Precise temperature control is the governing factor in defining the mechanical integrity and interface quality of Titanium-Aluminum (Ti-Al) composites during vacuum hot pressing. It acts as the regulator for atomic behavior, directly determining whether the material achieves a robust metallurgical bond or suffers from brittle failure.

Temperature regulation serves as a critical throttle for atomic diffusion; it must provide enough thermal energy to fuse the interface while strictly limiting the growth of brittle intermetallic compounds to preserve material toughness.

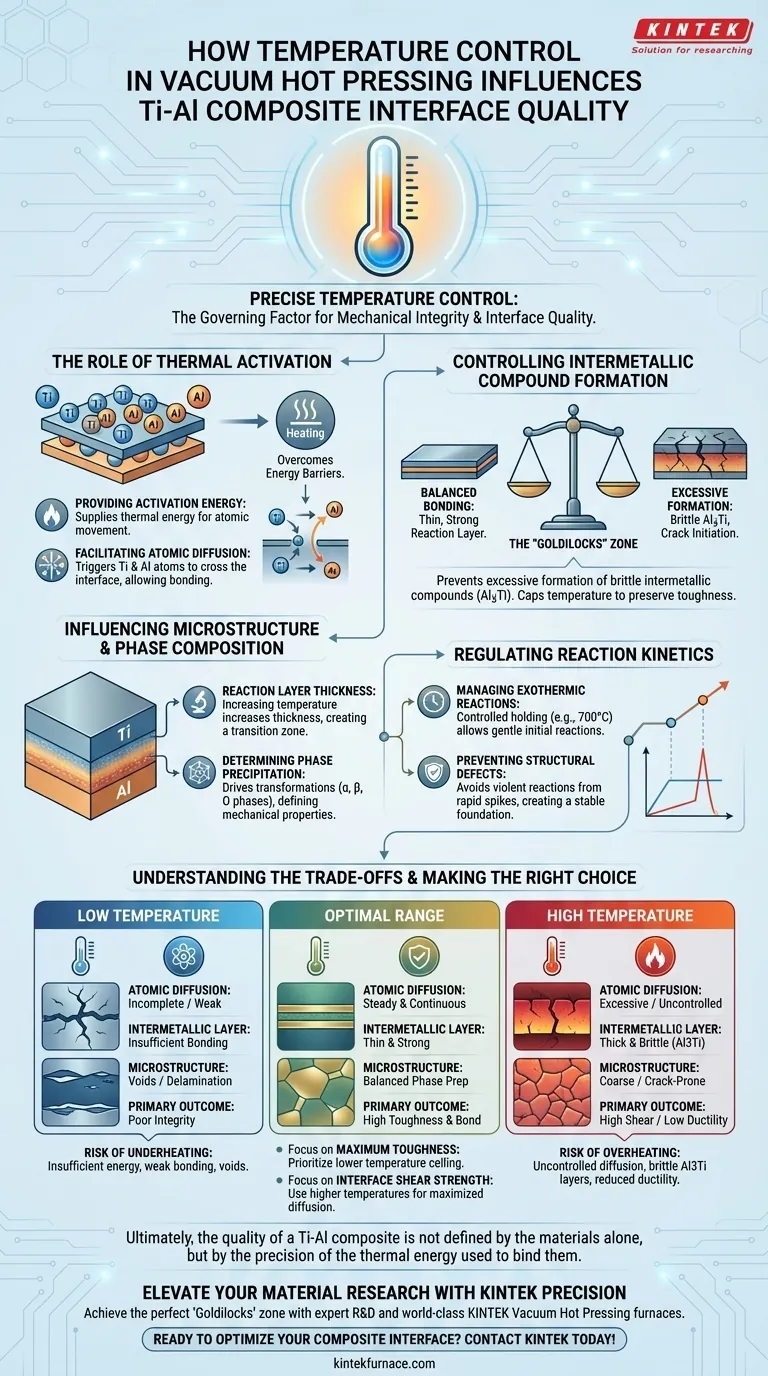

The Role of Thermal Activation

The fundamental purpose of heating in this process is to overcome energy barriers.

Providing Activation Energy

Temperature control supplies the thermal activation energy necessary for atoms to move. This energy triggers the diffusion of Titanium and Aluminum atoms across the contact interface.

Facilitating Atomic Diffusion

Without sufficient heat, atoms remain static, and the material layers will not bond. Precise regulation ensures that diffusion occurs at a rate that allows for a continuous, solid interface to form between the distinct material layers.

