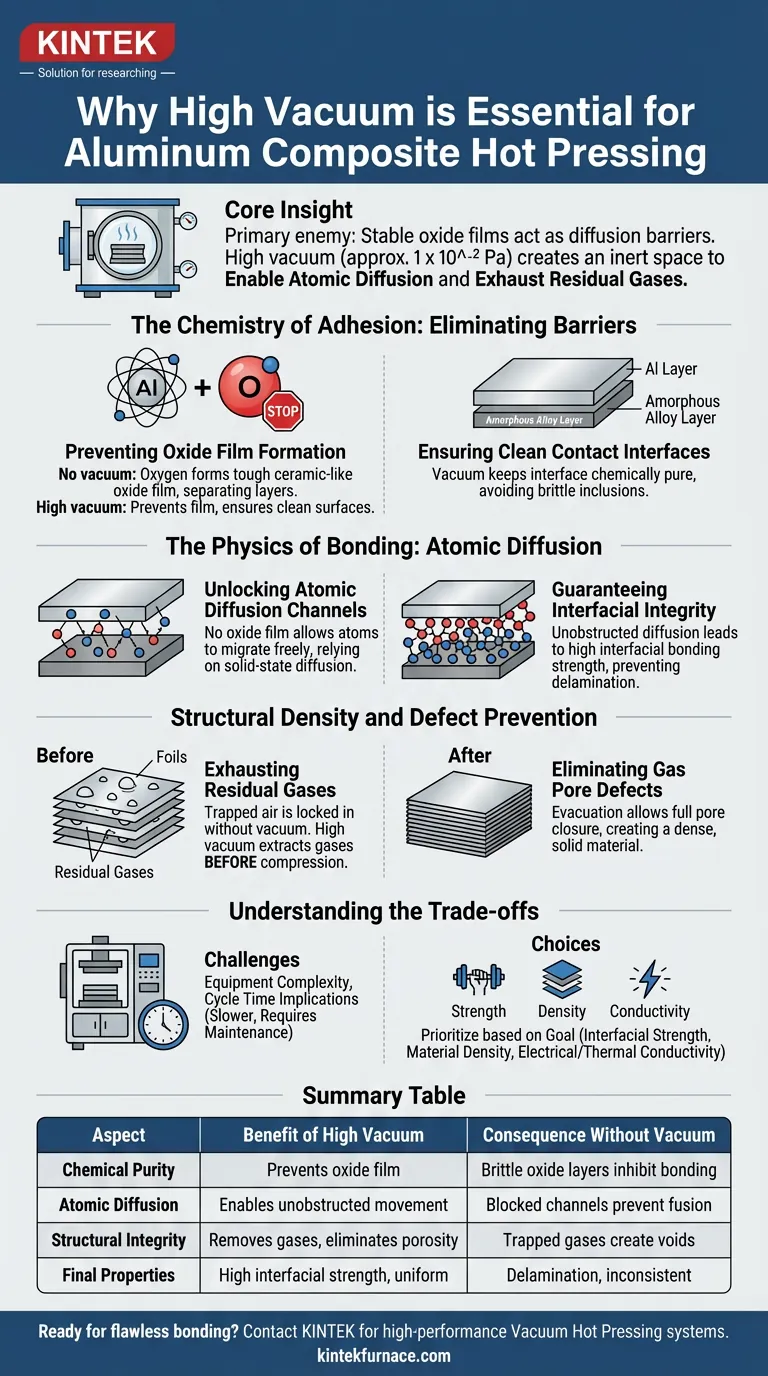

Core Insight

The primary enemy of aluminum hot pressing is the formation of stable oxide films that act as a diffusion barrier. A high vacuum environment serves a dual purpose: it creates a chemically inert space to enable atomic diffusion across layer interfaces and provides the pressure differential needed to exhaust residual gases, preventing porosity defects.

The Chemistry of Adhesion: Eliminating Barriers

Preventing Oxide Film Formation

Aluminum is well known for its rapid oxidation. At the elevated temperatures required for hot pressing, this reactivity increases significantly.

Without a high vacuum (specifically around 1 x 10^-2 Pa), oxygen reacts with the aluminum foil surfaces to form a tough, ceramic-like oxide film. This film physically separates the layers, making bonding impossible regardless of the pressure applied.

Ensuring Clean Contact Interfaces

For a composite to act as a single material, the interface between the layers must be chemically pure.

