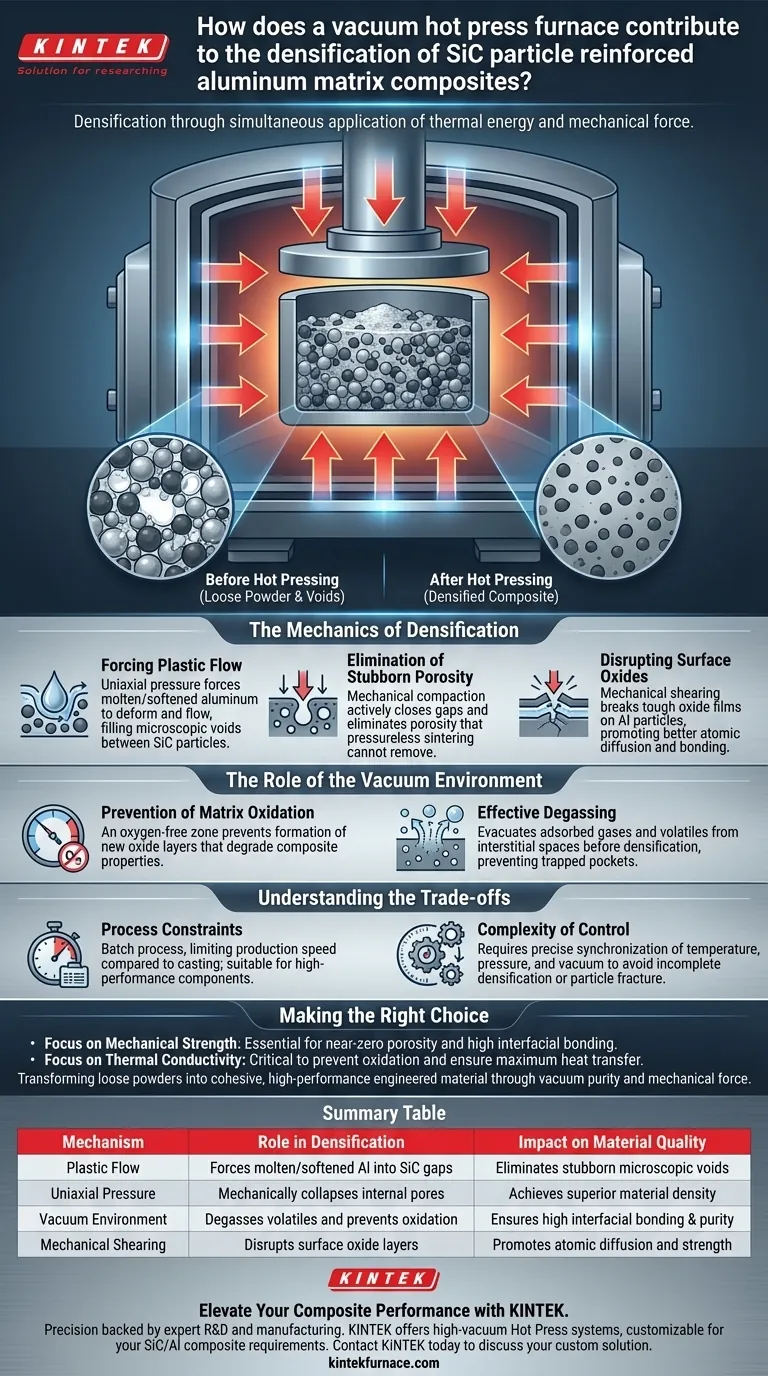

A vacuum hot press furnace achieves densification through the simultaneous application of thermal energy and mechanical force. By applying external pressure while the aluminum matrix is in a solid-liquid or molten state, the furnace forces the metal to undergo plastic flow. This deformation physically fills the voids between Silicon Carbide (SiC) particles, eliminating porosity that traditional pressureless sintering cannot remove.

The core advantage lies in the synergy of force and environment: while heat softens the matrix, mechanical pressure drives the aluminum into the interstitial spaces between SiC particles, overcoming the material's natural resistance to flow and bond.

The Mechanics of Densification

Forcing Plastic Flow

The primary mechanism for densification is the induction of plastic flow within the aluminum matrix.

