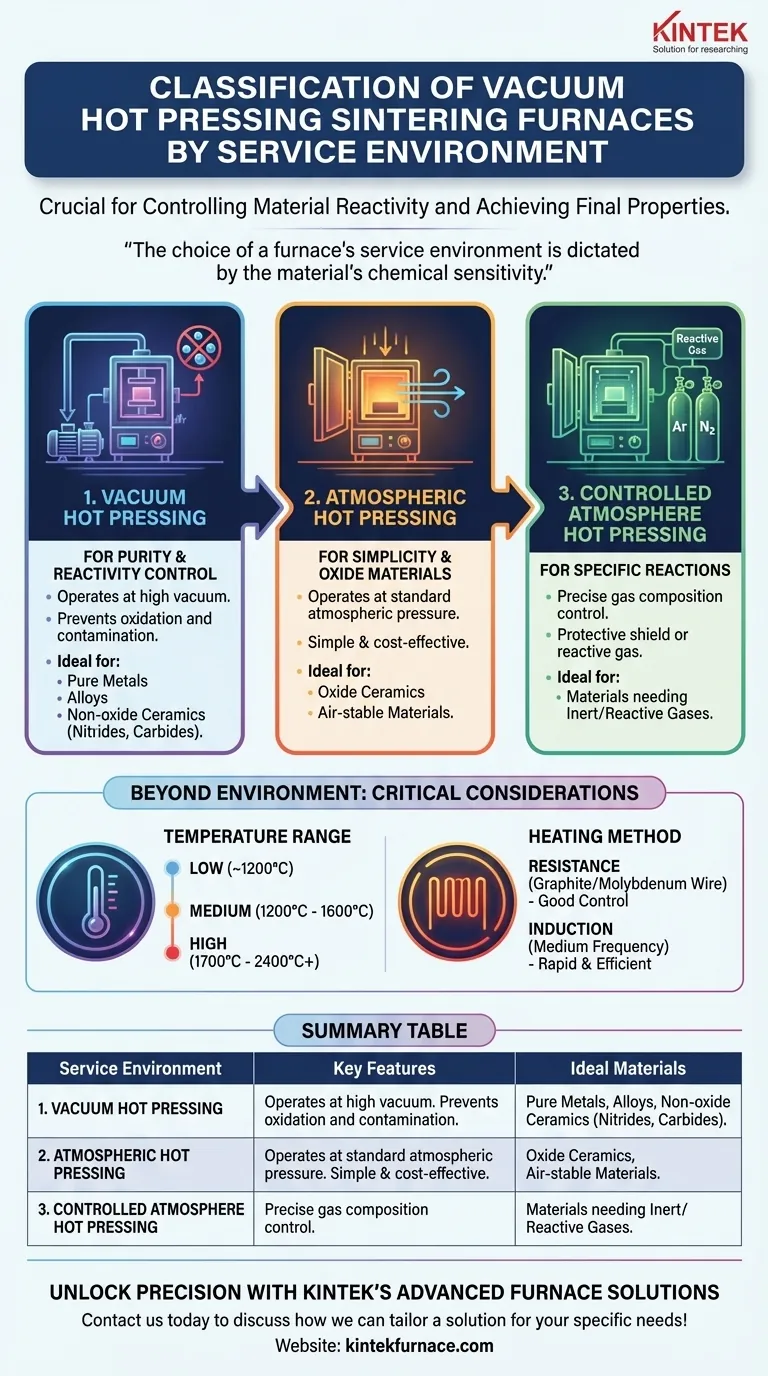

In short, vacuum hot pressing sintering furnaces are primarily classified into three types based on their service environment: vacuum, atmospheric, and controlled atmosphere. This classification is determined by the required pressure and gas composition during the sintering process, which is critical for controlling material reactivity and achieving desired final properties.

The choice of a furnace's service environment is dictated by the material's chemical sensitivity. Selecting the right environment—be it vacuum, open air, or a specific gas—is the first and most critical step in preventing unwanted reactions and ensuring the integrity of the final product.

Understanding the Three Service Environments

The "service environment" refers to the gaseous conditions inside the furnace chamber where the material is heated and pressed. Each environment serves a distinct purpose, tailored to the chemical nature of the materials being processed.

