At its core, a hot press is a specialized manufacturing tool that uses simultaneous high temperature and high pressure to transform powders or pre-formed materials into dense, solid parts. It is primarily used to fabricate advanced materials that are exceptionally hard and brittle, such as technical ceramics, diamond-metal composite cutting tools, and high-strength components for the aerospace industry.

The essential purpose of hot pressing is not just to shape a material, but to achieve near-total density. This process eliminates internal voids, creating finished parts with superior strength, thermal, and electrical properties that are unattainable with other consolidation methods.

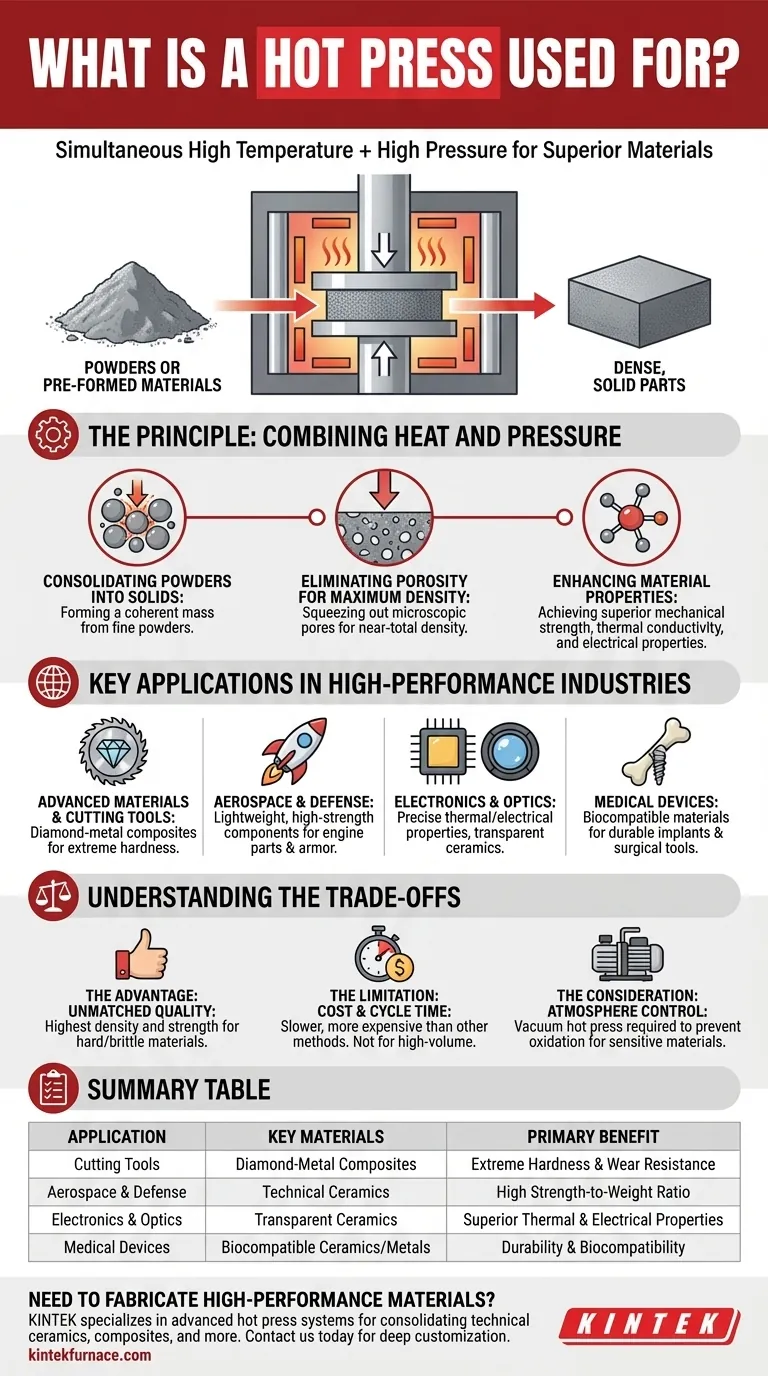

The Principle: Combining Heat and Pressure

Hot pressing is fundamentally a sintering process, but one that is significantly enhanced by the application of mechanical force. This combination fundamentally changes how materials are formed.

