At its core, a vacuum hot press furnace is a highly specialized tool that combines three critical manufacturing variables: high temperature, high mechanical pressure, and a controlled vacuum atmosphere. This unique combination enables the fabrication and processing of advanced materials, like high-purity ceramics and alloys, by simultaneously heating and compressing them in an environment free of reactive gases. This process results in exceptionally dense, pure components with tailored material properties that are often impossible to achieve with other methods.

The true capability of a vacuum hot press furnace lies in its synergistic control. By precisely manipulating heat, force, and atmosphere at the same time, it allows you to overcome the fundamental limitations of conventional furnaces, enabling the creation of fully dense, contamination-free advanced materials.

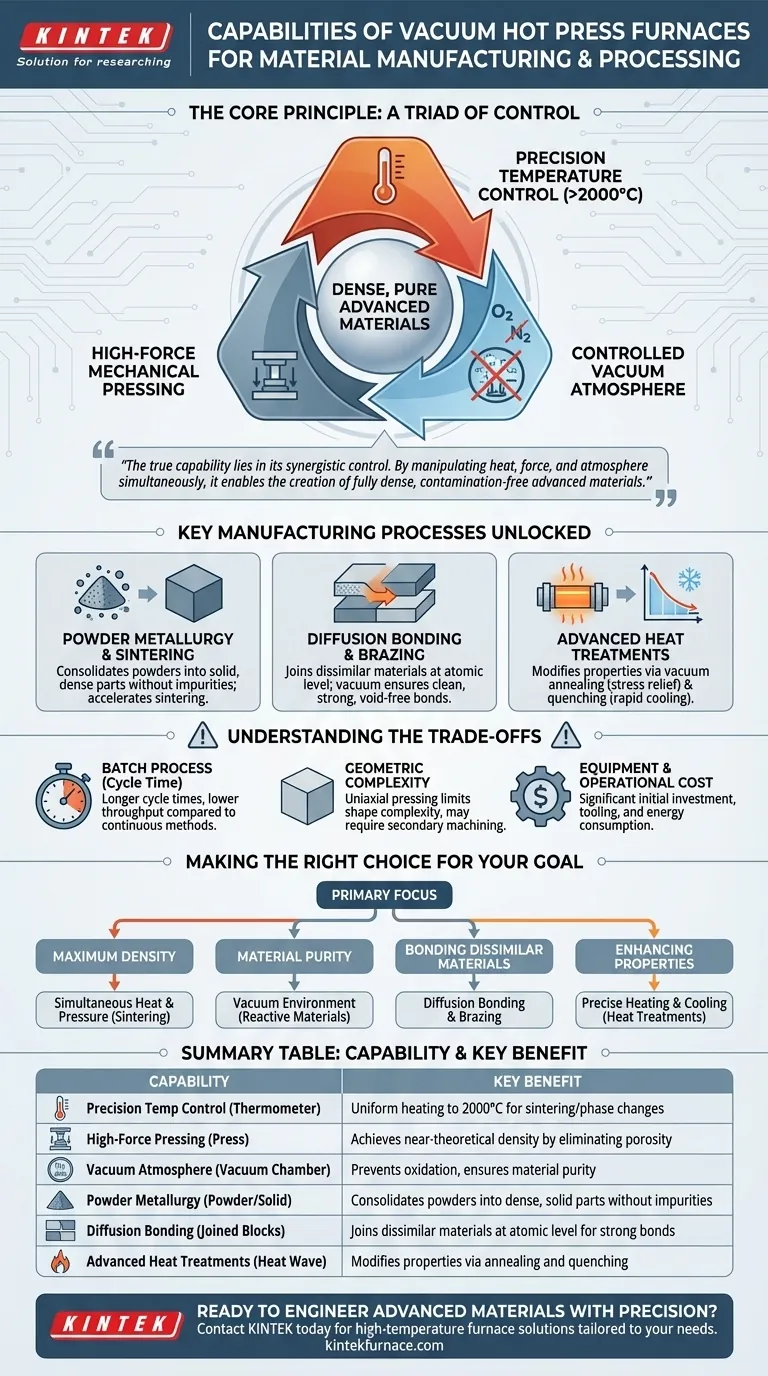

The Core Principle: A Triad of Control

The power of this technology comes from its ability to independently and simultaneously manage three physical parameters. Understanding how each contributes is key to grasping its full potential.

Precision Temperature Control

A vacuum hot press furnace provides uniform, highly controllable heating to temperatures often exceeding 2000°C.

