Spark Plasma Sintering (SPS) fundamentally outperforms traditional hot pressing by utilizing direct pulsed electrical currents to generate heat internally, rather than relying on external heating elements. For TiB2-based ceramics, this technical shift allows for rapid densification that preserves the material's microstructure, resulting in superior mechanical properties that traditional thermal equilibrium methods struggle to achieve.

The Core Insight The defining advantage of SPS is not just speed, but the preservation of microstructure. By combining high-current pulses with synchronized pressure, SPS creates a fully dense TiB2 composite before the grains have time to coarsen, simultaneously maximizing hardness and fracture toughness.

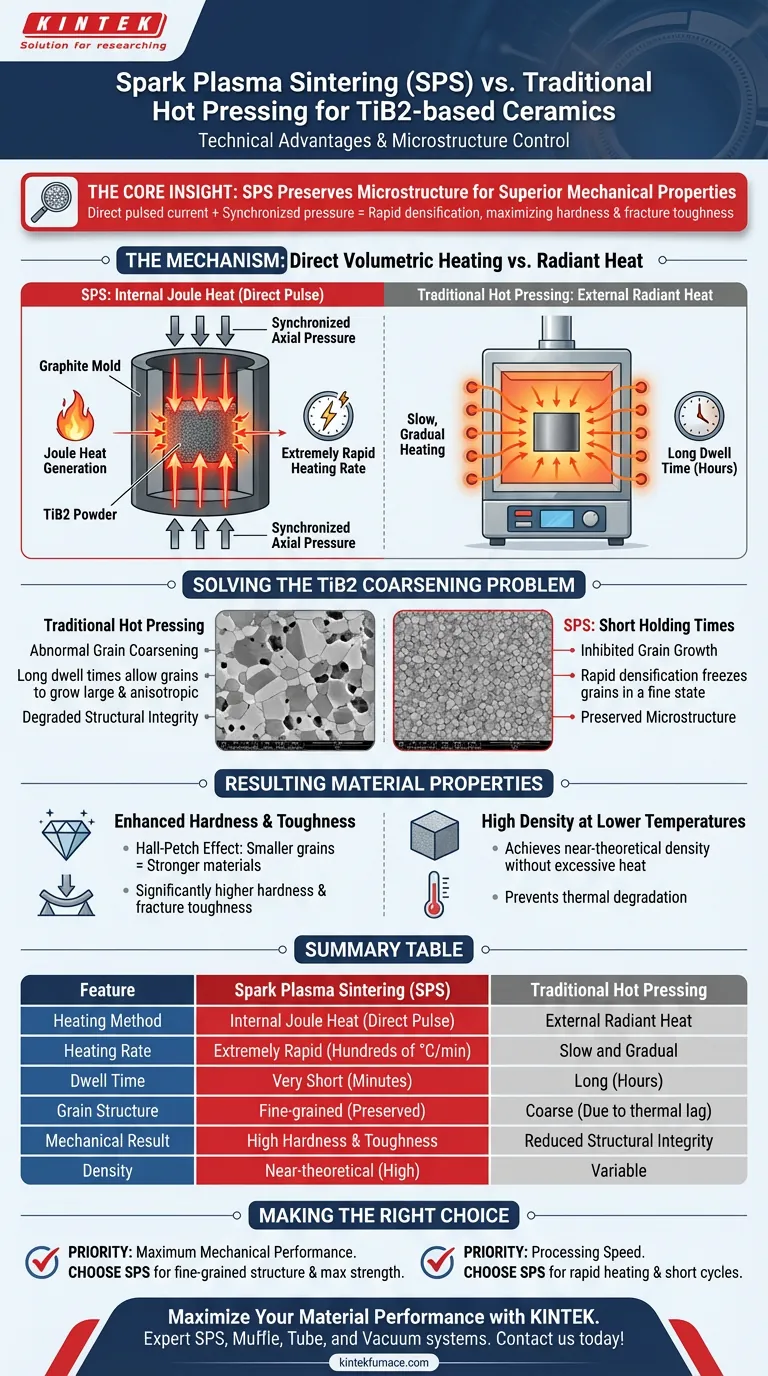

The Mechanism: Direct Volumetric Heating

The primary technical differentiator of an SPS system is how thermal energy is applied to the ceramic powder.

Pulse Current vs. Radiant Heat

Traditional hot pressing relies on radiant heat transfer from external elements, which is a slow process that heats the sample from the outside in. In contrast, SPS generates Joule heat by passing high-current pulses directly through the graphite mold and the sample itself.

Simultaneous Pressurization

While generating this internal heat, the system applies synchronized axial pressure. This combination allows the material to sinter rapidly and uniformly, bypassing the thermal lag inherent in conventional furnaces.

