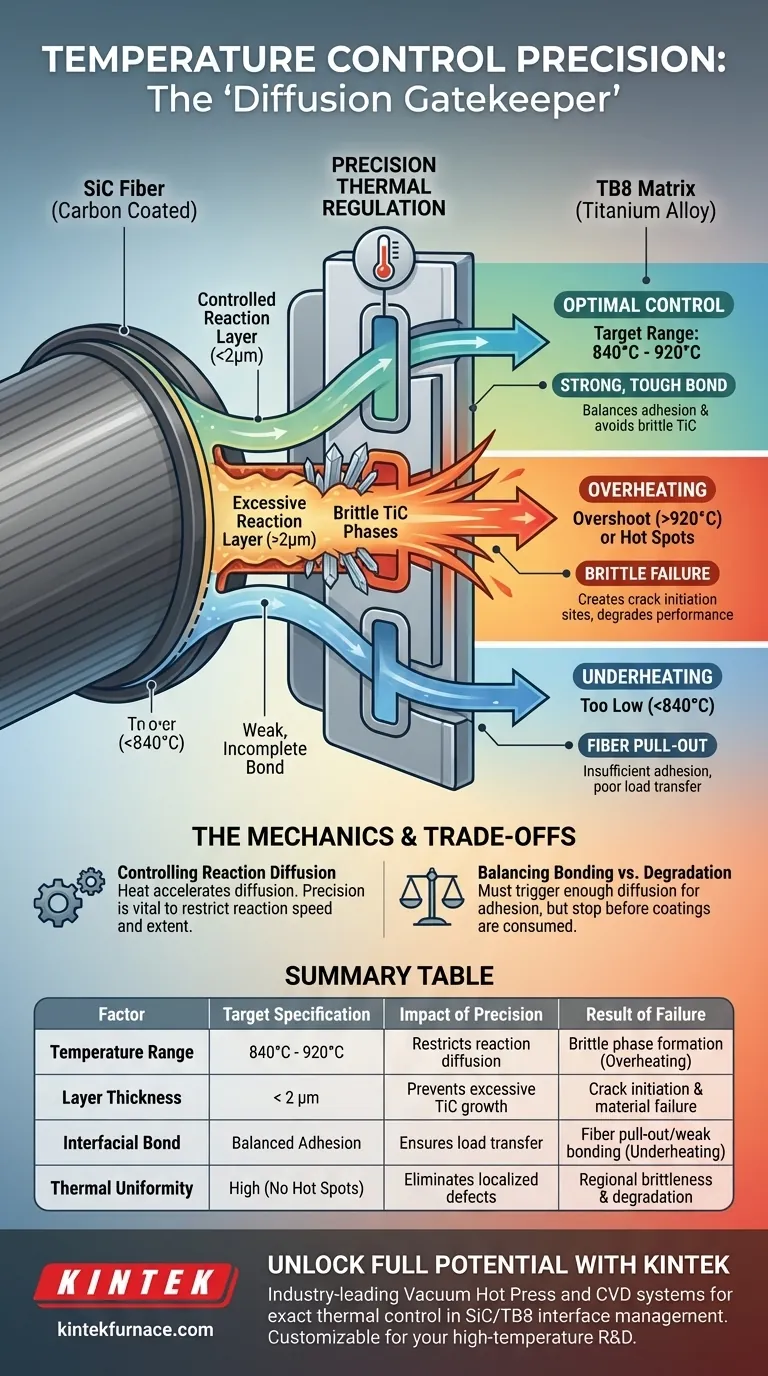

Temperature control precision is the single most critical variable determining the mechanical integrity of the interface between SiC fibers and the TB8 matrix. High-precision thermal regulation, specifically within the 840-920°C range, restricts the reaction diffusion between the fiber's carbon coating and the titanium matrix. This control ensures the interface reaction layer remains below 2 μm, preventing the formation of excessive, brittle titanium carbide (TiC) phases that degrade structural performance.

Core Takeaway Precision thermal regulation acts as a "diffusion gatekeeper," allowing just enough chemical interaction to bond the materials while strictly limiting the growth of brittle reaction layers that lead to premature material failure.

The Mechanics of Interface Formation

Controlling Reaction Diffusion

The interface layer in these composites is formed through reaction diffusion. This occurs when the carbon (C) coating on the SiC fibers interacts chemically with the titanium in the TB8 matrix.

