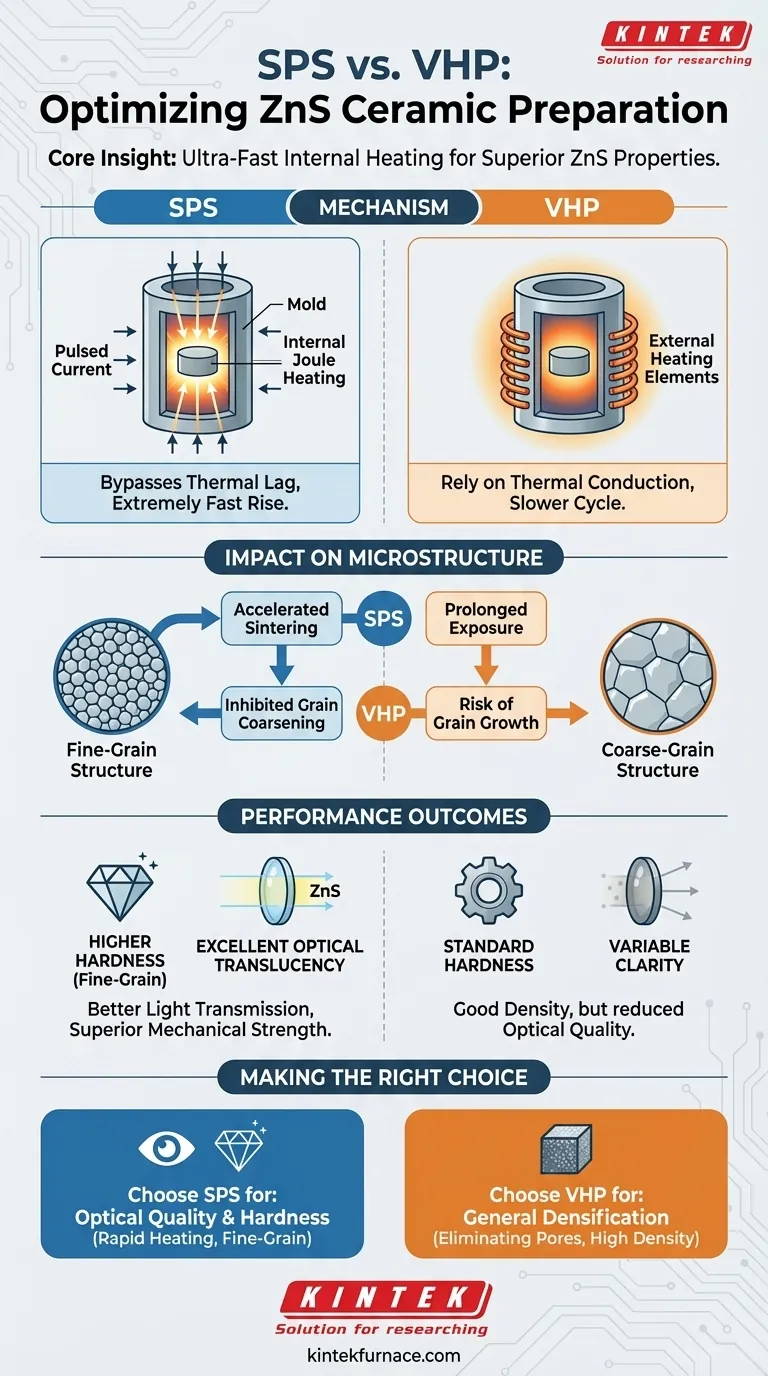

Spark Plasma Sintering (SPS) fundamentally outperforms traditional hot pressing for Zinc Sulfide (ZnS) ceramic preparation by utilizing a unique heating mechanism. While traditional methods rely on external heating elements, SPS passes pulsed current directly through the mold or sample, generating internal Joule heat. This allows for significantly faster heating rates and shorter sintering cycles, which are critical for optimizing the material's microstructure.

Core Insight: The primary advantage of SPS lies in its speed. By minimizing the time the material spends at peak temperatures, SPS effectively inhibits grain coarsening. This results in ZnS ceramics that possess a fine-grain structure, superior hardness, and excellent optical translucency that traditional methods struggle to match.

The Mechanics of Rapid Densification

Direct Joule Heating

The defining feature of an SPS furnace is the generation of heat from within the system.

Pulsed electric current is passed directly through the graphite mold and the ZnS powder compact.

