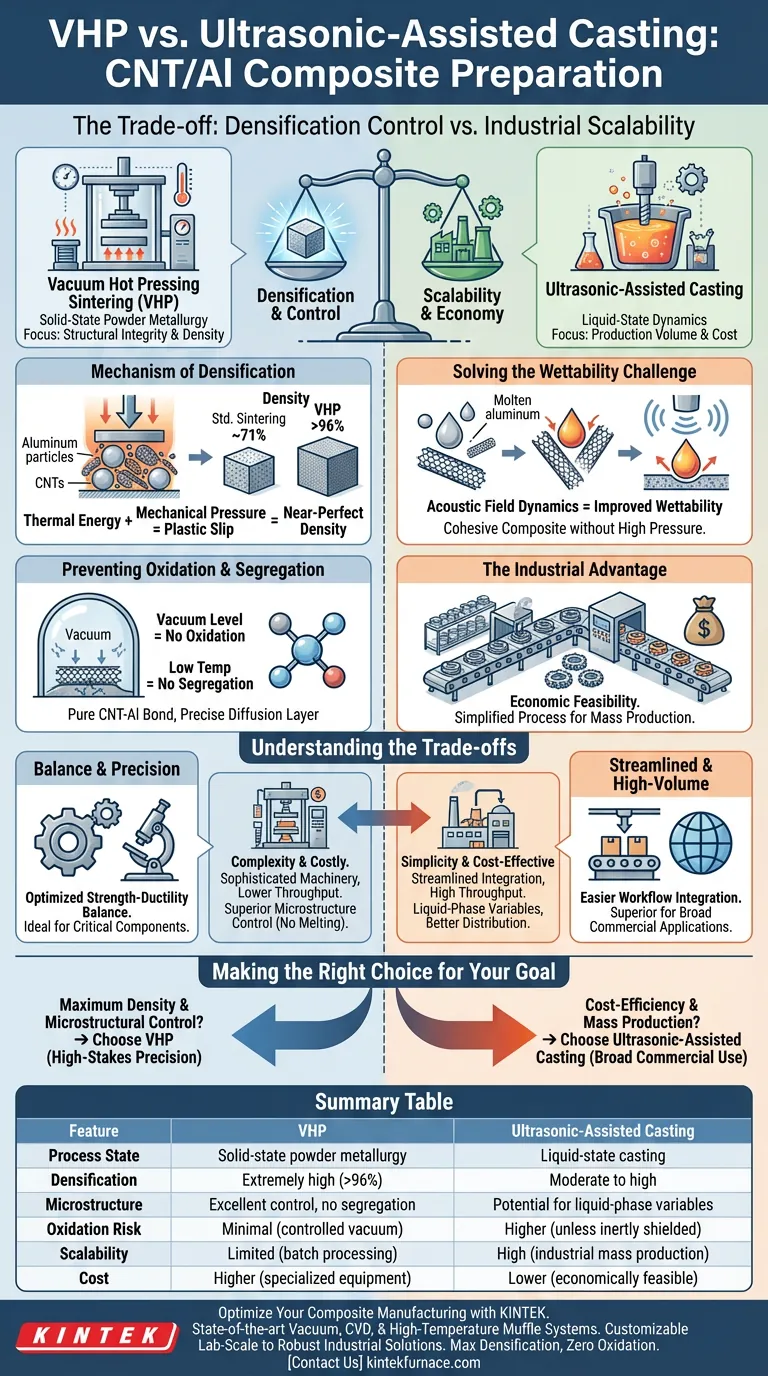

The primary distinction lies in the trade-off between densification control and industrial scalability. Vacuum hot pressing sintering (VHP) is a powder metallurgy process that achieves superior densification and prevents oxidation through a controlled vacuum environment, making it precise but costly. Conversely, ultrasonic-assisted casting leverages acoustic field dynamics to solve wettability issues, offering a much more cost-effective and scalable pathway for mass production.

The core divergence is that VHP excels at achieving near-perfect density and controlling microstructural interfaces in a solid state, while ultrasonic-assisted casting solves the economic and scalability challenges required for industrial manufacturing.

Achieving High Density with Vacuum Hot Pressing

Vacuum hot pressing is a "solid-state" technique. It prioritizes the structural integrity of the composite by avoiding the liquid phase of the metal matrix.

The Mechanism of Densification

VHP integrates thermal energy and mechanical pressure within a single vacuum chamber. By applying pressure simultaneously with heat, the process induces plastic slip in the aluminum alloy particles.

This mechanical force rearranges the reinforcement particles (CNTs), forcibly excluding internal pores. While standard vacuum sintering might only achieve ~71% density, VHP can drive composite density to over 96%, approaching a fully dense state.

Preventing Oxidation and Segregation

Because VHP operates at temperatures far below the metal's melting point, it avoids composition segregation that often occurs during melting.

