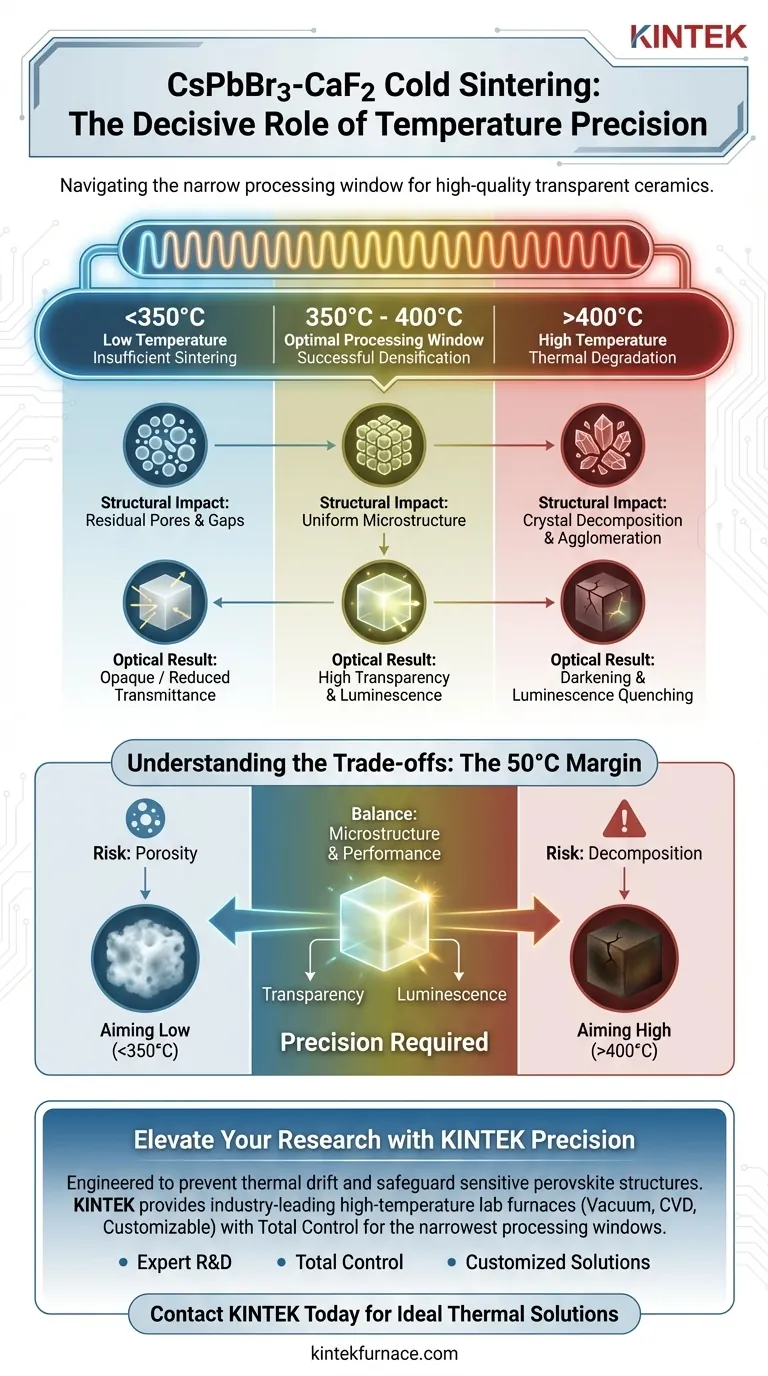

Temperature control precision is the decisive factor governing the structural integrity and optical performance of CsPbBr3-CaF2 transparent ceramics. During cold sintering, the heating system determines the final microstructure; precise control is required to navigate a narrow processing window where the material must densify without destroying the sensitive perovskite crystals.

Achieving high-quality transparent ceramics requires balancing two opposing failure modes: insufficient heat leads to opacity, while excessive heat destroys luminescence.

The Consequences of Thermal Instability

To understand why precision matters, you must look at the specific defects introduced when the temperature deviates from the optimal range.

