Spark Plasma Sintering (SPS) offers a distinct technical advantage for maraging steel by utilizing pulsed direct current and mechanical pressure to achieve rapid densification. This process generates extremely high heating rates with very short holding times, effectively inhibiting grain growth and preserving the fine microstructure necessary for superior mechanical properties.

By bypassing the long thermal cycles of conventional sintering, SPS enables the creation of "self-composite" structures where strength and plasticity can be precisely tuned without melting the material.

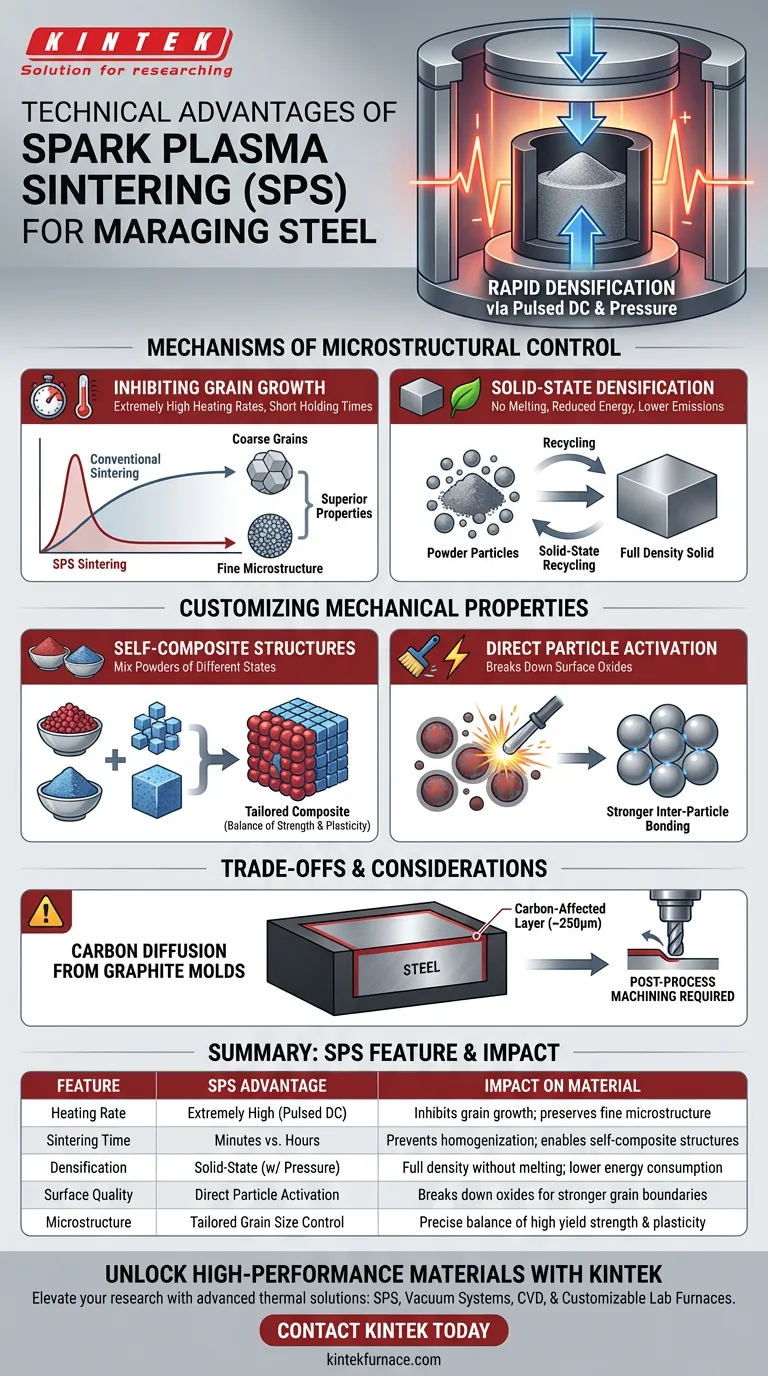

Mechanisms of Microstructural Control

Inhibiting Grain Growth

The primary advantage of SPS is the speed at which it operates. Because the pulsed current is applied directly through the powder particles, the system achieves extremely high heating rates.

This rapid heating, combined with short holding times, significantly limits the window for grain coarsening. The result is a fine-grained microstructure that retains superior mechanical strength compared to materials processed via slower, conventional sintering methods.