Furthermore, the controlled vacuum level is critical for aluminum composites. It prevents interface oxidation, ensuring that the bond between the Carbon Nanotubes (CNTs) and the Aluminum (Al) matrix remains pure and strong.

Balancing Material Properties

This method allows engineers to balance strength and ductility precisely. By controlling the temperature and pressure, one can manage the diffusion layer thickness, optimizing the mechanical performance of the final composite.

Scalability via Ultrasonic-Assisted Casting

Ultrasonic-assisted casting takes a different approach, focusing on the dynamics of the liquid metal to facilitate production volume.

Solving the Wettability Challenge

One of the hardest parts of combining CNTs with aluminum is "wettability"—getting the liquid metal to stick to the carbon nanotubes.

This method utilizes acoustic field dynamics. The ultrasonic vibrations improve the wetting contact between the molten aluminum and the nanotubes, ensuring a cohesive composite without the need for high-pressure compaction.

The Industrial Advantage

The primary benefit of this method is economic feasibility. The production process is significantly less complex than powder metallurgy.

It provides a scalable industrial pathway, allowing for the creation of high-performance composite materials without the extreme costs associated with vacuum chambers and high-pressure hydraulic systems.

Understanding the Trade-offs

While both methods aim to create high-performance CNT/Al composites, they serve different engineering constraints.

Complexity vs. Simplicity

VHP is inherently complex. It requires sophisticated machinery to maintain a vacuum while applying tons of pressure. This complexity translates to higher operational costs and lower production throughput.

Ultrasonic casting is streamlined. It integrates into existing casting workflows more easily, making it the superior choice for high-volume manufacturing.

Solid-State vs. Liquid-State Limitations

VHP offers superior control over the microstructure because the metal never melts. This is ideal for critical components where segregation cannot be tolerated.

However, casting involves a liquid phase. While ultrasonic assistance improves distribution, managing the physics of molten metal introduces variables that are less present in the solid-state VHP process.

Making the Right Choice for Your Goal

To select the appropriate manufacturing method for your CNT/Al composite application:

- If your primary focus is maximum density and microstructural control: Choose Vacuum Hot Pressing. The ability to exclude pores via mechanical pressure and prevent oxidation in a vacuum ensures the highest possible material integrity, despite the higher cost.

- If your primary focus is cost-efficiency and mass production: Choose Ultrasonic-Assisted Casting. The use of acoustic fields resolves the critical wetting issue while maintaining a process simple enough for scalable industrial application.

Ultimately, use VHP for high-stakes, precision components, and reserve ultrasonic casting for broader commercial applications where volume is key.

Summary Table:

| Feature | Vacuum Hot Pressing (VHP) | Ultrasonic-Assisted Casting |

|---|---|---|

| Process State | Solid-state powder metallurgy | Liquid-state casting |

| Densification | Extremely high (>96% density) | Moderate to high |

| Microstructure | Excellent control; no segregation | Potential for liquid-phase variables |

| Oxidation Risk | Minimal (controlled vacuum) | Higher (unless inertly shielded) |

| Scalability | Limited; batch processing | High; industrial mass production |

| Cost | Higher (specialized equipment) | Lower (economically feasible) |

Optimize Your Composite Manufacturing with KINTEK

Are you deciding between the precision of Vacuum Hot Pressing or the scalability of casting for your advanced materials? Backed by expert R&D and manufacturing, KINTEK offers state-of-the-art Vacuum, CVD, and High-Temperature Muffle Systems designed to deliver the exact microstructural control your CNT/Al composites require.

Whether you need customizable lab-scale furnaces or robust industrial vacuum systems, our solutions ensure maximum densification and zero oxidation. Contact us today to discuss your unique technical needs and see how our expertise can drive your production efficiency forward.

Visual Guide

References

- X.H. Dong, Hong Yan. Microstructure and Mechanical Properties of Cu-CoatedCarbon-Nanotubes-Reinforced Aluminum Matrix Composites Fabricated by Ultrasonic-Assisted Casting. DOI: 10.3390/met14030265

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is precise temperature control in a Vacuum Hot Pressing furnace crucial for AZ31/UCF/AZ31 composites?

- In which fields is hot pressing technology applied? Essential for Aerospace, Defense, and Advanced Manufacturing

- What role does mechanical pressure play in hot press diffusion? Master Microlaminated Composite Bonding

- What is the role of a high-strength graphite die in the vacuum hot press sintering of SiC ceramics? Essential Functions

- What is the application of hot press furnaces in ceramic processing? Achieve Superior Density and Strength

- What are the key advantages of vacuum hot press furnaces compared to conventional furnaces? Achieve Superior Purity and Control

- What is the hot pressing process in material densification? Achieve Superior Density for Advanced Materials

- How does vacuum hot pressing benefit powder metallurgy? Achieve Dense, High-Performance Materials