In the hot pressing and sintering of Ag-Ti2SnC composites, the high-strength graphite mold acts as the critical interface between the processing equipment and the material, serving simultaneously as a geometric forming container and a medium for pressure transmission. Its primary function is to maintain structural rigidity while transferring mechanical force to the powder mixture at elevated temperatures, ensuring the transformation from loose particles to a solid bulk material.

By withstanding pressures of 30 MPa at temperatures up to 700°C, the graphite mold enables the full densification of the composite. This thermal-mechanical stability is the deciding factor in achieving high relative density and minimizing porosity in the final product.

Ensuring Structural Integrity Under Stress

To achieve a high-quality composite, the processing environment must be rigorously controlled. The graphite mold provides the physical stability required for this harsh environment.

The Role of Physical Containment

The mold serves as the forming vessel that defines the shape and dimensional accuracy of the sample. It constrains the Ag-Ti2SnC powder, preventing lateral expansion while directing applied forces axially.

Withstanding High-Temperature Pressure

Unlike metallic molds that may soften or deform under heat, high-strength graphite retains excellent mechanical properties at sintering temperatures.

For Ag-Ti2SnC composites, the mold effectively withstands stable pressures of 30 MPa at 700°C. This resistance to deformation is vital for maintaining the correct geometry throughout the sintering cycle.

Facilitating the Densification Process

Beyond containment, the mold plays an active role in the kinetics of sintering, directly influencing the density and quality of the composite.

Efficient Pressure Transmission

The mold acts as the transmission medium, converting the force from the hydraulic press into effective pressure on the powder.

This pressure rearranges the particles and promotes the flow of the silver (Ag) matrix around the Ti2SnC reinforcement. This mechanism is essential for eliminating internal voids and achieving full densification.

Thermal Conductivity and Uniformity

Graphite possesses excellent thermal conductivity, which allows it to transfer heat uniformly from the heating elements to the sample.

Uniform heating prevents thermal gradients within the Ag-Ti2SnC mixture. This ensures that the silver matrix sinters evenly across the entire volume, preventing localized defects or warping.

Operational Considerations and Trade-offs

While high-strength graphite is the material of choice, working with silver-based composites requires specific handling to preserve both the sample and the equipment.

Managing Chemical Adhesion

At sintering temperatures, metallic silver (Ag) can soften or melt, creating a risk of infiltration into the porous graphite or adhesion to the mold walls.

Direct contact between the Ag-Ti2SnC powder and the mold can lead to severe sticking. This not only damages the surface quality of the composite but can also degrade or destroy the expensive graphite mold during removal.

The Necessity of Isolation Layers

To mitigate adhesion, graphite carbon paper is often used as an isolation layer between the powder and the inner wall of the mold.

This sacrificial layer prevents molten silver from infiltrating the mold. It facilitates easy demolding, ensures a smooth surface finish on the sample, and significantly extends the service life of the graphite components.

Optimizing Your Fabrication Strategy

The success of your sintering process depends on how well you utilize the mold's capabilities while mitigating its limitations.

- If your primary focus is Maximum Density: Ensure your mold design accounts for the specific thermal expansion of graphite to maintain constant pressure (30 MPa) without binding during the cooling phase.

- If your primary focus is Mold Longevity and Surface Finish: Strictly utilize graphite carbon paper liners to prevent Ag infiltration, which protects the mold's geometry for repeated use.

The high-strength graphite mold is not merely a passive container; it is the active mechanical vessel that enables the synthesis of dense, high-performance Ag-Ti2SnC composites.

Summary Table:

| Key Role | Specific Function | Performance Benefit |

|---|---|---|

| Pressure Transmission | Transfers 30 MPa axial force to powder | Minimizes porosity and ensures full densification |

| Thermal Stability | Maintains rigidity at 700°C | Prevents deformation and ensures dimensional accuracy |

| Thermal Conductivity | Distributes heat uniformly | Eliminates thermal gradients and localized defects |

| Geometric Forming | Constrains Ag-Ti2SnC powder | Maintains final shape and structural integrity |

Maximize Your Material Performance with KINTEK

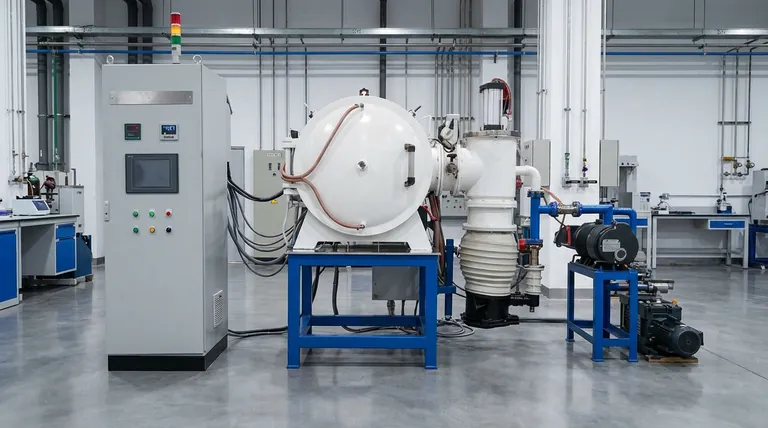

Achieving full densification in Ag-Ti2SnC composites requires precision tools that can withstand extreme thermal-mechanical stress. KINTEK provides high-performance lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—specifically designed to meet these rigorous standards.

Backed by expert R&D and manufacturing, our equipment is fully customizable to solve your unique sintering and hot-pressing challenges. Whether you are optimizing density or extending mold longevity, our technical team is ready to assist.

Contact KINTEK Today to Optimize Your Sintering Process

References

- Xiaochen Huang, Hongyu Chen. Influence of Ti <sub>2</sub> SnC content on arc erosion resistance in Ag–Ti <sub>2</sub> SnC composites. DOI: 10.1515/secm-2022-0244

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How do the temperature and pressure conditions in a vacuum hot-pressing furnace facilitate the densification of AMC?

- Why is a hot pressing furnace equipped with a vacuum system necessary for sintering high-entropy alloy coatings? Ensure Purity, Density, and Superior Performance

- What are the technical advantages of Spark Plasma Sintering (SPS) for maraging steel? Achieve Rapid Densification

- How does the vacuum environment facilitate the densification of ZnS ceramics? Unlock High-Performance Liquid Sintering

- What is a hot press machine used for? From custom apparel to aerospace components

- What are the advantages of SPS over hot pressing for high-entropy alloys? Achieve Superior Density and Microstructure

- How do vacuum and argon affect Ag-Ti2SnC composites? Optimize Sintering with Industrial Hot-Pressing Furnaces

- What makes the sintering process during hot pressing unbalanced? Speed vs. Microstructural Equilibrium