This thermal energy is essential for initiating processes like sintering, diffusion, and phase changes within the material.

High-Force Mechanical Pressing

While being heated, the material is subjected to significant mechanical force, often from hydraulic rams.

This pressure physically closes the voids and porosity within the material, promoting densification and strong atomic bonds. It is the key to achieving near-theoretical density.

The Critical Role of the Vacuum

Creating a vacuum removes atmospheric gases like oxygen and nitrogen from the processing chamber.

This prevents oxidation, decarburization, and other unwanted chemical reactions that can degrade material properties at high temperatures. It also helps remove trapped gases from the material itself, ensuring a purer, less porous final product.

Key Manufacturing Processes Unlocked

The precise control over heat, pressure, and atmosphere unlocks several advanced manufacturing techniques that are critical for modern industries.

Powder Metallurgy and Sintering

This is the primary application. The furnace consolidates powders into a solid, dense part without the need for binders or other additives that can introduce impurities.

The combination of pressure and heat accelerates the sintering process, where powder grains bond and diffuse into one another, creating a fully dense component.

Diffusion Bonding and Brazing

The furnace can join dissimilar materials together at an atomic level through diffusion bonding, a process where pressure and heat cause atoms to migrate across the interface.

It is also ideal for vacuum brazing, where a filler metal is used to join components. The vacuum ensures a clean, strong, and void-free bond without oxidizing the base materials.

Advanced Heat Treatments

The furnace enables specialized heat treatments to modify material properties. Vacuum annealing can be used to relieve internal stresses in components like optical fibers, improving their performance.

Vacuum quenching, or rapid cooling under controlled conditions, can be used to lock in specific microstructures and achieve desired hardness or magnetic properties in alloys.

Understanding the Trade-offs

While incredibly powerful, vacuum hot press technology is not a universal solution. Understanding its limitations is crucial for proper application.

Cycle Time and Throughput

Vacuum hot pressing is a batch process, not a continuous one. The time required to pump down the vacuum, heat the material, apply pressure, and cool the system results in longer cycle times compared to other methods like atmospheric sintering.

This makes it less suitable for high-volume, low-cost manufacturing and better suited for high-value, performance-critical components.

Geometric Complexity

The process typically relies on uniaxial pressing, meaning force is applied along a single axis within a rigid die set.

This can limit the complexity of the shapes that can be produced directly. Complex geometries may require secondary machining operations after pressing.

Equipment and Operational Cost

Vacuum hot press furnaces are sophisticated, high-energy systems. Their initial acquisition cost, along with the expense of tooling, maintenance, and energy consumption, is significant.

Making the Right Choice for Your Goal

To determine if this technology fits your needs, align its core capabilities with your primary manufacturing objective.

- If your primary focus is achieving maximum material density: The simultaneous application of heat and pressure is the most effective method for eliminating porosity in powdered materials.

- If your primary focus is material purity and preventing reactions: The vacuum environment is non-negotiable for processing oxygen-sensitive materials like reactive metals, advanced ceramics, or high-purity alloys.

- If your primary focus is bonding dissimilar or difficult-to-weld materials: The control offered by vacuum diffusion bonding and brazing creates joints of unparalleled strength and cleanliness.

- If your primary focus is enhancing specific material properties: The furnace's precise control over heating and cooling cycles is ideal for specialized annealing and quenching treatments.

Ultimately, a vacuum hot press furnace provides the definitive control needed to engineer materials at a fundamental level.

Summary Table:

| Capability | Key Benefit |

|---|---|

| Precision Temperature Control | Enables uniform heating up to 2000°C for sintering and phase changes |

| High-Force Mechanical Pressing | Achieves near-theoretical density by eliminating porosity |

| Vacuum Atmosphere | Prevents oxidation and ensures material purity |

| Powder Metallurgy | Consolidates powders into dense, solid parts without impurities |

| Diffusion Bonding | Joins dissimilar materials at atomic level for strong bonds |

| Advanced Heat Treatments | Modifies properties via annealing and quenching in controlled environments |

Ready to engineer advanced materials with precision? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're focused on achieving maximum density, ensuring material purity, or bonding dissimilar materials, our vacuum hot press furnaces can help you overcome limitations and create contamination-free components. Contact us today to discuss how we can tailor a solution for your material processing goals!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the process of hot pressing? A Guide to Achieving Superior Material Density

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What materials can be densified using a vacuum press and what are their applications? Unlock High-Performance Material Densification

- How does a vacuum or protective atmosphere reduce oxidation in molten metals? Prevent Oxide Inclusions for Stronger Metals

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure