In materials science and manufacturing, Vacuum Hot Pressing (VHP) is a high-performance consolidation process used to transform powders into dense, solid components. It is specifically employed to fabricate high-purity ceramic and powder metal targets by simultaneously applying high temperature and uniaxial pressure within a vacuum. This method is critical for materials that cannot achieve full density through conventional sintering alone, preventing issues like porosity and internal defects.

The core challenge in creating advanced targets is that simple heating often fails to eliminate all the tiny voids between powder particles. Vacuum Hot Pressing solves this by using external pressure to physically squeeze these voids shut during heating, resulting in a dense, uniform material with superior mechanical properties.

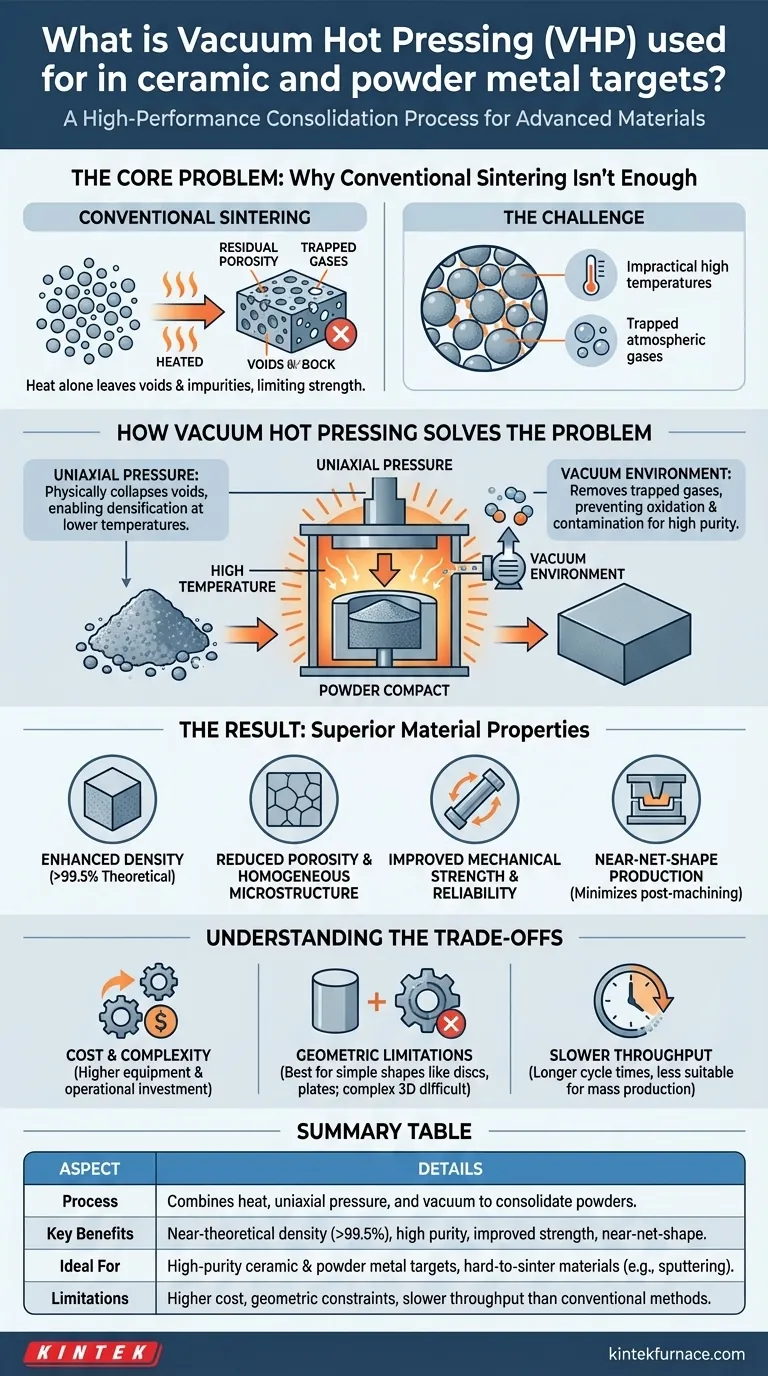

The Core Problem: Why Conventional Sintering Isn't Enough

To understand the value of Vacuum Hot Pressing, you must first understand the limitations of standard sintering, which is the process of compacting and heating a powder below its melting point.

The Challenge of Inherent Porosity

Powder materials, even when compacted, contain a network of tiny voids or pores between the particles. While sintering encourages the particles to bond and shrink, it often leaves behind residual porosity.