Controlling Intermetallic Compound Formation

The most delicate aspect of Ti-Al processing is managing the chemical reaction between the two metals.

The "Goldilocks" Zone of Bonding

The primary reference highlights that temperature must be maintained within a specific range. This prevents the excessive formation of brittle intermetallic compounds, such as Al3Ti.

Balancing Strength and Toughness

While some intermetallic formation is necessary for bonding, too much results in a fragile interface. By capping the temperature, you ensure the reaction layer remains thin enough to provide strength without compromising the composite's overall toughness.

Influencing Microstructure and Phase Composition

Beyond simple bonding, temperature dictates the internal structure of the material.

Reaction Layer Thickness

As noted in the supplementary data, increasing temperatures (e.g., from 980°C to 1050°C) directly increases the thickness of the reaction layer. This creates a transition zone where elements like Ti, Al, and Nb mix.

Determining Phase Precipitation

Temperature control drives phase transformations within the matrix. It determines the precipitation of specific phases ($\alpha, \beta, or O$), which define the final mechanical properties of the composite.

Regulating Reaction Kinetics

Temperature control is not just about reaching a set point; it is about how you get there.

Managing Exothermic Reactions

Ti-Al reactions can be exothermic (releasing heat). A controlled holding step (e.g., at 700°C) allows for initial solid-state reactions to occur gently.

preventing Structural Defects

This controlled approach avoids violent reactions that could occur if the temperature spikes too quickly. It creates a stable foundation for further densification at higher temperatures.

Understanding the Trade-offs

To achieve the ideal interface, you must navigate inherent conflicts in the heating process.

The Risk of Overheating

If the temperature is too high, diffusion accelerates uncontrollably. This leads to thick, brittle Al3Ti layers that act as crack initiation sites, drastically reducing the material's ductility.

The Risk of Underheating

If the temperature is too low, the thermal activation energy is insufficient. Atomic diffusion will be incomplete, resulting in weak interfacial bonding, voids, or delamination under stress.

Making the Right Choice for Your Goal

The optimal temperature profile depends on the specific mechanical demands of your final application.

- If your primary focus is Maximum Toughness: Prioritize a lower temperature ceiling to minimize the thickness of brittle Al3Ti intermetallic layers, even if it slightly extends processing time.

- If your primary focus is Interface Shear Strength: Use higher processing temperatures to maximize atomic diffusion and increase the reaction layer thickness, ensuring fully distinct transition zones.

Ultimately, the quality of a Ti-Al composite is not defined by the materials alone, but by the precision of the thermal energy used to bind them.

Summary Table:

| Temperature Impact | Low Temperature | Optimal Range | High Temperature |

|---|---|---|---|

| Atomic Diffusion | Incomplete / Weak | Steady & Continuous | Excessive / Uncontrolled |

| Intermetallic Layer | Insufficient Bonding | Thin & Strong | Thick & Brittle (Al3Ti) |

| Microstructure | Voids / Delamination | Balanced Phase Prep | Coarse / Crack-Prone |

| Primary Outcome | Poor Integrity | High Toughness & Bond | High Shear / Low Ductility |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect "Goldilocks" zone for Ti-Al bonding requires absolute thermal accuracy. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized Vacuum Hot Pressing furnaces tailored for advanced metallurgy.

Whether you need to minimize brittle Al3Ti layers or maximize interface shear strength, our customizable lab systems provide the stability and control your research demands.

Ready to optimize your composite interface? Contact KINTEK today to discuss your unique heating requirements!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What technical advantages does a Spark Plasma Sintering (SPS) system offer for TiB2 ceramics? Unlock Superior Strength

- How does the mechanical pressure of a Vacuum Hot Press Furnace improve composite density? Elevate Performance Today

- How does hot pressing differ from ordinary cold pressing and sintering? Unlock Superior Material Performance

- Why is high-precision temperature control critical in SiC/Al sintering? Prevent Brittle Phases and Enhance Strength

- What role do specialized mold materials play in hot pressing? Optimize Your Process with the Right Choice

- What is the difference between hot pressing and sintering? Choose the Right Process for Your Materials

- Why is a vacuum hot press furnace required for sintering CNT-Al composites? Optimize Density and Interface Bonding

- What is a hot press used for? Fabricate Dense, High-Performance Materials