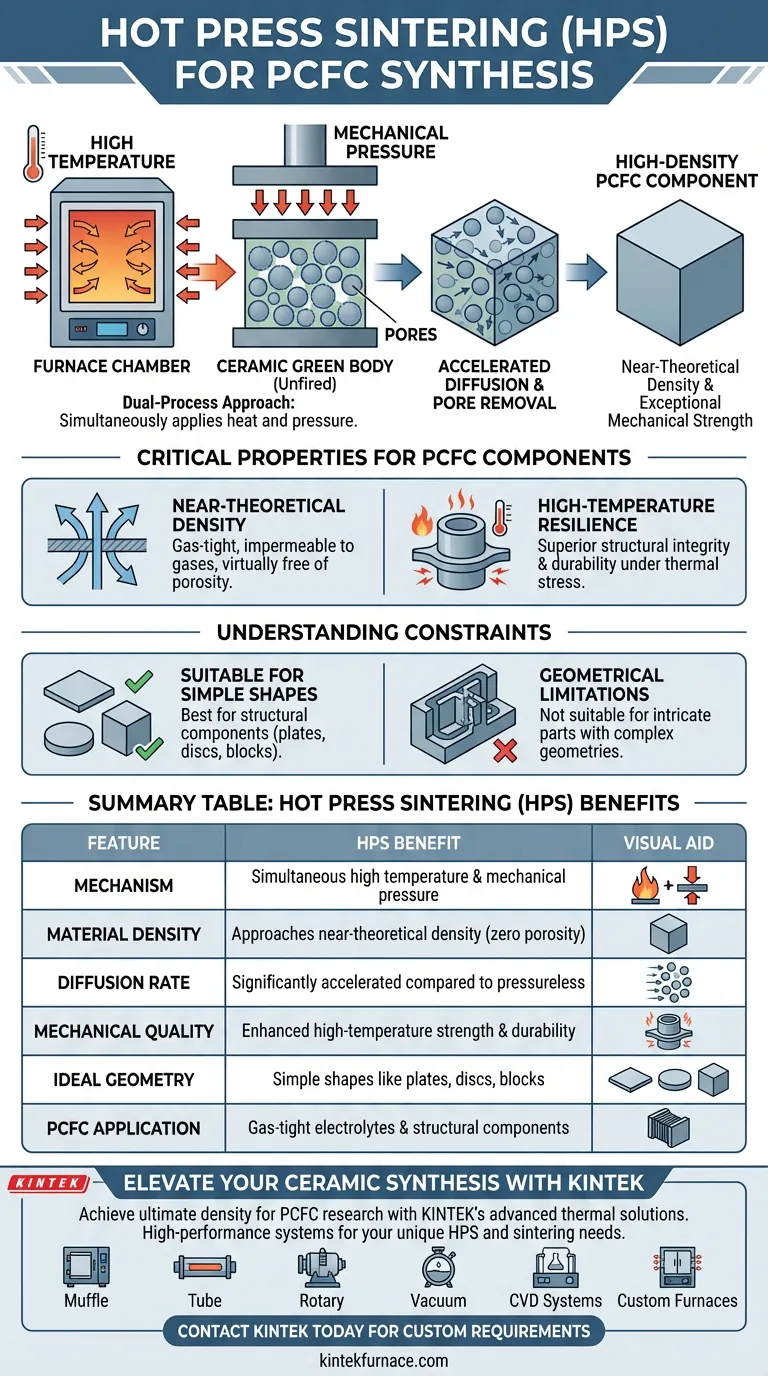

A Hot Press Sintering (HPS) furnace functions by applying mechanical pressure to a ceramic green body while simultaneously subjecting it to high temperatures. This dual-process approach accelerates the removal of internal pores and enhances atomic diffusion, enabling the synthesis of Protonic Ceramic Fuel Cell (PCFC) components that possess near-theoretical density and exceptional mechanical strength.

By combining thermal energy with physical force, HPS overcomes the limitations of standard pressureless sintering. It is uniquely capable of producing the highly dense, structurally robust ceramics required for the rigorous operating conditions of fuel cells.