The vacuum environment ensures that the contact interface between amorphous alloy layers and aluminum layers remains clean. By avoiding the creation of brittle oxide inclusions, the process preserves the intrinsic strength of the raw materials.

The Physics of Bonding: Atomic Diffusion

Unlocking Atomic Diffusion Channels

Bonding in laminated composites relies on solid-state diffusion—the movement of atoms from one layer into the crystal lattice of the adjacent layer.

Oxide films block these "elemental diffusion channels." By maintaining a high vacuum, you remove this blockage, allowing atoms to migrate freely across the boundary.

Guaranteeing Interfacial Integrity

The ultimate strength of the composite is defined by the quality of the bond between layers.

When atomic diffusion is unobstructed, the layers fuse at a molecular level. This results in high interfacial bonding strength, preventing delamination under stress.

Structural Density and Defect Prevention

Exhausting Residual Gases

When stacking multiple sheets of foil, pockets of air and other gases are inevitably trapped between the layers.

If the stack is compressed without a vacuum, these gases are locked inside. A high vacuum environment extracts these residual gases before the material is fully compressed.

Eliminating Gas Pore Defects

Trapped gases lead to porosity (voids) within the final composite.

By evacuating these gases, the vacuum allows for full pore closure during the pressing phase. This ensures the final material is dense, solid, and free of internal gas pore defects that would act as stress concentrators.

Understanding the Trade-offs

While a high vacuum is essential for quality, it introduces specific operational challenges that must be managed.

Equipment Complexity and Maintenance

Achieving and maintaining 1 x 10^-2 Pa requires sophisticated sealing and pumping systems. Leaks, however microscopic, can compromise the entire batch by introducing oxygen at critical temperatures.

Cycle Time Implications

Creating a high vacuum environment adds time to the production cycle. Operators must balance the time required to pump down the chamber against production throughput goals, though rushing this step invariably leads to oxidation and poor bonding.

Making the Right Choice for Your Goal

The level of vacuum control you exert should align with the specific mechanical properties you need to maximize in your aluminum composite.

- If your primary focus is Interfacial Strength: Prioritize the depth of the vacuum (reaching 1 x 10^-2 Pa or better) to ensure zero oxidation interferes with atomic diffusion.

- If your primary focus is Material Density: Prioritize the timing of the vacuum application, ensuring gases are fully exhausted before maximum hydraulic pressure is applied to the stack.

- If your primary focus is Electrical/Thermal Conductivity: Ensure the vacuum system is free of contaminants to maintain the purity of the interface, as oxides act as insulators.

The vacuum environment is the invisible tool that transforms a stack of loose foils into a unified, high-performance composite.

Summary Table:

| Aspect | Benefit of High Vacuum | Consequence Without Vacuum |

|---|---|---|

| Chemical Purity | Prevents oxide film formation on aluminum surfaces. | Brittle oxide layers inhibit bonding, leading to weak interfaces. |

| Atomic Diffusion | Enables unobstructed atomic movement across layer boundaries. | Blocked diffusion channels prevent molecular-level fusion. |

| Structural Integrity | Removes trapped gases to eliminate porosity and ensure high density. | Trapped gases create voids, acting as stress concentrators and reducing strength. |

| Final Properties | Achieves high interfacial strength and uniform material properties. | Results in delamination and inconsistent performance under stress. |

Ready to achieve flawless bonding in your aluminum composites?

Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Hot Pressing systems, designed to create and maintain the precise, high-vacuum environment essential for your success. Our systems are customizable to meet your unique material and production needs.

Contact us today to discuss your project and discover how KINTEK can help you unlock superior material performance.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the function of the low-pressure debinding stage in a vacuum hot press? Ensure SiC Fiber Alignment & Integrity

- How does Vacuum Hot Press equipment contribute to the energy and power generation sector? Boost Efficiency and Durability

- How to maintain a vacuum machine? Ensure long-term reliability and peak performance

- What role does a hot-press sintering furnace play in Y2O3-YAM composite ceramics? Achieve 100% Density & Control Grains

- How does temperature control precision of a vacuum hot press affect SiC fiber/TB8 matrix? Optimize Interface Quality

- How does the pressure-assisted mechanism in a Vacuum Hot Press Furnace improve YAG ceramics? Unlock Optical Clarity

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- Why is a medium frequency induction heating system utilized in the manufacture of diamond drills via vacuum hot pressing? For Superior Speed and Durability