These leftover pores act as stress concentration points, severely degrading the material's mechanical strength and performance.

The Limits of Temperature

For some advanced ceramics and refractory metals, the temperature required to achieve full density via sintering is impractically high. Such extreme heat can cause unwanted grain growth, material decomposition, or damage to the processing equipment.

The Impact of Trapped Gases

When sintering in air, atmospheric gases like oxygen and nitrogen can become trapped within the material's pores. This not only prevents the pores from fully closing but also introduces impurities that contaminate the final product and alter its properties.

How Vacuum Hot Pressing Solves the Problem

Vacuum Hot Pressing directly addresses the failures of conventional sintering by adding two critical elements: external pressure and a vacuum environment.

The Role of Uniaxial Pressure

The defining feature of hot pressing is the application of continuous, directional pressure from a press. This force physically collapses the voids between powder particles.

This mechanical assistance allows for full densification at significantly lower temperatures and shorter times compared to pressureless sintering.

The Benefit of a Vacuum Environment

Performing the process in a vacuum removes the atmospheric gases that would otherwise become trapped. This prevents oxidation and contamination, which is essential for producing the high-purity targets required for applications like physical vapor deposition (sputtering).

The Result: Superior Material Properties

The combination of heat, pressure, and vacuum produces a final product with measurable advantages.

- Enhanced Density: VHP consistently achieves near-theoretical density (typically >99.5%).

- Reduced Porosity: The physical compaction virtually eliminates voids, leading to a homogenous microstructure.

- Improved Mechanical Strength: A dense, pore-free structure is significantly stronger and more reliable than a porous one.

- Near-Net-Shape Production: The process forms parts that are very close to their final dimensions, minimizing the need for costly and difficult post-machining of hard materials.

Understanding the Trade-offs

While powerful, Vacuum Hot Pressing is not a universal solution. Its benefits come with specific constraints that must be considered.

Cost and Complexity

VHP equipment is significantly more expensive and complex to operate than a standard sintering furnace. The need for a robust press, a high-vacuum system, and precision controls increases both capital investment and operational costs.

Geometric Limitations

Because pressure is applied in a single direction (uniaxially), VHP is best suited for producing relatively simple geometries like discs, plates, and cylinders. Fabricating parts with complex 3D shapes is extremely difficult with this method.

Slower Throughput

The process cycle—which includes loading, pumping down to vacuum, heating, pressing, and cooling—is inherently slower than many high-volume manufacturing techniques. This makes it less suitable for mass production and more appropriate for high-value components.

Making the Right Choice for Your Goal

Selecting the right consolidation method depends entirely on your material's characteristics and the performance requirements of the final component.

- If your primary focus is achieving maximum density and material integrity: VHP is the superior choice for any powder material that is difficult to sinter, especially for demanding applications like sputtering targets or high-strength structural ceramics.

- If your primary focus is high-volume production of non-critical parts: A conventional press-and-sinter process is far more cost-effective, assuming the material can reach acceptable performance levels without full densification.

- If your primary focus is creating complex, three-dimensional shapes: Alternative methods like powder injection molding (PIM) or additive manufacturing should be investigated, though they come with their own distinct property and cost profiles.

Ultimately, choosing Vacuum Hot Pressing is a strategic decision to prioritize final material quality and performance above all other considerations.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Combines heat, uniaxial pressure, and vacuum to consolidate powders into dense solids. |

| Key Benefits | Near-theoretical density (>99.5%), reduced porosity, high purity, improved strength, near-net-shape production. |

| Ideal For | High-purity ceramic and powder metal targets, materials difficult to sinter, applications like sputtering. |

| Limitations | Higher cost, geometric constraints (simple shapes), slower throughput compared to conventional methods. |

Elevate your material performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more. Our strong deep customization capability ensures precise solutions for your unique experimental needs, such as achieving superior density in ceramic and metal targets. Contact us today to discuss how we can optimize your consolidation processes and deliver reliable, high-quality results!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the advantages of hot pressing? Achieve Maximum Density and Superior Material Properties

- What is a hot press used for? Fabricate Dense, High-Performance Materials

- What is vacuum hot pressing? Achieve Superior Material Strength and Purity

- How do temperature, pressure, and vacuum affect material bonding and microstructure in vacuum hot pressing? Optimize for High-Performance Materials

- What are the applications of hot pressing? Achieve Maximum Material Performance