How HPS Achieves Superior Density

Simultaneous Pressure and Heating

Unlike conventional sintering, which relies primarily on temperature to densify a material, HPS introduces mechanical pressure during the heating phase.

This external force acts directly on the microstructure of the ceramic "green body" (the unfired material).

Accelerating Diffusion

The combination of heat and pressure significantly accelerates the diffusion process within the ceramic material.

This rapid diffusion forces particles together more effectively, expediting the elimination of internal voids and pores that typically remain during standard sintering.

Critical Properties for PCFC Components

Approaching Theoretical Density

For a PCFC to function efficiently, the electrolyte and structural components must be gas-tight to prevent fuel leakage.

HPS allows samples to approach their theoretical density, resulting in a material that is virtually free of porosity and impermeable to gases.

High-Temperature Resilience

PCFCs operate at elevated temperatures, requiring materials that maintain structural integrity under thermal stress.

Components synthesized via HPS exhibit superior high-temperature mechanical properties, ensuring they remain stable and durable during long-term cell operation.

Understanding the Constraints

Geometrical Limitations

While HPS produces superior material properties, the application of mechanical pressure generally restricts the geometry of the final product.

The process is most suitable for components with simple shapes, such as flat plates, discs, or blocks.

Suitability for Structural Parts

Because of these geometric constraints, HPS is best utilized for structural components rather than intricate parts with complex internal channels.

It is the ideal method when the material's internal integrity is more critical than its geometric complexity.

Making the Right Choice for Your Project

While HPS offers unmatched density, it is specific to certain component types. Use the following guide to determine its fit for your PCFC fabrication:

- If your primary focus is gas-tightness and density: HPS is the optimal choice, as it eliminates internal pores more effectively than any pressureless method.

- If your primary focus is mechanical strength: HPS yields components with superior high-temperature properties essential for structural durability.

- If your primary focus is complex geometry: HPS may not be suitable due to its limitation to simple, flat, or block-like shapes.

Ultimately, HPS is the definitive synthesis tool when material performance and density are non-negotiable requirements for your ceramic application.

Summary Table:

| Feature | Hot Press Sintering (HPS) Benefit |

|---|---|

| Mechanism | Simultaneous high temperature and mechanical pressure |

| Material Density | Approaches near-theoretical density (zero porosity) |

| Diffusion Rate | Significantly accelerated compared to pressureless methods |

| Mechanical Quality | Enhanced high-temperature strength and durability |

| Ideal Geometry | Simple shapes like plates, discs, and blocks |

| PCFC Application | Gas-tight electrolytes and structural components |

Elevate Your Ceramic Synthesis with KINTEK

Achieve the ultimate material density for your Protonic Ceramic Fuel Cell research with KINTEK’s advanced thermal solutions. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, including customizable high-temperature furnaces tailored to your unique HPS and sintering needs. Whether you require superior gas-tightness or high-temperature mechanical resilience, our technical experts are ready to provide the precision equipment your lab deserves.

Ready to optimize your high-density ceramic production? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Mengyang Yu, Shenglong Mu. Recent Novel Fabrication Techniques for Proton-Conducting Solid Oxide Fuel Cells. DOI: 10.3390/cryst14030225

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does the pressure-assisted mechanism in a Vacuum Hot Press Furnace improve YAG ceramics? Unlock Optical Clarity

- How does the application of mechanical pressure contribute to the vacuum hot pressing formation of TiAl/Ti6Al4V? Expert Analysis

- What functions does a graphite mold serve during ZnS vacuum hot pressing? Optimize Density and Optical Purity

- What types of heating elements are used in vacuum hot press furnaces? Optimize for High-Temp Performance

- How does activated sintering work for ceramic materials? Lower Temperatures, Faster Densification

- What is the role of the vacuum environment in SiC/ZTA sintering? Enhance Densification & Material Purity

- What are the unique advantages of Spark Plasma Sintering (SPS)? Unlock Ultrafine Carbide Strength

- What is the purpose of vacuum hot pressing? Achieve Superior Material Density and Purity