Solid-State Densification

SPS operates as a solid-state recycling and manufacturing method. Unlike melting processes, SPS avoids the complete phase change of the metal.

By maintaining the material in a solid state, you can achieve full densification within minutes while partially preserving the original fine microstructures of the starting powder or chips. This also results in reduced energy consumption and lower carbon emissions.

Customizing Mechanical Properties

Creating Self-Composite Structures

A unique capability of SPS is the facilitation of self-composite structures. Engineers can mix powders of different pre-treatment states before sintering.

Because the process is fast and precise, these distinct states are not homogenized into a single average structure. Instead, they form a composite within the single material, allowing for a tailored balance between high strength and plasticity.

Direct Particle Activation

The application of pulsed current and pressure helps break down surface oxides and impurities on the powder particles. This leads to cleaner grain boundaries and stronger inter-particle bonding, which is critical for the structural integrity of high-performance alloys like maraging steel.

Understanding the Trade-offs

Carbon Diffusion from Graphite Molds

While technically superior in densification, the use of graphite molds in SPS introduces a specific challenge for maraging steel. The high-temperature pressing environment facilitates carbon diffusion from the mold into the steel's surface.

The Necessity of Post-Process Machining

This diffusion typically results in a carbon-affected layer approximately 250 micrometers deep. To ensure that mechanical testing accurately reflects the properties of the maraging steel matrix—rather than this surface artifact—this layer must be removed via machining or grinding after the sintering process.

Making the Right Choice for Your Application

- If your primary focus is maximizing yield strength: Leverage the rapid heating rates of SPS to inhibit grain growth and maintain a fine microstructure.

- If your primary focus is balancing ductility and hardness: Utilize the "self-composite" technique by mixing powders of varying pre-treatment states to tune the material's plasticity.

- If your primary focus is dimensional precision: Plan for a post-sintering machining allowance of at least 250 micrometers to remove the carbon-diffusion layer caused by the graphite tooling.

SPS converts the challenge of sintering complex alloys into an opportunity for precise microstructural engineering, provided the surface interaction with tooling is managed correctly.

Summary Table:

| Technical Feature | SPS Advantage for Maraging Steel | Impact on Material |

|---|---|---|

| Heating Rate | Extremely high via pulsed DC | Inhibits grain growth; preserves fine microstructure |

| Sintering Time | Minutes vs. hours | Prevents homogenization; enables self-composite structures |

| Densification | Solid-state under mechanical pressure | Full density without melting; lower energy consumption |

| Surface Quality | Direct particle activation | Breaks down oxides for stronger grain boundaries |

| Microstructure | Tailored grain size control | Precise balance of high yield strength and plasticity |

Unlock High-Performance Materials with KINTEK

Elevate your research and production with KINTEK’s advanced thermal solutions. Whether you are working with maraging steel or complex alloys, our expertise in SPS, Vacuum systems, CVD, and customizable lab high-temp furnaces ensures you achieve precise microstructural control and superior material properties.

Backed by industry-leading R&D and manufacturing, we provide the tools you need for rapid densification and customized material performance. Contact KINTEK today to discuss your unique project requirements and let us build the perfect furnace for your laboratory’s needs.

Visual Guide

References

- Innovative Powder Pre-Treatment Strategies for Enhancing Maraging Steel Performance. DOI: 10.3390/ma18020437

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Spark Plasma Sintering SPS Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What core role does a vacuum hot press furnace play in the densification process of copper-carbon nanotube composites? Achieve High-Performance Cu-CNT Materials

- Why must vacuum hot press pressure be adjusted for SiC fiber spacing? Optimize Titanium Matrix Composites

- What are the advantages of using a VHP furnace over CVD for ZnS? Boost Strength and Efficiency with Vacuum Hot Pressing

- What is the primary function of a hot-pressing furnace in SiC bicrystal synthesis? Achieve Precision Atomic Bonding

- What is the hot pressing process in material densification? Achieve Superior Density for Advanced Materials

- What key role does a vacuum hot pressing furnace play in ADSC alloys? Achieve Near-Theoretical Density & Purity

- What role does the mechanical pressure applied by the hot pressing mechanism play? Optimize Densification Now

- What is activated hot sintering and its advantages? Achieve Superior Material Densification Efficiently