At its core, hot pressing is the manufacturing method of choice for creating advanced ceramic components where failure is not an option. Its applications range from silicon nitride cutting tools and boron carbide armor to specialized electronic materials like PLZT. The process is used to forge ceramics with near-perfect density, granting them exceptional strength, hardness, and unique functional properties that are unattainable through conventional methods.

Hot pressing is not for common ceramics. It is a specialized, high-cost process reserved for applications where maximum density, superior mechanical strength, and exceptional wear resistance are the absolute primary requirements.

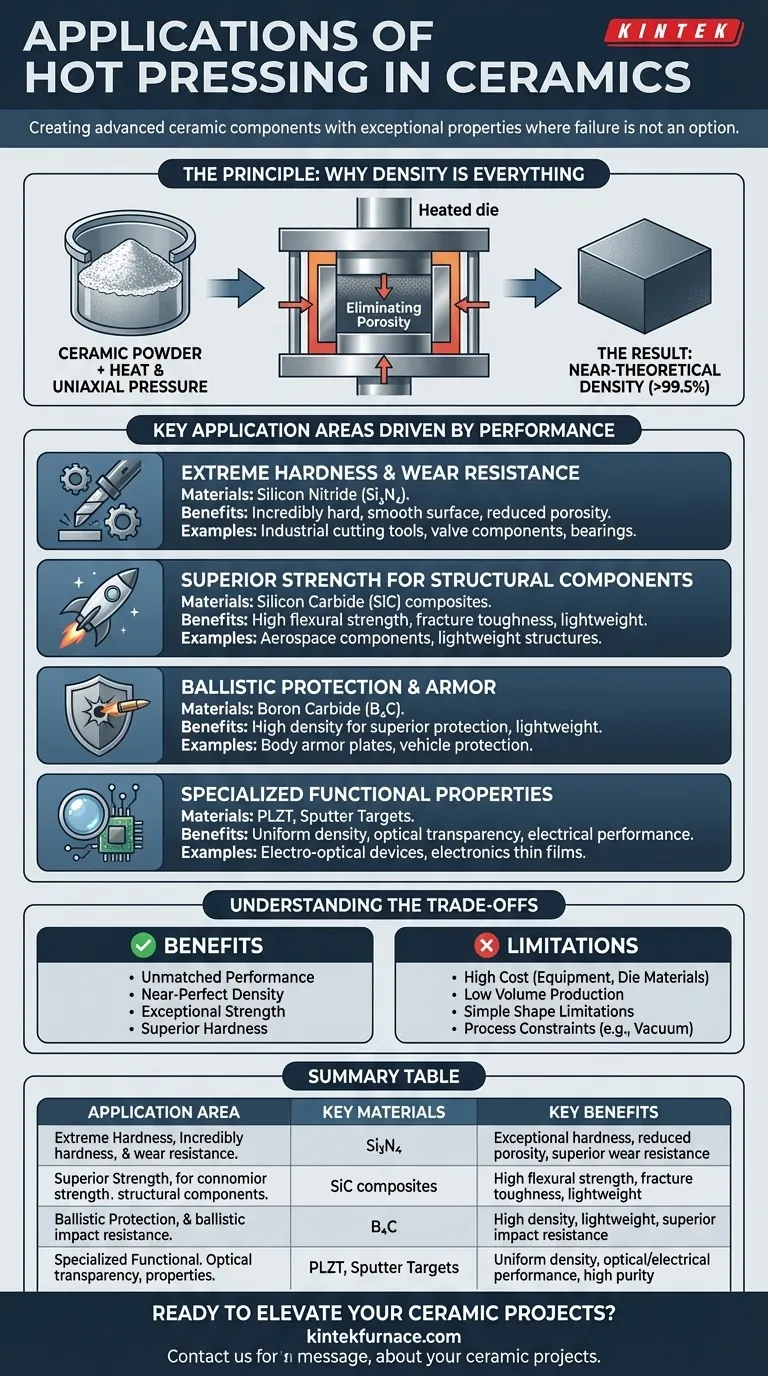

The Principle: Why Density is Everything

Hot pressing is a powder metallurgy process that combines high temperature and uniaxial pressure simultaneously. This combination is the key to its unique capabilities.

Eliminating Porosity

In conventional sintering, ceramic powders are heated until their particles fuse together, but this often leaves behind small voids or pores. These pores are microscopic stress concentrators, acting as the primary failure points in a ceramic part.

