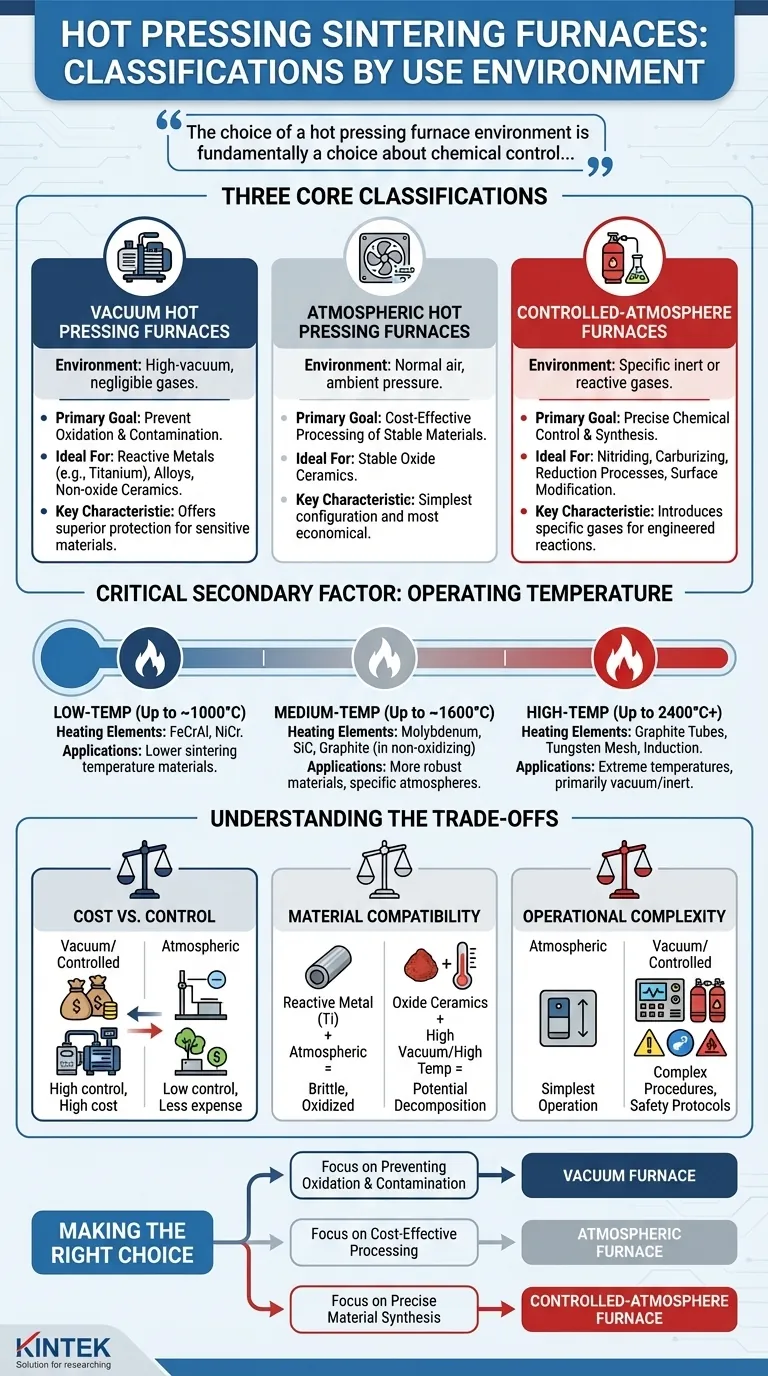

Based on the operational environment, hot pressing sintering furnaces are primarily divided into three categories: vacuum, atmospheric, and controlled-atmosphere systems. These classifications are defined by the type of gas—or lack thereof—present during the high-temperature pressing cycle, which is a critical factor in determining the final properties of the material being processed.

The choice of a hot pressing furnace environment is fundamentally a choice about chemical control. Selecting between a vacuum, open air, or a specific gas atmosphere determines whether you are trying to prevent unwanted reactions or deliberately create new ones to achieve your desired material characteristics.

The Core Classifications Explained

The environment inside the furnace directly interacts with the material at high temperatures. This interaction can be beneficial or detrimental, making the choice of atmosphere one of the most important process parameters.