Solving the TiB2 Coarsening Problem

Titanium Diboride (TiB2) ceramics are prone to a specific defect during processing: "abnormal grain coarsening."

Inhibiting Grain Growth

At high temperatures, TiB2 grains naturally tend to grow large and anisotropic (uneven in direction). In traditional hot pressing, the long dwell times required for heat to penetrate the sample give grains ample time to coarsen. This coarsening degrades the material's structural integrity.

The Advantage of Short Holding Times

Because SPS achieves extremely high heating rates, the holding time (dwell time) at high temperatures is significantly reduced. The process completes the densification phase so quickly that the TiB2 grains are effectively "frozen" in a fine state. They simply do not have the time to undergo uncontrolled growth.

Resulting Material Properties

The direct result of inhibiting grain growth is a measurable improvement in the physical performance of the final ceramic.

Enhanced Hardness and Toughness

Mechanical properties in ceramics are often governed by the Hall-Petch relationship: smaller grains typically yield stronger materials. By maintaining a fine-grained microstructure, SPS-produced TiB2 exhibits significantly higher hardness and fracture toughness compared to hot-pressed equivalents.

High Density at Lower Temperatures

SPS allows TiB2 composites to achieve high relative density (near-theoretical density) without requiring the excessive thermal loads often needed in traditional furnaces. This efficiency prevents thermal degradation while ensuring a solid, non-porous end product.

Understanding the Trade-offs

While SPS offers superior material properties for TiB2, it introduces specific operational constraints compared to traditional methods.

The Necessity of Precision

The advantage of SPS relies entirely on the kinetic control of the process. Because heating rates are so rapid (often hundreds of degrees per minute), the window for error is small. Extending the holding time even slightly beyond the optimal point can negate the benefits, allowing the very grain growth the system is designed to prevent.

Conductivity Requirements

The generation of Joule heat requires the current to flow through the mold and/or sample. This creates a dependency on the electrical conductivity of the tooling (typically graphite) and influences how the sample itself is heated, distinct from the purely thermal environment of a hot press.

Making the Right Choice for Your Goal

Deciding between SPS and hot pressing depends on whether your priority is microstructural perfection or conventional processing.

- If your primary focus is Maximum Mechanical Performance: Choose SPS to achieve a fine-grained microstructure that maximizes both hardness and fracture toughness.

- If your primary focus is Processing Speed: Choose SPS to utilize rapid heating rates and short holding times, significantly reducing the overall production cycle.

SPS is the definitive choice when the application demands a TiB2 ceramic that retains fine-grain mechanical strength without sacrificing density.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Traditional Hot Pressing |

|---|---|---|

| Heating Method | Internal Joule Heat (Direct Pulse) | External Radiant Heat |

| Heating Rate | Extremely Rapid (Hundreds of °C/min) | Slow and Gradual |

| Dwell Time | Very Short (Minutes) | Long (Hours) |

| Grain Structure | Fine-grained (Preserved) | Coarse (Due to thermal lag) |

| Mechanical Result | High Hardness & Toughness | Reduced Structural Integrity |

| Density | Near-theoretical (High) | Variable |

Maximize Your Material Performance with KINTEK

Don't let grain coarsening compromise your ceramic research. Backed by expert R&D and manufacturing, KINTEK offers cutting-edge SPS, Muffle, Tube, and Vacuum systems designed to give you precise kinetic control over your sintering process. Whether you need a standard setup or a customizable solution for unique TiB2-based composites, our lab high-temp furnaces deliver the uniform heating and rapid densification your project demands.

Ready to achieve superior material properties? Contact our experts today to find the perfect sintering solution for your lab!

Visual Guide

References

- Sha Zhang, Shuge Tian. Spectral characterization of the impact of modifiers and different prepare temperatures on snow lotus medicinal residue-biochar and dissolved organic matter. DOI: 10.1038/s41598-024-57553-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the basic principle of how a vacuum press works? Harness Atmospheric Pressure for Uniform Clamping

- Why is a vacuum environment important in hot pressing? Essential for Purity and High-Density Materials

- What is the purpose of in-situ reaction/hot pressing for (Ti0.95Nb0.05)3SiC2 targets? Achieve High Density Coatings

- What are the core advantages of high-vacuum hot press sintering for Al2O3/TiC ceramics? Achieve Near-Theoretical Density

- How does the high vacuum environment provided by a vacuum hot press furnace influence the properties of Cu/rGO composites? Achieve Superior Composite Performance

- What are some specific applications of vacuum hot press furnaces? Unlock Advanced Material Fabrication

- How does hot pressing improve mechanical properties of materials? Achieve Superior Strength and Durability

- Why is precise temperature control critical in AlMgTi composite preparation? Mastering the 437°C Eutectic Barrier