Consolidating Powders into Solids

Many advanced materials, like ceramics, start as fine powders. The hot press applies immense pressure to this powder while heating it, forcing the individual particles to bond together and form a solid, coherent mass.

Eliminating Porosity for Maximum Density

The key advantage of hot pressing is its ability to squeeze out the microscopic pores or voids that naturally exist between powder particles. This results in a final part that is extremely dense, often approaching the material's theoretical maximum density.

Enhancing Material Properties

This near-perfect density directly translates to superior performance. A hot-pressed ceramic or composite will have significantly higher mechanical strength, better thermal conductivity, and more predictable electrical properties compared to one made by pressure-less sintering.

Key Applications in High-Performance Industries

Because of its ability to produce superior materials, hot pressing is a critical process in industries where performance is non-negotiable.

Advanced Materials and Cutting Tools

The most common use is creating ultra-hard materials. This includes the consolidation of diamond-metal composites for industrial cutting and grinding tools and the fabrication of technical ceramics used in wear-resistant parts.

Aerospace and Defense

Hot pressing is used to produce lightweight, high-strength components that can withstand extreme conditions. These materials are essential for engine parts, armor, and structural elements where strength-to-weight ratio is paramount.

Electronics and Optics

For specialized electronics, a hot press can create components with precise thermal and electrical properties. A vacuum hot press is often used to produce transparent ceramics, which have optical properties similar to glass but are far stronger and more durable.

Medical Devices

The process is vital for fabricating biocompatible materials, such as specific types of ceramics and metal composites. These are used to create durable medical implants and surgical tools that are safe for use within the human body.

Understanding the Trade-offs

While powerful, hot pressing is not a universal solution. Its selection is a deliberate engineering choice based on specific needs and constraints.

The Advantage: Unmatched Quality

When the absolute highest density and material strength are required for a hard or brittle material, hot pressing is often the only viable option. It delivers a level of quality and performance that other processes cannot match.

The Limitation: Cost and Cycle Time

Hot pressing is generally slower and more expensive than other manufacturing methods. The equipment is complex, and the process of heating, pressing, and cooling a single part or a small batch can take a significant amount of time. It is not suited for high-volume, low-cost production.

The Consideration: Atmosphere Control

For materials that are sensitive to oxygen at high temperatures (like refractory metals or certain ceramics), a vacuum hot press is necessary. This adds another layer of complexity and cost but is essential to prevent oxidation and ensure material purity.

Making the Right Choice for Your Goal

Selecting this process depends entirely on your final objective.

- If your primary focus is maximum density and mechanical strength: Hot pressing is the ideal choice for consolidating hard powders like technical ceramics and composites.

- If your primary focus is high-performance aerospace or defense parts: This process is critical for creating lightweight components that can endure extreme stress and temperature.

- If your primary focus is specialized materials for medical or electronic use: Hot pressing provides the control needed to create biocompatible implants or components with unique thermal and optical properties.

Ultimately, you choose hot pressing when the performance and integrity of the final material cannot be compromised.

Summary Table:

| Application | Key Materials | Primary Benefit |

|---|---|---|

| Cutting Tools | Diamond-Metal Composites | Extreme Hardness & Wear Resistance |

| Aerospace & Defense | Technical Ceramics | High Strength-to-Weight Ratio |

| Electronics & Optics | Transparent Ceramics | Superior Thermal & Electrical Properties |

| Medical Devices | Biocompatible Ceramics/Metals | Durability & Biocompatibility |

Need to Fabricate High-Performance Materials?

When your project demands maximum density, superior strength, and un-compromised material integrity, the right equipment is critical. KINTEK specializes in advanced high-temperature processing solutions.

Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced hot press systems. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements for consolidating technical ceramics, composites, and other advanced materials.

Contact us today to discuss how our solutions can help you achieve your material performance goals.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What are the advantages of vacuum hot press furnaces? Achieve Superior Material Density & Purity

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What role does a high-pressure press play in the preparation of zinc sample pellets? Optimize Carbothermic Reduction