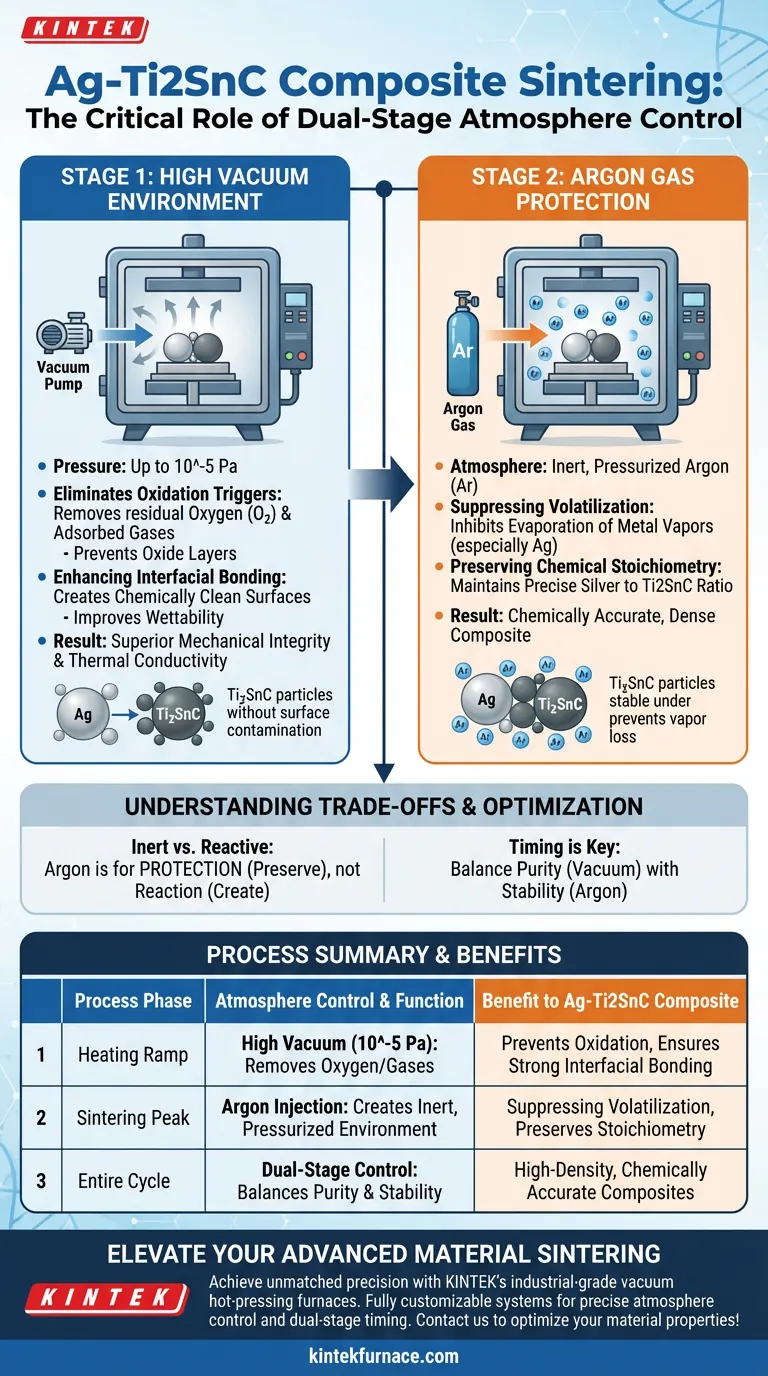

The dual-stage control of atmosphere within an industrial-grade vacuum hot-pressing furnace is the deciding factor in the quality of Silver-Titanium Silicon Carbide (Ag-Ti2SnC) composites.

The process relies on a high vacuum (up to 10^-5 Pa) to strip away residual oxygen, preventing the oxidation of the silver matrix and Ti2SnC particles. This is immediately followed by the injection of argon gas, which creates an inert pressurized environment to stop metal vapors from evaporating, ensuring the final chemical composition remains true to the design.

By effectively removing contaminants via vacuum and stabilizing the material with argon, the furnace prevents both the formation of brittle oxides and the loss of volatile metallic elements, ensuring a dense, chemically accurate composite.

The Role of the Vacuum Environment

Eliminating Oxidation Triggers

The primary function of the vacuum system is to lower pressure to extreme levels, often reaching 10^-5 Pa. At this threshold, residual oxygen is effectively evacuated from the chamber.

This is critical because both the silver (Ag) matrix and the Ti2SnC reinforcement particles are susceptible to early oxidation during the heating phase. Removing oxygen prevents the formation of oxide layers on the particle surfaces.

