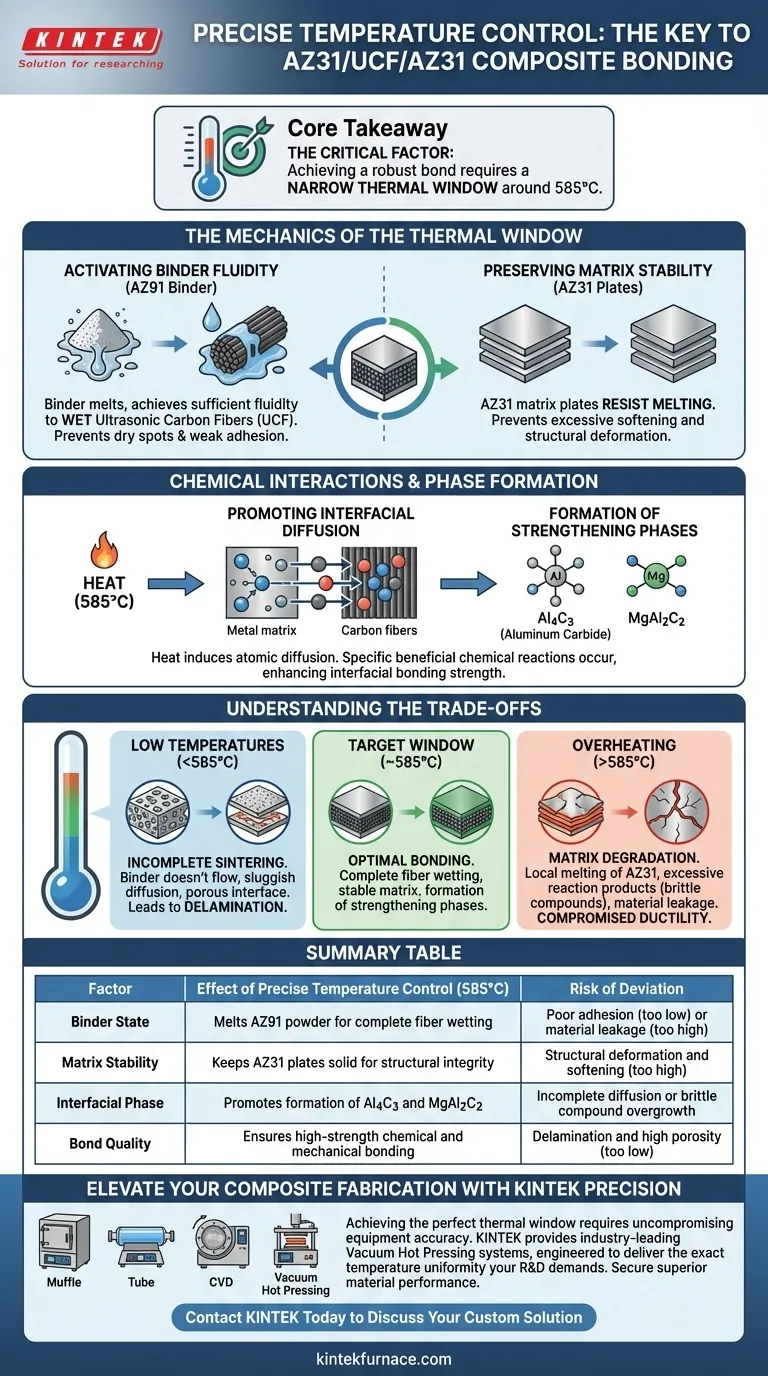

Precise temperature control is the critical factor that governs the transition from loose components to a unified composite in Vacuum Hot Pressing. For AZ31/UCF/AZ31 composites, specifically, this control dictates whether the binder material can effectively "glue" the carbon fibers to the magnesium alloy matrix without destroying the matrix itself.

Core Takeaway Achieving a robust bond requires a narrow thermal window, specifically around 585°C for this material system. This temperature is the precise point where the AZ91 binder melts sufficiently to wet the carbon fibers, while the AZ31 matrix remains solid enough to maintain structural integrity, allowing for the formation of essential strengthening phases like Al4C3 and MgAl2C2.

The Mechanics of the Thermal Window

The Vacuum Hot Pressing (VHP) process relies on finding a specific thermal equilibrium. You are not simply heating material; you are managing two distinct physical states simultaneously within the same chamber.

Activating the Binder Fluidity

The binder, typically AZ91 powder, serves as the active adhesive agent. It must reach a temperature where it fully melts and achieves sufficient fluidity.

Without this liquidity, the binder cannot penetrate the fiber bundles. It fails to "wet" the Ultrasonic Carbon Fibers (UCF), resulting in dry spots and weak adhesion.

Preserving Matrix Stability

While the binder melts, the primary structural component—the AZ31 plates—must resist melting.

Precise control prevents the AZ31 matrix from softening excessively. If the temperature drifts too high, the plates lose their geometric stability, leading to structural deformation of the final composite part.

Chemical Interactions and Phase Formation

Beyond physical wetting, temperature control drives the chemical reactions necessary for a high-strength interface. The bond is not merely mechanical; it is chemical.

