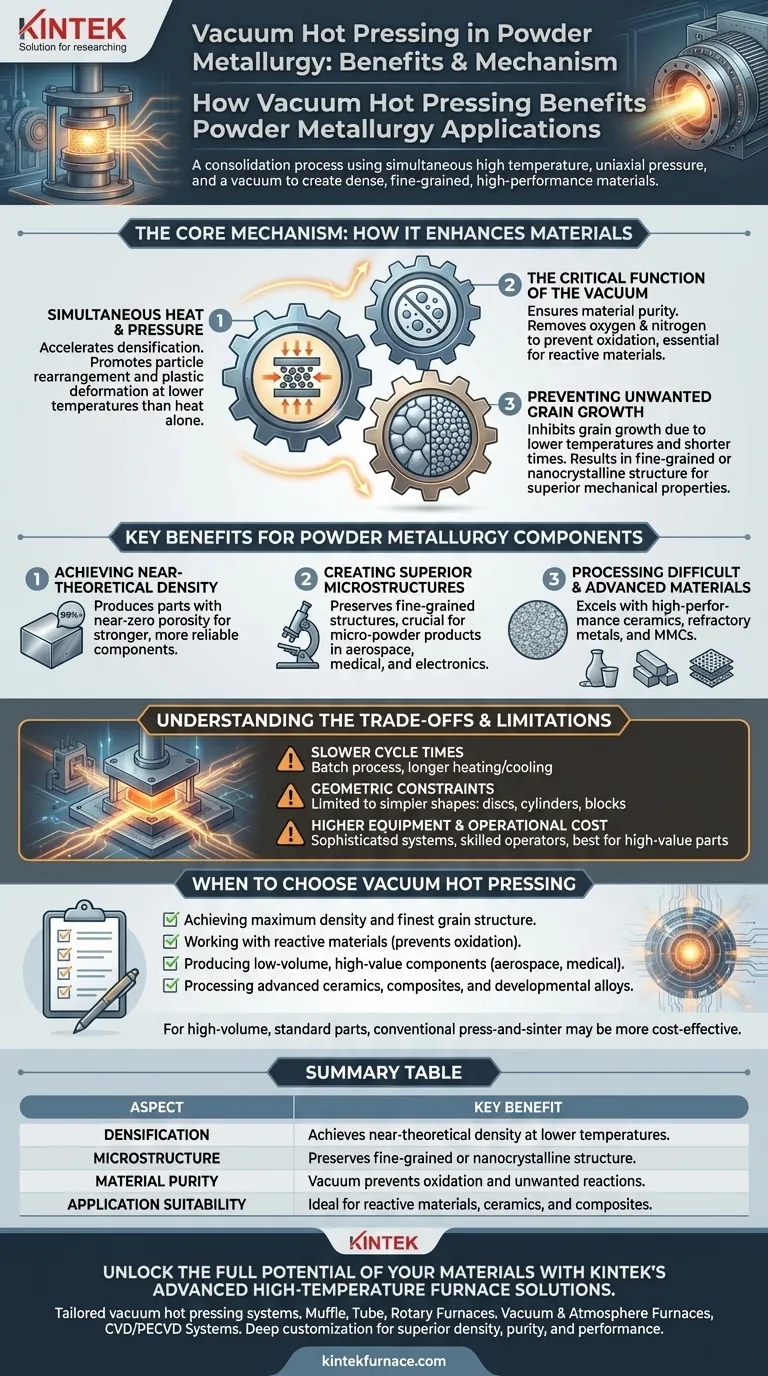

In powder metallurgy, vacuum hot pressing is a consolidation process used to create exceptionally dense, high-performance materials with a fine-grained microstructure. It achieves this by simultaneously applying high temperature and uniaxial pressure to a powder within a vacuum. This combination allows for full densification at temperatures lower than conventional sintering, which is critical for preventing the grain growth that can degrade mechanical properties.

The fundamental advantage of vacuum hot pressing lies in its ability to achieve near-full densification at lower temperatures than pressureless methods. This preserves the fine-grained microstructure essential for creating materials with superior strength, hardness, and performance, especially when working with advanced or reactive powders.

The Core Mechanism: How It Enhances Materials

Vacuum hot pressing is not just a heating process; it's a synergistic combination of three distinct elements: pressure, temperature, and a controlled atmosphere. Understanding how these work together reveals why it is so effective.

The Role of Simultaneous Heat and Pressure

Applying uniaxial pressure while the material is hot dramatically accelerates densification. The pressure promotes particle rearrangement and plastic deformation, closing the voids between powder particles much more effectively and at lower temperatures than heat alone.

The Critical Function of the Vacuum

The vacuum environment is essential for material purity. By removing atmospheric gases like oxygen and nitrogen, it prevents unwanted chemical reactions, such as oxidation. This is non-negotiable when processing reactive materials like refractory metals or certain advanced ceramics.

