In the context of preparing high-performance stainless steel, pressure parameters in a laboratory vacuum hot press act as a critical mechanical force that drives densification independent of temperature. By applying continuous uniaxial pressure, you force powder particles to undergo plastic deformation and creep, effectively filling interstitial voids and achieving high density without the excessive heat that degrades material properties.

Core Takeaway Pressure serves as a kinetic substitute for thermal energy. By mechanically forcing particles together, you can achieve full densification at lower temperatures or shorter timeframes; this preserves fine grain structures and results in stainless steel with superior hardness and mechanical strength.

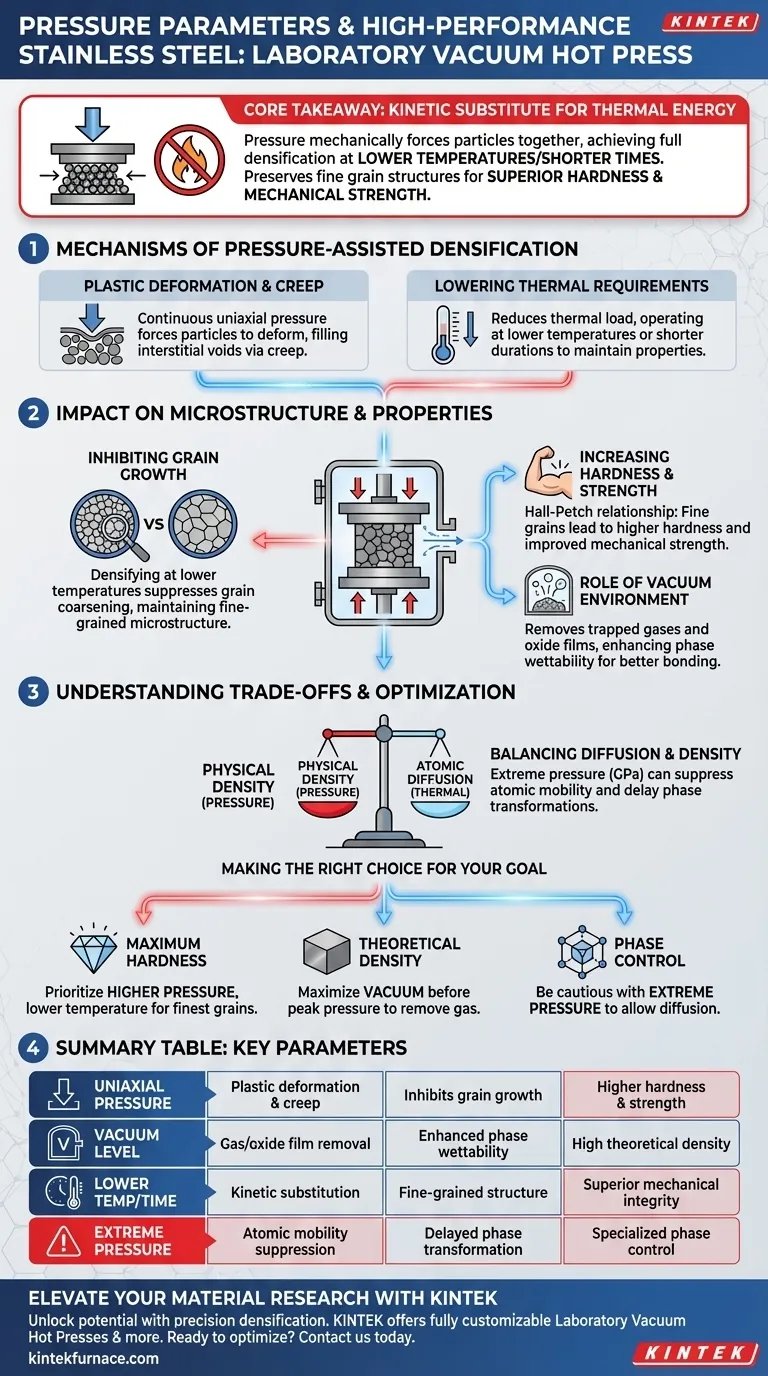

The Mechanisms of Pressure-Assisted Densification

Plastic Deformation and Creep

The primary function of pressure is to overcome the physical resistance of the material particles. Continuous uniaxial pressure forces particles to deform plastically, physically squeezing them into the gaps (interstitial voids) between them.