Vacuum Hot Pressing (For Purity and Reactivity Control)

This is the most controlled environment, operating at a high vacuum. It is essential for materials that are highly reactive or would be compromised by the presence of oxygen or other atmospheric gases.

By removing the atmosphere, the furnace prevents oxidation and contamination. This method is crucial for processing pure metals, alloys, and non-oxide ceramics like nitrides and carbides, where maintaining chemical purity is paramount.

Atmospheric Hot Pressing (For Simplicity and Oxide Materials)

This type of furnace operates at standard atmospheric pressure, with the material exposed to ambient air. It is the simplest and most cost-effective option.

It is primarily used for materials that are stable in air or require an oxygen-rich environment for proper sintering, such as many oxide ceramics. The lack of vacuum or gas control systems simplifies its design and operation.

Controlled Atmosphere Hot Pressing (For Specific Reactions)

This furnace is a hybrid, allowing for precise control over the gas composition inside the chamber. It can be filled with a specific inert gas (like Argon or Nitrogen) to prevent reactions or a reactive gas to facilitate a specific chemical transformation.

This environment is necessary when a process requires a protective, non-reactive shield or when a gas is part of the desired chemical reaction during sintering.

Beyond Environment: Other Critical Classifications

While the service environment is a primary classification, a true understanding requires considering temperature range and heating method. These factors work in concert with the environment to define the furnace's overall capability.

The Critical Role of Temperature Range

The maximum achievable temperature dictates which materials a furnace can process. Furnaces are generally grouped into three tiers.

- Low Temperature (Up to ~1200°C): Suitable for some metals, alloys, and specific low-temperature ceramic applications.

- Medium Temperature (~1200°C to 1600°C): Covers a wide range of common technical ceramics and specialty alloys.

- High Temperature (1700°C to 2400°C+): Required for advanced, high-performance ceramics and refractory materials with extremely high melting points.

How Heating Method Impacts Your Process

The method used to generate heat affects heating rates, temperature uniformity, and efficiency.

- Resistance Heating: The most common method. An electric current passes through a heating element (like graphite or molybdenum wire), which radiates heat. It offers good control and uniformity.

- Induction Heating: Uses electromagnetic induction to directly heat the workpiece or a susceptor. This method allows for very rapid heating rates and is highly efficient, often referred to as medium frequency heating.

Understanding the Trade-offs

Choosing a furnace involves balancing capability against complexity and cost. A more controlled environment or higher temperature range invariably leads to a more expensive and complex system.

A vacuum furnace offers the highest level of control but requires sophisticated vacuum pumps, seals, and monitoring systems, increasing both initial cost and ongoing maintenance.

An atmospheric furnace is far simpler and cheaper but is unsuitable for any material that reacts with air at high temperatures. The risk of oxidation and contamination severely limits its application.

A controlled atmosphere furnace represents a middle ground in complexity. It provides essential protection for many materials without the full cost and complexity of a high-vacuum system.

Making the Right Choice for Your Goal

Your material's chemical properties and your process goals should be the sole drivers of your decision.

- If your primary focus is processing oxygen-sensitive materials: A vacuum hot press is non-negotiable to ensure material purity and prevent oxidation.

- If your primary focus is sintering standard oxide ceramics or materials stable in air: An atmospheric hot press is the most direct and cost-effective solution.

- If your primary focus is a process requiring a specific inert or reactive gas: A controlled atmosphere furnace is the only choice to provide the necessary gaseous environment.

Understanding these core classifications empowers you to select the precise tool required to achieve your material processing objectives.

Summary Table:

| Service Environment | Key Features | Ideal Materials |

|---|---|---|

| Vacuum | High vacuum, prevents oxidation and contamination | Pure metals, alloys, non-oxide ceramics (e.g., nitrides, carbides) |

| Atmospheric | Standard air pressure, cost-effective | Oxide ceramics, air-stable materials |

| Controlled Atmosphere | Precise gas control (e.g., Argon, Nitrogen) | Materials needing protective or reactive gases |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're processing oxygen-sensitive materials or standard oxides, our furnaces ensure superior purity, efficiency, and reliability.

Contact us today to discuss how we can tailor a solution for your specific needs and elevate your material processing outcomes!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What is a hot press used for? Fabricate Dense, High-Performance Materials

- What are the applications of hot pressing? Achieve Maximum Material Performance

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties