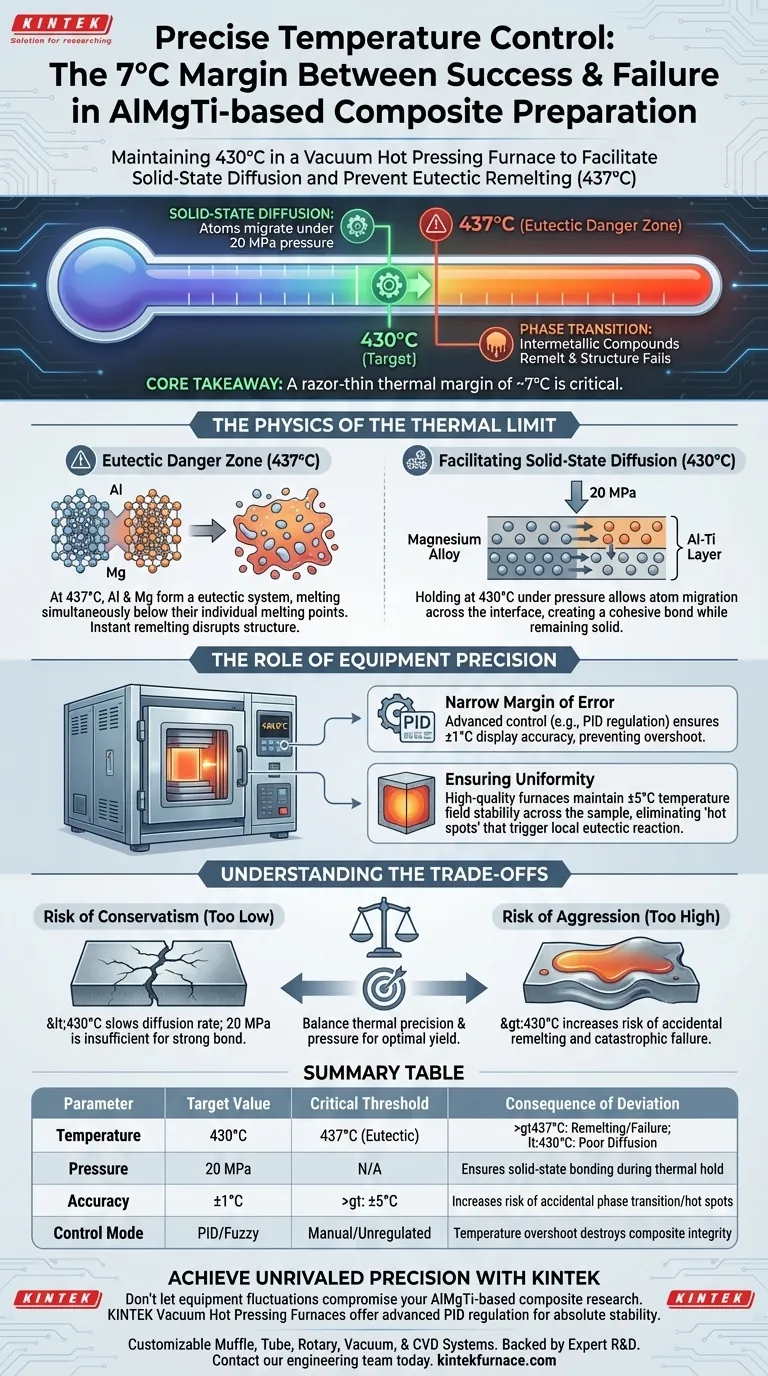

Precise temperature control is the only barrier between successful bonding and structural failure. In the preparation of AlMgTi-based composites, the temperature must be strictly maintained at 430°C to facilitate solid-state diffusion. This specific target is critical because it sits just below the eutectic temperature of aluminum and magnesium (437°C); exceeding this limit by even a few degrees causes the intermetallic compounds to remelt, effectively destroying the composite's integrity.

Core Takeaway The success of this process relies on a razor-thin thermal margin of approximately 7°C. You must maintain enough heat to activate diffusion bonding at 430°C, but absolute precision is required to avoid crossing the 437°C threshold where the material transitions from solid to liquid phase.

The Physics of the Thermal Limit

The Eutectic Danger Zone

The fundamental constraint in this process is the eutectic temperature of the aluminum and magnesium components.

At exactly 437°C, these two metals form a eutectic system, meaning they will melt simultaneously at a temperature lower than the melting point of either individual metal.