This mechanism relies on creep, where material moves slowly under mechanical stress. This effectively eliminates porosity that thermal sintering alone might leave behind.

Lowering Thermal Requirements

Because pressure actively closes pores, the process requires less thermal energy to achieve densification.

This allows you to operate at lower temperatures or for shorter durations than conventional sintering would require. This reduction in thermal load is the key to maintaining high-performance characteristics.

Impact on Microstructure and Properties

Inhibiting Grain Growth

The most significant advantage of using pressure to lower processing temperatures is the suppression of grain growth.

High temperatures typically cause grains to coarsen, which softens the metal. By densifying at lower temperatures, you maintain a fine-grained microstructure.

Increasing Hardness and Strength

The direct correlation between grain size and strength (Hall-Petch relationship) means that the pressure-assisted preservation of fine grains leads to measurable performance gains.

The resulting stainless steel exhibits higher hardness and improved mechanical strength compared to samples processed via pressureless sintering.

The Role of the Vacuum Environment

While pressure drives physical densification, the vacuum environment plays a distinct, supporting role.

Vacuum facilitates the escape of trapped gases and removes oxide films before the liquid phase appears. This enhances the wettability of the phases, ensuring that when pressure is applied, the material bonds rather than just compressing trapped gas pockets.

Understanding the Trade-offs

Suppression of Atomic Mobility

It is critical to note that extremely high pressure (specifically at the GPa level) can inhibit atomic diffusion.

While pressure forces contact, it can simultaneously suppress atomic mobility, delaying the transformation from amorphous to crystalline phases.

Balancing Diffusion and Density

If your goal is specific phase transformation, high pressure might delay the process, requiring you to adjust thermal parameters accordingly.

You must balance the pressure needed for physical density with the thermal energy required to allow necessary atomic diffusion for bonding and phase stability.

Making the Right Choice for Your Goal

To optimize your laboratory vacuum hot press parameters, align your settings with your specific material objectives:

- If your primary focus is Maximum Hardness: Prioritize higher pressure to minimize the processing temperature, thereby preserving the finest possible grain structure.

- If your primary focus is Theoretical Density: Ensure the vacuum level is maximized to remove gas prior to applying peak pressure, preventing trapped pores that pressure alone cannot close.

- If your primary focus is Phase Control: Be cautious with extreme pressures (GPa level), as this may suppress the diffusion necessary for certain crystalline formations.

Success depends on using pressure not just to squeeze the material, but to reduce the thermal budget required for densification.

Summary Table:

| Parameter | Primary Mechanism | Impact on Microstructure | Resulting Property |

|---|---|---|---|

| Uniaxial Pressure | Plastic deformation & creep | Inhibits grain growth | Higher hardness & strength |

| Vacuum Level | Gas/oxide film removal | Enhanced phase wettability | High theoretical density |

| Lower Temp/Time | Kinetic substitution | Fine-grained structure | Superior mechanical integrity |

| Extreme Pressure | Atomic mobility suppression | Delayed phase transformation | Specialized phase control |

Elevate Your Material Research with KINTEK

Unlock the full potential of your high-performance alloys by mastering precision densification. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, including advanced Laboratory Vacuum Hot Presses.

Our systems are fully customizable to meet your unique research needs, providing the precise control over pressure and thermal parameters required for superior grain preservation and material strength.

Ready to optimize your lab's efficiency? Contact us today to consult with our experts and find the perfect high-temperature solution for your target applications.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- How should heating elements and pressurization methods be selected for vacuum hot press furnaces? Optimize for Temperature and Density

- What are the advantages of using hot pressing in manufacturing? Achieve Superior Quality and Precision

- What are the advantages of SPS over hot pressing for high-entropy alloys? Achieve Superior Density and Microstructure

- What is the function of a Hot Press Sintering (HPS) furnace? Mastering High-Density Ceramics for PCFC

- How do you maintain a heat press machine? A Proactive Guide to Consistent Prints & Longevity

- How does vacuum hot pressing improve material properties? Achieve Denser, Stronger Materials with Precision

- What is the necessity of maintaining a high vacuum environment during AZ31 sintering? Prevent Oxidation and Porosity

- How does the heating mechanism of Spark Plasma Sintering (SPS) function? Enhance TiC/SiC Composite Fabrication