Preventing Unwanted Grain Growth

A material's strength is often inversely related to its grain size. Because vacuum hot pressing allows for densification at lower temperatures and for shorter times, it inhibits grain growth. This results in a final product with a fine-grained or even nanocrystalline structure, which directly translates to superior mechanical properties.

Key Benefits for Powder Metallurgy Components

The unique mechanism of vacuum hot pressing delivers tangible advantages in the final component, enabling the production of materials that are impossible to create with other methods.

Achieving Near-Theoretical Density

The primary benefit is the ability to produce parts with near-zero porosity. The applied pressure effectively squeezes out voids, resulting in a fully dense component that is stronger and more reliable under stress.

Creating Superior Microstructures

The process is unmatched for producing materials with a stable, fine-grained microstructure. This is particularly effective for micro-powder products, where preserving the initial small particle size is critical for the final properties. This control is essential for applications in aerospace, medical devices, and electronics.

Processing Difficult and Advanced Materials

Vacuum hot pressing excels at consolidating materials that are difficult to sinter using conventional methods. This includes high-performance industrial ceramics, refractory metals, and metal matrix composites (MMCs) that demand both high density and a pure, controlled microstructure.

Understanding the Trade-offs and Limitations

While powerful, vacuum hot pressing is a specialized process with specific constraints. An objective evaluation requires acknowledging its trade-offs compared to other manufacturing techniques.

Slower Cycle Times

Vacuum hot pressing is inherently a batch process. The time required for loading the die, pumping down the vacuum, heating, pressing, and cooling makes it slower than continuous methods or high-volume press-and-sinter operations.

Geometric Constraints

The use of a uniaxial die and punch generally limits the process to simpler shapes, such as discs, cylinders, and rectangular blocks. Complex, near-net-shape parts are often better suited for methods like metal injection molding (MIM) or hot isostatic pressing (HIP).

Higher Equipment and Operational Cost

Vacuum hot press systems are sophisticated and represent a significant capital investment. They require skilled operators and have higher running costs compared to conventional furnaces, making the process best suited for high-value components where performance justifies the expense.

When to Choose Vacuum Hot Pressing

Your choice of consolidation method depends entirely on the material you are using and the performance you need to achieve.

- If your primary focus is achieving maximum density and the finest possible grain structure: Vacuum hot pressing is the ideal choice, especially for advanced ceramics, composites, and developmental alloys.

- If you are working with reactive materials that cannot tolerate atmospheric exposure: The vacuum environment is non-negotiable to prevent oxidation and ensure the material's integrity.

- If your goal is producing low-volume, high-value components for critical applications: The process offers unparalleled control over microstructure, justifying the slower cycle time for aerospace or medical parts.

- If you need to produce high volumes of standard metal parts with moderate performance requirements: A more cost-effective method like conventional press-and-sinter is the appropriate choice.

Ultimately, selecting vacuum hot pressing is a strategic decision to prioritize final material properties and performance over production speed and cost.

Summary Table:

| Aspect | Key Benefit |

|---|---|

| Densification | Achieves near-theoretical density at lower temperatures |

| Microstructure | Preserves fine-grained or nanocrystalline structure |

| Material Purity | Vacuum prevents oxidation and unwanted reactions |

| Application Suitability | Ideal for reactive materials, ceramics, and composites |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored vacuum hot pressing systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior density, purity, and performance for high-value components. Contact us today to discuss how we can enhance your powder metallurgy applications!

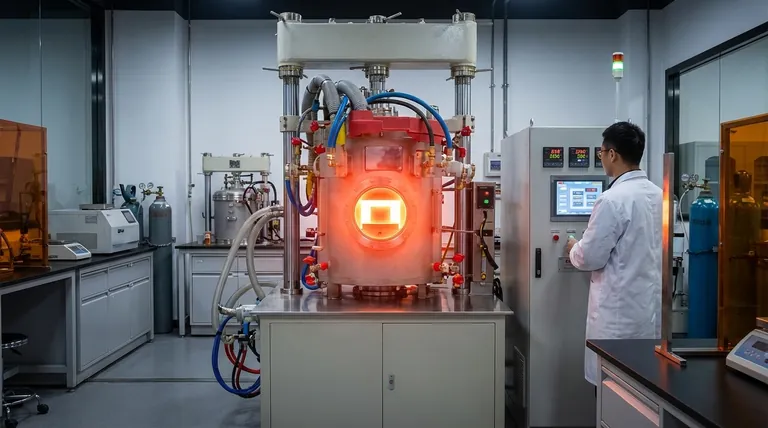

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the primary components of a vacuum hot press furnace? Master the Core Systems for Precise Material Processing

- What are the advantages of using a laboratory hot press for F-MWCNT films? Boost Power Factor by 400%

- What is a vacuum hot press furnace? Unlock Superior Material Performance

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density