Because diffusion rates are exponentially sensitive to heat, even minor temperature fluctuations can drastically alter the speed and extent of this reaction.

The Ideal Thickness Threshold

To maintain material performance, the reaction layer thickness must be strictly controlled. The target is generally less than 2 μm.

Achieving this requires the vacuum hot press to hold temperatures within a tight window, typically 840-920°C. This specific range provides enough energy for bonding without driving the reaction too far.

Consequences of Thermal Instability

The Danger of Overheating

If the temperature control lacks precision and overshoots the target window, the diffusion process accelerates aggressively.

This leads to the formation of an excessively thick interface layer. In the context of SiC/TB8, this creates a heavy concentration of Titanium Carbide (TiC).

Brittle Phase Failure

A thick TiC layer is detrimental because it is inherently brittle.

Instead of transferring loads effectively between the matrix and the fiber, a thick TiC layer acts as a defect. It becomes a site for crack initiation, significantly reducing the composite's overall strength and ductility.

The Risk of Underheating

While the primary reference focuses on limiting thickness, supplementary data suggests that precision is equally vital to prevent underheating.

If the temperature is too low, the necessary displacement reaction may not proceed at all. This results in weak interfacial bonding, causing the fibers to pull out of the matrix under stress rather than reinforcing it.

Understanding the Trade-offs

Balancing Bonding vs. Degradation

There is a fine line between a "strong bond" and a "degraded fiber." You need the reaction to occur to create adhesion, but you must stop it before it consumes the protective coatings.

Precision vs. Equipment Cost

Achieving the necessary thermal uniformity often requires advanced vacuum hot press technology.

Standard furnaces with high thermal gradients may achieve the average temperature but create localized hot spots. These spots can create regions of brittle failure even if the average readout seems correct.

Making the Right Choice for Your Goal

To optimize the performance of SiC fiber-reinforced TB8 composites, your thermal strategy must be aligned with specific material outcomes:

- If your primary focus is fracture toughness: Target the lower end of the temperature window (closer to 840°C) to keep the reaction layer as thin as possible, minimizing brittle TiC formation.

- If your primary focus is interfacial shear strength: Ensure the temperature is high enough to trigger sufficient diffusion for bonding, but strictly cap the dwell time to prevent layer overgrowth (>2 μm).

Mastery of temperature precision is not just a process variable; it is the prerequisite for unlocking the full structural potential of metal matrix composites.

Summary Table:

| Factor | Target Specification | Impact of Precision | Result of Failure |

|---|---|---|---|

| Temperature Range | 840°C - 920°C | Restricts reaction diffusion | Brittle phase formation (Overheating) |

| Layer Thickness | < 2 μm | Prevents excessive TiC growth | Crack initiation & material failure |

| Interfacial Bond | Balanced Adhesion | Ensures load transfer | Fiber pull-out/weak bonding (Underheating) |

| Thermal Uniformity | High (No Hot Spots) | Eliminates localized defects | Regional brittleness & degradation |

Unlock the Full Potential of Your High-Performance Composites

Precision is the difference between a high-strength composite and a brittle failure. KINTEK provides industry-leading Vacuum Hot Press and CVD systems designed to give you the exact thermal control needed for delicate SiC/TB8 interface management.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet the unique high-temperature demands of your lab. Whether you need to minimize reaction layers or maximize shear strength, KINTEK has the expertise to help you succeed.

Ready to elevate your material integrity?

Contact KINTEK Experts Today

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is the core role of a Vacuum Hot Pressing (VHP) furnace? Achieve Peak Infrared Transmittance in ZnS Ceramics

- Why is precise temperature control critical in AlMgTi composite preparation? Mastering the 437°C Eutectic Barrier

- How does a vacuum hot press furnace contribute to the densification of SiC/Al composites? Achieve Near-Zero Porosity

- What is the role of the vacuum environment in SiC/ZTA sintering? Enhance Densification & Material Purity

- What is the key principle of a hot press sintering furnace? Achieve Superior Densification for High-Performance Materials

- What are some applications of hot pressing in the field of ceramics? Unlock Superior Performance in Advanced Ceramics

- Can you use a heat press for laminating? A Practical Guide for DIY and Crafting

- What processes are used for vacuum pressing and preforming of fabrics and fiber materials? Master Uniform Consolidation for Composites