Vacuum Hot Pressing Furnaces

A vacuum hot pressing furnace operates in a high-vacuum environment, meaning the atmospheric gases have been almost entirely removed.

The primary purpose is to prevent oxidation and contamination. This is essential for materials that are highly reactive with oxygen or nitrogen at elevated temperatures, such as certain metals, alloys, and non-oxide ceramics.

Atmospheric Hot Pressing Furnaces

This is the simplest configuration, where the sintering process occurs under normal atmospheric pressure, typically in ambient air.

These furnaces are used for materials that are stable in air or for processes where a degree of oxidation is either acceptable or desired. Many oxide ceramics are processed in this type of furnace due to their inherent stability.

Controlled-Atmosphere Furnaces

These systems offer the most precise level of process control by allowing a specific, engineered gas environment to be introduced and maintained.

The atmosphere can be inert (like Argon or Helium) to provide a clean, non-reactive environment similar to a vacuum, or it can be reactive (like Nitrogen or Hydrogen) to deliberately induce a chemical reaction, such as nitriding a surface or reducing an oxide.

A Critical Secondary Factor: Operating Temperature

While the environment is a primary classification, it is inextricably linked to the furnace's maximum operating temperature. The required temperature dictates the internal construction materials, which in turn must be compatible with the chosen atmosphere.

Low-Temperature Systems (Up to ~1000°C)

These furnaces typically use heating elements like iron-chromium-aluminum (FeCrAl) or nickel-chromium (NiCr) alloys. They are suitable for processing materials with lower sintering temperatures.

Medium-Temperature Systems (Up to ~1600°C)

To reach these temperatures, furnaces rely on more robust heating elements like molybdenum (Mo), silicon carbide (SiC), or graphite. The choice often depends on the required atmosphere, as graphite is unsuitable for oxidizing environments.

High-Temperature Systems (Up to 2400°C and beyond)

Achieving extreme temperatures requires specialized heating elements like graphite tubes or tungsten mesh, or non-contact methods like induction heating. These systems almost exclusively operate under vacuum or inert atmosphere to protect the heating elements themselves from rapid degradation.

Understanding the Trade-offs

Choosing a furnace environment involves balancing process requirements with practical limitations. There is no single "best" option; only the most appropriate one for a specific application.

Cost vs. Control

Vacuum and controlled-atmosphere furnaces offer superior process control but come at a significantly higher capital and operational cost. They require expensive vacuum pumps, gas delivery systems, and complex sealing mechanisms. Atmospheric furnaces are far simpler and more economical.

Material Compatibility

Using the wrong environment can catastrophically damage your material. Attempting to sinter a reactive metal like titanium in an atmospheric furnace will result in a brittle, oxidized part. Conversely, some oxides can decompose if processed under a hard vacuum at very high temperatures.

Operational Complexity

Atmospheric furnaces are the simplest to operate. Vacuum systems add significant complexity, requiring knowledge of pump-down procedures, leak rates, and pressure control. Controlled-atmosphere systems add another layer of complexity with gas flow management and safety protocols for reactive or flammable gases.

Making the Right Choice for Your Goal

Your material and your final objective should dictate your choice of furnace environment.

- If your primary focus is preventing oxidation and contamination: A vacuum hot pressing furnace is your necessary choice, especially for reactive metals, non-oxide ceramics, or advanced composites.

- If your primary focus is cost-effective processing of stable materials: An atmospheric hot pressing furnace is the most practical solution for materials like many oxide ceramics that are inert in air.

- If your primary focus is precise material synthesis or surface modification: A controlled-atmosphere furnace is essential for introducing specific gases to achieve desired chemical reactions like nitriding, carburizing, or reduction.

Ultimately, matching the furnace environment to your material's chemistry is the most critical step toward successful consolidation.

Summary Table:

| Classification | Environment Type | Key Characteristics | Ideal Applications |

|---|---|---|---|

| Vacuum | High-vacuum | Prevents oxidation and contamination | Reactive metals, non-oxide ceramics |

| Atmospheric | Normal air | Cost-effective, simple operation | Stable oxide ceramics |

| Controlled-Atmosphere | Specific gases (inert/reactive) | Precise chemical control | Nitriding, carburizing, reduction processes |

Ready to optimize your material processing with the right hot pressing sintering furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure