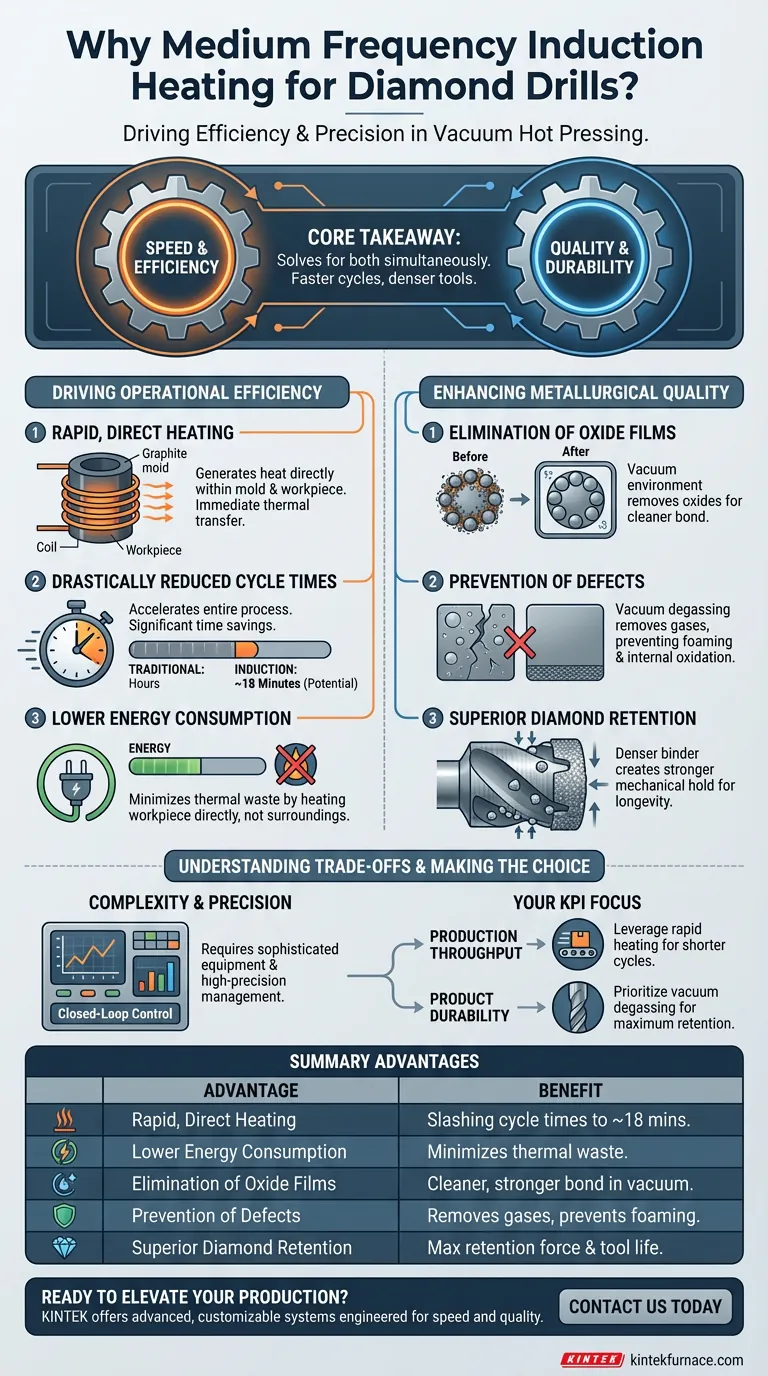

Medium frequency induction heating acts as the primary driver for efficiency and precision in the manufacturing of diamond drills via vacuum hot pressing. It is utilized because it allows for the rapid, direct heating of graphite molds and workpieces, enabling a manufacturing cycle that is significantly faster and more energy-efficient than traditional methods.

The Core Takeaway: The value of this system lies in its ability to simultaneously solve for speed and quality. It drastically cuts sintering time while utilizing a vacuum environment to eliminate oxides, resulting in a denser, more durable diamond tool.