Promoting Interfacial Diffusion

The heat induces atomic diffusion between the metal matrix and the carbon fibers. This diffusion is the precursor to forming a permanent bond between dissimilar materials.

Formation of Strengthening Phases

At the target temperature (e.g., 585°C), specific chemical reactions occur that are beneficial to this specific composite.

The primary reference indicates that accurate heat control promotes the formation of interfacial phases such as Al4C3 (Aluminum Carbide) and MgAl2C2. Contrary to some systems where carbides are strictly avoided, here these phases enhance the interfacial bonding strength.

Understanding the Trade-offs

In VHP processes, the margin for error is often negligible. Understanding the consequences of deviating from the setpoint is as important as knowing the target.

The Consequence of Low Temperatures

If the furnace runs cooler than the target, sintering remains incomplete. The binder does not flow, diffusion is sluggish, and the interface remains porous. This leads to delamination under stress.

The Consequence of Overheating

If the temperature exceeds the specific window, the matrix degrades. You risk the local melting of the AZ31 plates or the formation of excessive reaction products.

While some reaction phases are beneficial, uncontrolled high temperatures can lead to an overabundance of brittle compounds or material leakage, compromising the composite's ductility.

Optimizing Your Sintering Protocol

To ensure the successful fabrication of AZ31/UCF/AZ31 composites, your process control must be rigorous.

- If your primary focus is Interfacial Strength: Target the precise melting point of the binder (approx. 585°C) to ensure maximum wetting and the formation of Al4C3 and MgAl2C2 phases.

- If your primary focus is Dimensional Accuracy: strictly limit temperature overshoot to prevent the AZ31 matrix plates from entering their softening range.

Success relies on maintaining the delicate balance where the binder is liquid enough to act, but the matrix remains solid enough to endure.

Summary Table:

| Factor | Effect of Precise Temperature Control (585°C) | Risk of Deviation |

|---|---|---|

| Binder State | Melts AZ91 powder for complete fiber wetting | Poor adhesion (too low) or material leakage (too high) |

| Matrix Stability | Keeps AZ31 plates solid for structural integrity | Structural deformation and softening (too high) |

| Interfacial Phase | Promotes formation of Al4C3 and MgAl2C2 | Incomplete diffusion or brittle compound overgrowth |

| Bond Quality | Ensures high-strength chemical and mechanical bonding | Delamination and high porosity (too low) |

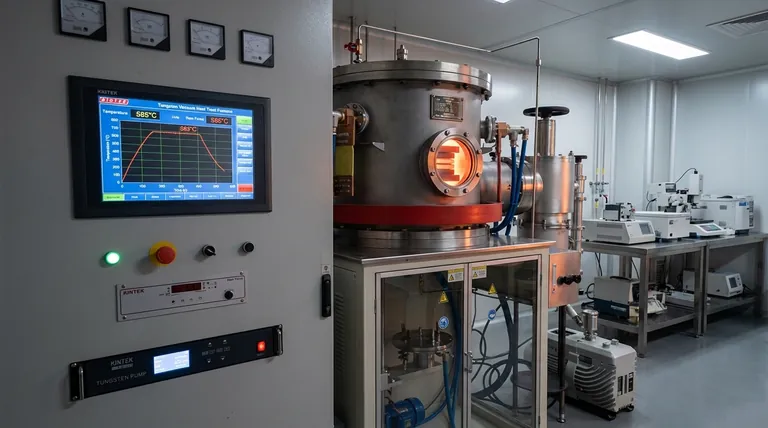

Elevate Your Composite Fabrication with KINTEK Precision

Achieving the perfect thermal window for AZ31/UCF/AZ31 composites requires uncompromising equipment accuracy. KINTEK provides industry-leading Vacuum Hot Pressing systems, alongside our specialized Muffle, Tube, Rotary, and CVD furnaces, all engineered to deliver the exact temperature uniformity your R&D demands.

Our systems are fully customizable to meet the unique challenges of advanced material sintering and interfacial bonding. Backed by expert R&D and world-class manufacturing, we help you eliminate process variables and secure superior material performance.

Ready to optimize your thermal processing? Contact KINTEK Today to Discuss Your Custom Solution

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the mold configuration requirements for sintering non-conductive powders in FAST? Expert Setup Guide

- Why is isostatic graphite the most common material for SPS molds? Unlock High-Performance Sintering Precision

- What are the advantages of industrial SPS vs traditional sintering for SiC? Superior Density and Fine-Grain Structure

- What function does a vacuum hot press furnace serve in the densification of Nb-22.5Cr-5Si alloys? Achieve Full Density and Purity for Refractory Alloys

- How does the capability for long-duration temperature control in a vacuum hot pressing furnace improve ZnS ceramics?

- What is the primary function of graphite foil within the FAST system? Optimize Your Sintering and Tooling Protection

- Why is a Vacuum Hot Press (VHP) furnace preferred over stir casting? Achieve Near-Theoretical Density for Composites

- What role do graphite molds play in the vacuum hot press sintering process of IZO targets? Ensuring Purity and Density