Preventing Phase Transition

If the furnace temperature exceeds this 437°C limit, the generated intermetallic compounds will instantly remelt.

This phase change from solid to liquid disrupts the material structure. It undoes the bonding process and creates inconsistencies within the composite layers.

Facilitating Solid-State Diffusion

The goal is to achieve a solid-state diffusion bond, not a liquid fusion.

By holding the temperature at 430°C, you provide just enough thermal energy for atoms to migrate across the interface between the magnesium alloy and the Al-Ti layer. This must occur while the material remains solid, assisted by a high external pressure of 20 MPa.

The Role of Equipment Precision

Narrowing the Margin of Error

Because the operational target (430°C) is dangerously close to the failure point (437°C), standard heating elements are insufficient.

A vacuum hot pressing furnace is required because it utilizes advanced control systems, such as PID regulation and fuzzy control. These technologies ensure the temperature display accuracy remains within ±1°C.

Ensuring Uniformity

In addition to accuracy at a single point, the temperature field stability across the entire sample is vital.

High-quality furnaces maintain stability within ±5°C. This ensures that "hot spots" do not develop on the sample, which could locally trigger the eutectic reaction even if the main sensor reads 430°C.

Understanding the Trade-offs

The Risk of Conservatism

It might seem logical to lower the temperature well below 430°C to stay safe, but this creates a new problem.

If the temperature is too low, the diffusion rate of the atoms slows down significantly. Without sufficient thermal energy, the 20 MPa of pressure will not be enough to create a strong, cohesive bond between the layers.

The Risk of Aggression

Conversely, pushing the temperature closer to the 437°C limit to speed up diffusion is a gamble with material integrity.

Given that even advanced furnaces have slight fluctuations, aiming too high increases the statistical probability of accidental remelting. You are trading process speed for a high risk of catastrophic part failure.

Making the Right Choice for Your Goal

To maximize the yield of your AlMgTi-based composite, you must balance thermal precision with pressure application.

- If your primary focus is Structural Integrity: Calibrate your PID controller to ensure zero overshoot above 430°C, prioritizing the solid-state nature of the bond over speed.

- If your primary focus is Bonding Quality: Ensure the 20 MPa pressure is applied consistently throughout the 430°C hold time to maximize diffusion without relying on higher temperatures.

- If your primary focus is Process Repeatability: Utilize a furnace with multi-zone control to maintain a uniform thermal field, eliminating local hot spots that could trigger the eutectic reaction.

Success in this stage is defined by your ability to hover right at the edge of the phase change without ever crossing it.

Summary Table:

| Parameter | Target Value | Critical Threshold | Consequence of Deviation |

|---|---|---|---|

| Temperature | 430°C | 437°C (Eutectic) | >437°C: Remelting/Structural Failure; <430°C: Poor Diffusion |

| Pressure | 20 MPa | N/A | Ensures solid-state bonding during thermal hold |

| Accuracy | ±1°C | > ±5°C | Increases risk of accidental phase transition/hot spots |

| Control Mode | PID/Fuzzy | Manual/Unregulated | Temperature overshoot destroys composite integrity |

Achieve Unrivaled Precision in Your Composite Research

Success in AlMgTi-based composite preparation depends on a razor-thin 7°C margin. Don't let equipment fluctuations compromise your structural integrity. KINTEK provides industry-leading Vacuum Hot Pressing Furnaces engineered with advanced PID regulation to maintain the absolute stability your materials demand.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable for your unique lab requirements. Ensure your bonding process is repeatable and fail-safe with our high-temp solutions.

Ready to elevate your material performance? Contact our engineering team today to find the perfect furnace for your application.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What functions do graphite molds serve in the vacuum hot pressing of copper-carbon nanotube composites?

- What are the core functions of graphite molds in the hot press sintering process of Nb-22.5Cr-5Si alloys? Find Out Now

- What are the advantages of ceramic/metal composites produced using a vacuum press? Achieve Superior Strength and Durability

- What are the common applications of hot press furnaces? Unlock High-Density Material Solutions

- Why is Vacuum Hot Press equipment considered a cornerstone of modern manufacturing? Unlock Superior Material Density and Purity

- What are the advantages of using a vacuum hot press? Achieve Superior Material Quality and Precision

- What is a vacuum press used for? Achieve Flawless Bonding and Material Transformation

- How does the programmable pressure function of a vacuum hot press furnace influence the quality of IZO targets?