Driving Operational Efficiency

Rapid, Direct Heating

The defining characteristic of medium frequency induction is its ability to generate heat directly within the graphite mold and workpiece. Unlike methods that rely on external radiation, this allows for immediate thermal transfer.

Drastically Reduced Cycle Times

This direct heating method accelerates the entire manufacturing process. Sintering times are significantly shortened, with the potential to complete a piece in as little as 18 minutes.

Lower Energy Consumption

By heating the workpiece directly rather than heating the surrounding element and air, the system minimizes thermal waste. This results in substantially reduced energy consumption compared to traditional sintering processes.

Enhancing Metallurgical Quality

Elimination of Oxide Films

Vacuum hot pressing creates a controlled environment that standard atmospheric equipment cannot match. It utilizes a reducing atmosphere to effectively eliminate oxide films on metal particles.

Prevention of Defects

The integration of vacuum degassing removes adsorbed gases from the powder surface before sintering occurs. This proactive step prevents common structural defects, such as product foaming and internal oxidation.

Superior Diamond Retention

The removal of impurities leads to a significantly improved density of the metal binder. A denser binder creates a stronger mechanical hold (retention force) on the diamond, which is critical for the drill's performance and longevity.

Understanding the Trade-offs

Equipment Complexity vs. Simplicity

While effective, this process requires sophisticated vacuum hot pressing equipment rather than standard atmospheric furnaces. It demands the integration of three distinct functions: vacuum degassing, atmosphere treatment, and hot pressing.

The Necessity of Precision Control

Because induction heating is so rapid, it cannot be managed manually or by simple thermostats. It requires a closed-loop temperature control system to achieve high-precision management and prevent overheating.

Making the Right Choice for Your Production

If you are evaluating whether to transition to medium frequency induction vacuum hot pressing, consider your primary manufacturing KPIs:

- If your primary focus is Production Throughput: Leverage the rapid heating capabilities to reduce sintering cycles to approximately 18 minutes per piece.

- If your primary focus is Product Durability: Prioritize the vacuum degassing feature to increase metal binder density and maximize diamond retention force.

This technology bridges the gap between high-speed production and high-performance metallurgy.

Summary Table:

| Advantage | Benefit |

|---|---|

| Rapid, Direct Heating | Heats graphite molds and workpieces directly, slashing cycle times to ~18 minutes. |

| Lower Energy Consumption | Minimizes thermal waste by heating the workpiece, not the surrounding air. |

| Elimination of Oxide Films | Vacuum environment removes oxides for a cleaner, stronger bond. |

| Prevention of Defects | Vacuum degassing removes gases to prevent foaming and internal oxidation. |

| Superior Diamond Retention | Creates a denser metal binder for maximum diamond retention force and tool life. |

Ready to elevate your diamond tool production with precision and speed?

Backed by expert R&D and manufacturing, KINTEK offers advanced medium frequency induction vacuum hot pressing systems, all customizable for your unique needs. Our systems are engineered to deliver the rapid heating and superior metallurgical quality detailed above, directly impacting your production throughput and product durability.

Contact us today to discuss how a KINTEK solution can transform your manufacturing process.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the unique advantages of Spark Plasma Sintering (SPS)? Unlock Ultrafine Carbide Strength

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- What is the principle of hot pressing in manufacturing? Achieve High-Density Components with Precision

- What role does a Spark Plasma Sintering (SPS) system play in the preparation of Al0.3CoCrFeNiMo0.75 bulk materials?

- What is the core function of a flat tablet press in CSP? Achieve High-Pressure Densification for CaF2 Ceramics

- What is the core advantage of using a Hot Pressing Sintering (HPS) furnace? Enhance SiC/YAG Ceramic Density & Strength

- What capabilities do vacuum hot press furnaces offer for material manufacturing and processing? Unlock High-Density, Pure Materials

- What is the process of hot pressing? A Guide to Achieving Superior Material Density