This mechanism, known as Joule heating, bypasses the thermal lag associated with the external heating elements used in vacuum hot pressing.

Accelerated Sintering Cycles

Because the heat is generated internally, the temperature rises extremely quickly.

This allows the ZnS sample to reach its densification temperature in a fraction of the time required by traditional hot pressing.

The reduction in total process time is the key variable that differentiates the final material properties.

Impact on Microstructure and Performance

Inhibiting Grain Coarsening

In ceramic processing, prolonged exposure to high temperatures often leads to excessive grain growth (coarsening).

The rapid heating rate of SPS drastically reduces this thermal exposure window.

By shortening the sintering time, SPS effectively arrests grain growth before it degrades the material's structure.

Fine-Grain Structure and Hardness

The direct result of inhibited coarsening is a ceramic with a fine-grain microstructure.

According to the Hall-Petch relationship, finer grain sizes generally correlate with increased mechanical strength.

Consequently, ZnS ceramics prepared via SPS exhibit significantly higher hardness compared to those processed via slower methods.

Superior Optical Translucency

For ZnS, which is often used in optical applications, microstructure determines performance.

Large, coarse grains can scatter light, reducing transparency.

The fine-grain structure achieved through SPS ensures better light transmission, yielding excellent optical translucency.

Understanding the Trade-offs

The Role of Vacuum Hot Pressing

While SPS offers speed and microstructural benefits for ZnS, it is important to acknowledge the capabilities of traditional Vacuum Hot Pressing (VHP).

As noted in supplementary contexts, VHP effectively utilizes pressure to eliminate pore defects and achieve high densities (up to 99.1%).

Speed vs. Stability

VHP is capable of inhibiting abnormal grain growth compared to pressureless sintering and is highly effective for materials like lithium niobate.

However, for ZnS specifically, the ultra-fast heating of SPS provides a distinct edge in retaining the finest possible grain size, which is critical for optical quality.

Making the Right Choice for Your Goal

To select the appropriate sintering technology for your ZnS application, consider the following performance priorities:

- If your primary focus is Optical Quality and Hardness: Choose Spark Plasma Sintering (SPS) to leverage rapid heating that maintains a fine-grain structure and maximizes translucency.

- If your primary focus is General Densification: Traditional Vacuum Hot Pressing remains a viable option for eliminating pores and achieving high density, particularly if ultra-fast cycle times are not critical.

For high-performance ZnS ceramics where optical clarity and mechanical durability are paramount, SPS provides the definitive technological advantage.

Summary Table:

| Feature | Spark Plasma Sintering (SPS) | Vacuum Hot Pressing (VHP) |

|---|---|---|

| Heating Mechanism | Internal Joule Heating (Pulsed Current) | External Heating Elements |

| Sintering Speed | Ultra-Fast / Short Cycles | Slow / Long Cycles |

| Grain Control | Effectively Inhibits Coarsening | Risk of Grain Growth |

| Mechanical Properties | Higher Hardness (Fine-Grain) | Standard Hardness |

| Optical Performance | Excellent Translucency | Good Density, Variable Clarity |

Elevate Your Material Research with KINTEK

Unlock the full potential of your advanced ceramics with our precision-engineered sintering solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers state-of-the-art SPS, Vacuum Hot Pressing, CVD systems, and high-temperature lab furnaces—all fully customizable to meet your unique processing requirements.

Whether you are aiming for superior optical translucency in ZnS or high-density structural ceramics, our technical team is ready to provide the specialized equipment you need for success. Contact us today to optimize your lab's performance!

Visual Guide

Related Products

- Spark Plasma Sintering SPS Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What core role does a vacuum hot press furnace play in the densification process of copper-carbon nanotube composites? Achieve High-Performance Cu-CNT Materials

- How does hot pressing compare to hot isostatic pressing (HIP)? Choose the Right Process for Your Materials

- How to maintain a vacuum machine? Ensure long-term reliability and peak performance

- What are the advantages of industrial SPS vs traditional sintering for SiC? Superior Density and Fine-Grain Structure

- What role do specialized mold materials play in hot pressing? Optimize Your Process with the Right Choice

- How does hot pressing improve mechanical properties of materials? Achieve Superior Strength and Durability

- What are the primary functions of a Vacuum Hot Press Furnace (VHP)? Master In-Situ Al3Ti/Al Composite Synthesis

- What is hot pressing and what does it involve? Unlock Superior Material Density and Strength