The core role of a Vacuum Hot Pressing (VHP) furnace in preparing Zinc Sulfide (ZnS) ceramics is to drive rapid densification while strictly controlling the material's purity. By simultaneously applying uniaxial mechanical pressure (typically 15–20 MPa) and high temperatures (960°C–1040°C) within a vacuum, the furnace forces ceramic particles to rearrange and bond. This process eliminates the micro-pores and oxidation that otherwise destroy infrared transparency.

The VHP Advantage: VHP does not rely on heat alone to sinter materials; it uses mechanical force to achieve near-theoretical density at lower temperatures. This unique combination suppresses excessive grain growth and eliminates light-scattering defects, producing a ceramic that is both optically clear and mechanically superior to many alternatives.

The Mechanics of Densification

Pressure-Assisted Sintering

The defining feature of a VHP furnace is the application of significant mechanical pressure, often around 15 to 20 MPa. Unlike pressureless sintering, which relies solely on thermal energy to fuse particles, VHP physically forces ZnS nanopowders together.

Plastic Flow and Rearrangement

This mechanical force promotes the plastic flow of the material and the physical rearrangement of particles. By mechanically closing the gaps between particles, the system achieves high density without requiring the extreme temperatures that might degrade the material.

Preventing Grain Growth

Because the applied pressure facilitates densification at lower thermal thresholds (e.g., around 1020°C), the process suppresses excessive grain growth. Maintaining a fine, uniform grain structure is critical for the mechanical integrity of the final ceramic.

Achieving High Infrared Transmittance

The Vacuum Environment

A high vacuum (approximately $10^{-3}$ Torr) is non-negotiable for optical-grade ZnS. This environment actively extracts residual volatile impurities and adsorbed gases trapped within the powder interstices.

Eliminating Light Scattering

The primary enemy of infrared transmission is porosity. Even microscopic air pockets scatter light, reducing transparency. The combination of vacuum extraction and mechanical compression effectively squeezes out these micro-pores, ensuring the light path is unobstructed.

Oxidation Prevention

Zinc Sulfide is susceptible to oxidation and decomposition at high sintering temperatures. The vacuum environment shields the material from oxygen, preserving the chemical purity required for optimal optical performance.

Comparing VHP to Alternatives

Enhanced Mechanical Properties

VHP-processed ZnS ceramics often exhibit superior mechanical properties compared to those produced by Chemical Vapor Deposition (CVD). Specifically, VHP can yield significantly higher hardness (e.g., 321 kgf/mm²), making it the preferred method for infrared windows that must withstand harsh physical environments.

Cost and Efficiency

The VHP process is generally simpler and faster than CVD. It offers a shorter production cycle and lower operational costs while still delivering high-quality, near-net-shape components.

Understanding the Trade-offs

Geometric Constraints

While VHP is excellent for plates, discs, and simple shapes, it has limitations regarding geometry. The uniaxial pressure is applied via rams, making it difficult to produce complex, non-symmetrical 3D shapes without extensive post-processing.

Throughput Limitations

VHP is typically a batch process. While faster than CVD for individual cycles, the physical constraints of the die and the press size limit the volume of parts that can be produced simultaneously compared to continuous sintering methods.

Making the Right Choice for Your Goal

When evaluating VHP for your Zinc Sulfide project, consider your specific performance metrics:

- If your primary focus is Optical Clarity: Prioritize the vacuum quality to ensure total removal of micro-pores, as this is the deciding factor in minimizing light scattering.

- If your primary focus is Durability: Leverage the VHP process to maximize hardness, which offers better erosion resistance than standard CVD materials.

- If your primary focus is Cost Efficiency: Utilize VHP for its shorter cycle times and lower equipment costs relative to vapor deposition techniques.

Ultimately, the VHP furnace bridges the gap between raw powder and high-performance optics by replacing thermal intensity with mechanical precision, delivering a denser, harder, and clearer final product.

Summary Table:

| Feature | VHP Furnace Benefit for ZnS | Impact on Performance |

|---|---|---|

| Pressure (15-20 MPa) | Forces plastic flow & particle rearrangement | Achieves near-theoretical density |

| High Vacuum ($10^{-3}$ Torr) | Removes volatile impurities & trapped gases | Eliminates light scattering & oxidation |

| Thermal Control | Sintering at lower thresholds (960-1040°C) | Suppresses grain growth for high hardness |

| Mechanical Force | Direct uniaxial compression | Superior hardness compared to CVD methods |

Elevate Your Infrared Optics with KINTEK Precision

Don't let micro-pores and oxidation compromise your optical performance. KINTEK’s advanced Vacuum Hot Pressing (VHP) systems are engineered to deliver the mechanical precision and vacuum integrity required for superior ZnS ceramic production.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your laboratory's unique high-temperature needs. Whether you are optimizing for optical clarity, material hardness, or cost-efficient batch production, our experts are ready to help you design the perfect thermal solution.

Contact KINTEK Today for a Customized Quote

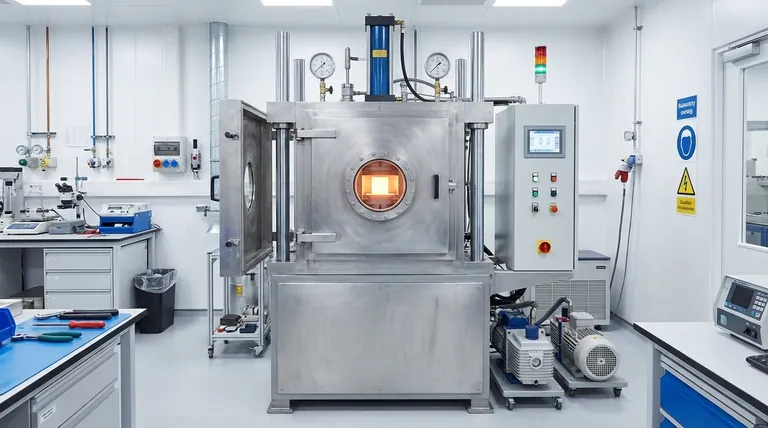

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What role do high-power heating plates play in vacuum contact drying furnaces? Unlock Rapid Thermal Diffusion

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?