Hot pressing directly counteracts this. The applied heat softens the ceramic particles, while the immense pressure forces them into a tightly packed arrangement, effectively squeezing out the voids.

The Result: Near-Theoretical Density

This process results in a final product that is exceptionally dense—often greater than 99.5% of the material's theoretical maximum density. This near-perfect microstructure is the foundation for the material's enhanced performance.

Key Application Areas Driven by Performance

The decision to use hot pressing is always driven by the need for a specific, high-level performance characteristic that less advanced processes cannot deliver.

Extreme Hardness and Wear Resistance

By eliminating porosity, hot pressing creates an incredibly hard and smooth surface. This is critical for components subjected to intense friction and abrasion.

Examples include silicon nitride (Si₃N₄) and mixed ceramics for industrial cutting tools, heavy-duty valve components, and high-performance bearings.

Superior Strength for Structural Components

Dense, pore-free ceramics have dramatically higher flexural strength and fracture toughness. This allows them to be used in demanding structural and load-bearing roles.

This is essential in aerospace, where hot-pressed ceramic matrix composites (CMCs), like silicon carbide (SiC) whisker-reinforced alumina, are used for lightweight, high-strength components that can withstand extreme temperatures.

Ballistic Protection and Armor

For armor applications, a material must be extremely hard to shatter an incoming projectile and lightweight enough to be practical.

Hot-pressed boron carbide (B₄C) is a premier material for body armor plates and vehicle protection. The process achieves the high density needed to provide a superior level of protection for its weight.

Specialized Functional Properties

For certain "functional" ceramics, performance depends on a perfectly uniform and dense internal structure to control the flow of light or electricity.

Hot-pressed PLZT (lead-lanthanum-zirconate-titanate) is used to create transparent ceramics for electro-optical devices. Similarly, high-purity sputter targets, used in the electronics industry to deposit thin films, are hot-pressed to ensure uniform density and composition.

Understanding the Trade-offs

Hot pressing provides unmatched performance, but this comes with significant practical and economic limitations that are critical to understand.

High Cost and Low Volume

The equipment—high-temperature presses and specialized die materials like graphite—is expensive to purchase and operate. The process is also slower than conventional sintering, making it unsuitable for high-volume, low-cost production.

Shape Complexity Limitations

Because the pressure is applied along a single axis (uniaxial), hot pressing is best suited for producing simple shapes like discs, plates, and cylinders. Manufacturing complex, three-dimensional parts is extremely difficult and often impossible.

Material and Process Constraints

The ceramic powder cannot react with the die material at high temperatures. This limits the choice of die and the maximum processing temperature. Furthermore, many materials require processing in a vacuum or a controlled atmosphere to prevent oxidation, adding further complexity and cost.

When to Specify Hot Pressing

Choosing the right manufacturing process requires balancing performance needs against economic and design realities.

- If your primary focus is mechanical failure prevention: Specify hot pressing for components that demand the absolute highest strength, hardness, and wear resistance, such as cutting tools, armor, or critical-wear parts.

- If your primary focus is specialized material properties: Use hot pressing for functional materials like transparent ceramics or high-purity sputter targets where full density is essential for optical, thermal, or electrical performance.

- If your primary focus is cost-efficiency for a standard application: Explore conventional sintering or other methods first. Only turn to hot pressing if the performance requirements absolutely cannot be met otherwise.

By understanding its principles and limitations, you can strategically leverage hot pressing to engineer ceramic components that achieve unparalleled levels of performance.

Summary Table:

| Application Area | Key Materials | Key Benefits |

|---|---|---|

| Extreme Hardness & Wear Resistance | Silicon Nitride (Si₃N₄) | Exceptional hardness, reduced porosity, superior wear resistance |

| Superior Strength for Structural Components | Silicon Carbide (SiC) composites | High flexural strength, fracture toughness, lightweight |

| Ballistic Protection & Armor | Boron Carbide (B₄C) | High density, lightweight, superior impact resistance |

| Specialized Functional Properties | PLZT, Sputter Targets | Uniform density, optical/electrical performance, high purity |

Ready to elevate your ceramic projects with high-performance solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're developing cutting tools, armor, or specialized electronic materials, we can help you achieve unparalleled density and strength. Contact us today to discuss how our expertise can drive your innovations forward!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%