When the matrix alloy reaches a solid-liquid or molten state, the furnace applies substantial external pressure (often uniaxial).

This pressure forces the softened aluminum to deform and flow around the rigid SiC particles, filling the microscopic voids that naturally occur between powder particles.

Elimination of Stubborn Porosity

In pressureless sintering, voids often remain because there is no driving force to collapse them.

The vacuum hot press actively compacts the material, mechanically closing these gaps.

This results in a significant increase in material density compared to methods that rely solely on thermal diffusion.

Disrupting Surface Oxides

Aluminum naturally forms a tough oxide film that hinders bonding.

The mechanical shearing forces generated by hot pressing help disrupt and break these oxide layers on the particle surfaces.

This exposure allows for better atomic diffusion and stronger bonding between the aluminum matrix and the SiC reinforcement.

The Role of the Vacuum Environment

Prevention of Matrix Oxidation

Aluminum is highly reactive and oxidizes rapidly at high temperatures.

The vacuum environment (often around $10^{-5}$ mbar) creates an oxygen-free zone during the heating phase.

This prevents the formation of new oxide layers that would otherwise degrade the thermal and mechanical properties of the composite.

Effective Degassing

Raw powders often contain adsorbed gases or volatiles that release during heating.

The vacuum effectively evacuates these gases from the interstitial spaces between the powder particles.

By removing these volatiles before the matrix fully densifies, the process prevents gas pockets from becoming trapped inside the final composite.

Understanding the Trade-offs

Process Constraints

While vacuum hot pressing yields superior density, it is typically a batch process rather than a continuous one.

This limits production speed compared to casting methods, making it more suitable for high-performance components than mass-market commodities.

Complexity of Control

Achieving the ideal density requires precise synchronization of temperature, pressure, and vacuum levels.

If pressure is applied too early (before the matrix softens) or too late, the densification will be incomplete, or the SiC particles may fracture.

Making the Right Choice for Your Project

The decision to use a vacuum hot press furnace depends on the specific performance requirements of your composite material.

- If your primary focus is mechanical strength and reliability: The vacuum hot press is essential to achieve the near-zero porosity and high interfacial bonding required for structural integrity.

- If your primary focus is thermal conductivity: The vacuum environment is critical to prevent oxidation at the interface, ensuring maximum heat transfer efficiency between the matrix and reinforcement.

By leveraging the combination of vacuum purity and mechanical force, you transform a loose mixture of powders into a cohesive, high-performance engineered material.

Summary Table:

| Mechanism | Role in Densification | Impact on Material Quality |

|---|---|---|

| Plastic Flow | Forces molten/softened Al into SiC gaps | Eliminates stubborn microscopic voids |

| Uniaxial Pressure | Mechanically collapses internal pores | Achieves superior material density |

| Vacuum Environment | Degasses volatiles and prevents oxidation | Ensures high interfacial bonding & purity |

| Mechanical Shearing | Disrupts surface oxide layers | Promotes atomic diffusion and strength |

Elevate Your Composite Performance with KINTEK

Precision is the difference between a loose mixture and a high-performance material. Backed by expert R&D and manufacturing, KINTEK offers high-vacuum Hot Press systems, Muffle, Tube, Rotary, and CVD furnaces—all fully customizable to your specific SiC/Al composite requirements. Our technology ensures near-zero porosity and superior thermal conductivity for your most demanding lab and production needs.

Ready to optimize your densification process? Contact KINTEK today to discuss your custom solution.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why is a Vacuum Hot Press (VHP) furnace more suitable for preparing ODS alloys? Superior Uniformity & Density

- What is the maximum working temperature of a vacuum hot press furnace? Achieve Precise High-Temp Processing

- How to maintain a vacuum machine? Ensure long-term reliability and peak performance

- Why are pressure and temperature control crucial for Cu-CNT composites? Eliminate Delamination in Vacuum Hot Pressing

- How is Vacuum Hot Press equipment utilized in the aerospace industry? Essential for High-Performance Component Manufacturing

- How does the pressure control function in a vacuum hot pressing sintering furnace influence ceramic tool materials?

- What are the benefits of a heat press machine? Achieve Professional, Durable Results

- What role does Hexagonal Boron Nitride (h-BN) coating play in SPS molds? Protect Your Tooling and Purity