Enhancing Interfacial Bonding

When the powder surfaces are stripped of adsorbed gases and potential oxides, they are chemically "clean." This purification improves the wettability of the Ti2SnC particles by the silver matrix.

Clean surfaces allow for direct contact between the matrix and the reinforcement. This results in superior interfacial bonding strength, which is fundamental to the mechanical integrity and thermal conductivity of the final composite.

The Role of Argon Gas Protection

Suppressing Volatilization

While a vacuum is excellent for cleaning, maintaining a high vacuum at peak sintering temperatures can cause certain metals to vaporize. To counter this, argon gas is injected into the chamber after the initial vacuum stage.

This creates an inert, pressurized atmosphere. The pressure exerted by the argon inhibits the volatilization of metal vapors, which is a common risk when processing silver-based composites at high heat.

Preserving Chemical Stoichiometry

The precise ratio of silver to Ti2SnC is what dictates the material's properties. If the metal matrix were allowed to evaporate, the material would drift from its intended design proportions.

Argon protection ensures that the chemical composition of the sintered body matches the original powder mixture. This stability guarantees that the final physical properties—such as conductivity and hardness—align with the engineering specifications.

Understanding the Trade-offs

Inert vs. Reactive Atmospheres

It is important to distinguish between protection and reaction. The argon atmosphere described here is inert—its sole purpose is to preserve the material state and prevent loss.

This contrasts with sintering processes that use reactive gases (like nitrogen) to intentionally form new reinforcement phases (such as Aluminum Nitride). With Ag-Ti2SnC, the goal is retention of the original chemistry, not the creation of new compounds during sintering.

Complexity of Dual-Stage Processing

Implementing a cycle that requires extreme vacuum (10^-5 Pa) followed by precise gas backfilling adds complexity to the thermal cycle.

If the transition to argon happens too late, volatilization may already have occurred. If it happens too early, residual oxygen may not be fully evacuated, leading to trapped impurities. Precise timing is required to balance purity with stability.

Making the Right Choice for Your Goal

To maximize the performance of your Ag-Ti2SnC composites, you must tailor the furnace parameters to your specific failure modes.

- If your primary focus is mechanical strength: Prioritize the vacuum level (10^-5 Pa) during the heating ramp to ensure zero oxide formation at the particle interfaces.

- If your primary focus is compositional accuracy: Prioritize the timing of the argon injection to ensure the chamber is pressurized before the temperature reaches the vaporization point of silver.

The most successful sintering runs occur when the vacuum cleans the stage, and the argon locks in the chemistry.

Summary Table:

| Process Phase | Atmosphere Control | Primary Function | Benefit to Ag-Ti2SnC Composite |

|---|---|---|---|

| Heating Ramp | High Vacuum (10^-5 Pa) | Removes residual oxygen & adsorbed gases | Prevents oxidation; ensures strong interfacial bonding |

| Sintering Peak | Argon Gas Injection | Creates inert, pressurized environment | Suppresses metal volatilization; preserves stoichiometry |

| Entire Cycle | Dual-Stage Control | Balances purity and stability | Results in high-density, chemically accurate composites |

Elevate Your Advanced Material Sintering

Achieve unmatched precision in your Ag-Ti2SnC and metal-matrix composite production with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized industrial-grade vacuum hot-pressing furnaces.

Our systems provide the precise atmosphere control and dual-stage timing required to prevent oxidation and ensure chemical stoichiometry for your most demanding applications. All systems are fully customizable to meet your unique research or production needs.

Ready to optimize your material properties? Contact our engineering experts today to find the perfect high-temperature solution for your laboratory or facility.

Visual Guide

References

- Xiaochen Huang, Hongyu Chen. Influence of Ti <sub>2</sub> SnC content on arc erosion resistance in Ag–Ti <sub>2</sub> SnC composites. DOI: 10.1515/secm-2022-0244

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- What are the primary advantages of FAST/SPS in Ti-6Al-4V recycling? Transform Efficiency with Solid-State Sintering

- How does a Vacuum Hot-Pressing Furnace facilitate the densification of CaF2? Achieve High Optical Transparency

- What technical advantages does a Spark Plasma Sintering (SPS) system offer for TiB2 ceramics? Unlock Superior Strength

- What is the basic principle of how a vacuum press works? Harness Atmospheric Pressure for Uniform Clamping

- What role does Vacuum Hot Press technology play in the automotive industry? Boost EV Batteries, Safety, and Efficiency

- What role do vacuum presses play in plastic forming and lamination? Essential Guide for Precision Fabrication

- What is the application of hot press furnaces in ceramic processing? Achieve Superior Density and Strength