The Impact of Low Temperatures (<350°C)

If the heating system fails to maintain sufficient heat, generally falling below 350°C, the sintering process becomes ineffective.

The primary result is insufficient densification. The ceramic particles do not bond completely, leaving gaps within the structure.

These gaps manifest as residual pores. Because these pores scatter light passing through the material, the final product suffers from significantly reduced transmittance, appearing opaque rather than transparent.

The Impact of High Temperatures (>400°C)

Conversely, if the heating system overshoots or drifts above 400°C, the chemical stability of the material is compromised.

High heat causes the thermal decomposition of the CsPbBr3 perovskite crystals. It can also trigger agglomeration, where crystals clump together in an uncontrolled manner.

The visible result of this overheating is luminescence quenching and a distinct darkening of the sample. Essentially, the material loses its ability to emit light efficiently because the active perovskite phase has been degraded.

Understanding the Trade-offs

The difficulty in cold sintering this specific composite lies in the extremely narrow margin for error.

The Narrow Processing Window

You are operating within a window of roughly 50°C (between 350°C and 400°C).

A heating system with poor precision (e.g., wide fluctuations or temperature gradients) forces a compromise.

If you aim for the lower end to be safe, you risk porosity. If you aim for the higher end to ensure density, you risk decomposition.

Balancing Microstructure and Performance

There is no middle ground where "good enough" applies.

Microstructural density is required for transparency, but chemical integrity is required for luminescence.

A system lacking precision cannot simultaneously satisfy both requirements, leading to a ceramic that is either cloudy or optically dead.

Optimizing Your Sintering Protocol

To produce high-quality CsPbBr3-CaF2 ceramics, your thermal strategy must be aligned with your specific performance goals.

- If your primary focus is Optical Transparency: You must verify that your heating profile consistently stays above 350°C to ensure full densification and eliminate light-scattering pores.

- If your primary focus is Luminescent Performance: You must implement strict thermal limits to ensure the material never exceeds 400°C, preventing the degradation of the perovskite crystals.

Ultimate quality is achieved only when the heating system is precise enough to hold the temperature firmly between these two critical thresholds.

Summary Table:

| Temperature Range | Process Outcome | Structural Impact | Optical/Luminescent Result |

|---|---|---|---|

| Low (<350°C) | Insufficient Sintering | Residual pores & gaps | Opaque/Reduced transmittance |

| Optimal (350-400°C) | Successful Densification | Uniform microstructure | High transparency & luminescence |

| High (>400°C) | Thermal Degradation | Crystal decomposition & agglomeration | Darkening & luminescence quenching |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect 50°C window for CsPbBr3-CaF2 ceramics requires more than just heat; it requires absolute thermal stability. KINTEK provides industry-leading high-temperature lab furnaces—including specialized Vacuum, CVD, and customizable systems—engineered to prevent thermal drift and safeguard your sensitive perovskite structures.

Why choose KINTEK?

- Expert R&D: Systems designed for the narrow processing windows of advanced ceramics.

- Total Control: Precision heating to eliminate porosity and prevent luminescence quenching.

- Customized Solutions: Tailored furnace configurations to meet your specific research or manufacturing scale.

Don't compromise your ceramic quality with unstable equipment. Contact KINTEK today to find the ideal thermal solution for your lab.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How are hot press furnaces involved in semiconductor manufacturing? Essential for Wafer Bonding in 3D ICs

- What role does a high-strength graphite mold play in the hot pressing and sintering of Ag-Ti2SnC? Boost Densification

- What is a vacuum hot press? Achieve Ultimate Material Purity and Density

- What advantages does an SPS furnace offer for ZnS ceramic preparation? Achieve Superior Hardness and Optical Clarity

- What are the technical advantages of using a Spark Plasma Sintering (SPS) system for Barium Titanate ceramics?

- Why is vacuum hot press sintering recommended over pressureless sintering? Achieve Peak Density for IZO Ceramic Targets

- What are the advantages of industrial SPS vs traditional sintering for SiC? Superior Density and Fine-Grain Structure

- How does the capability for long-duration temperature control in a vacuum hot pressing furnace improve ZnS ceramics?