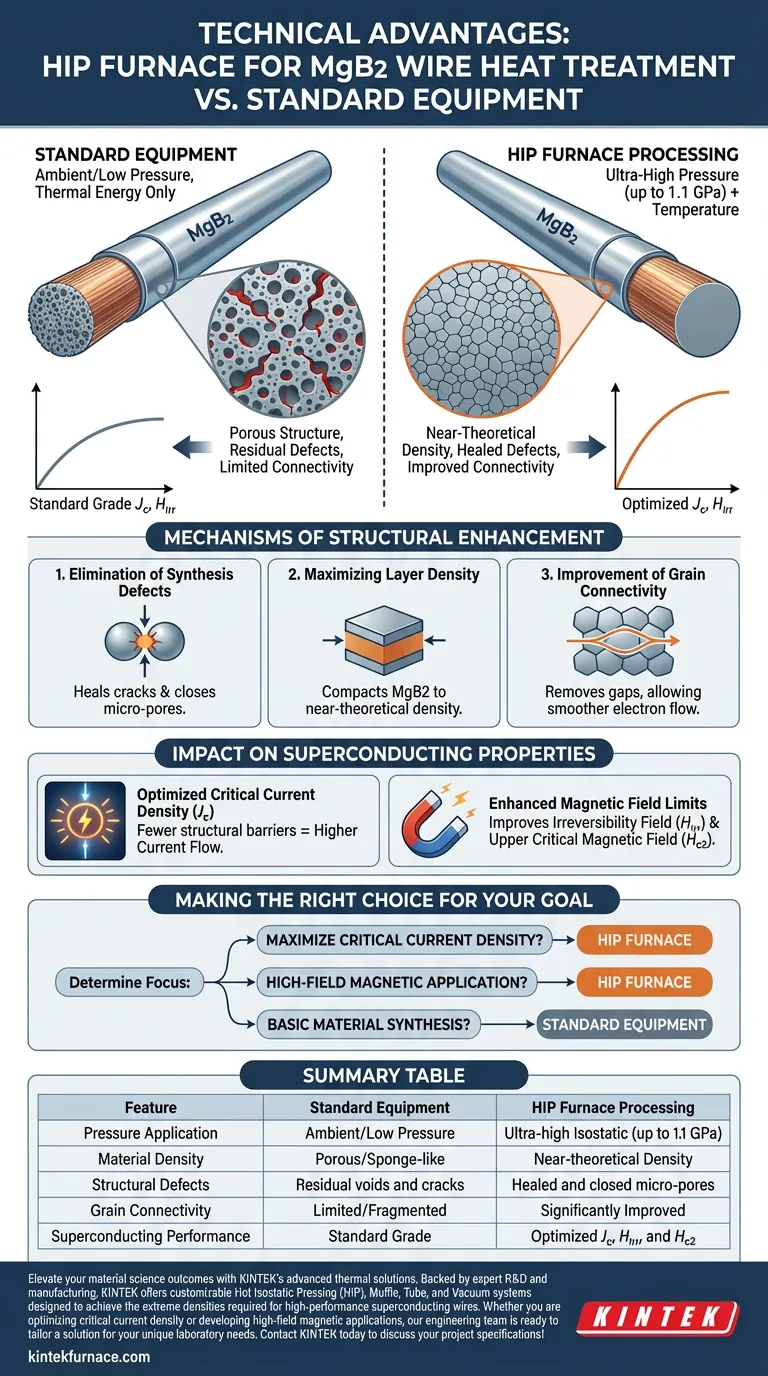

The primary technical advantage of using a Hot Isostatic Pressing (HIP) furnace for MgB2 wires is the simultaneous application of ultra-high pressure and temperature to correct structural defects. While standard equipment relies on thermal energy alone, a HIP furnace applies isostatic pressures reaching up to 1.1 GPa during the 700°C annealing stage, fundamentally altering the microstructure of the wire.

By introducing extreme pressure during heat treatment, HIP processing mechanically forces the closure of microscopic voids and cracks that standard furnaces cannot remove. This creates a denser, more connected superconducting layer, directly optimizing critical current density and magnetic field performance.

Mechanisms of Structural Enhancement

Elimination of Synthesis Defects

During the synthesis of MgB2, pores and cracks naturally form within the material. Standard heat treatment equipment lacks the mechanism to address these voids.

A HIP furnace utilizes a synergistic effect of heat and pressure to effectively eliminate these defects. The pressure forces material into voids, closing residual micro-pores and healing cracks that would otherwise interrupt current flow.

Maximizing Layer Density

The defining difference in the final product is density. Standard annealing often leaves a porous structure.

The ultra-high pressure of the HIP process (up to 1.1 GPa) compacts the MgB2 layer to near-theoretical density. This physical compaction is critical for ensuring that the superconducting material is continuous rather than fragmented.

Improvement of Grain Connectivity

High performance in superconducting wires depends on how well grains are connected.

By removing physical gaps between grains, HIP processing significantly improves grain connectivity. This reduction in granularity allows for smoother electron flow across the material boundaries.

Impact on Superconducting Properties

Optimized Critical Current Density ($J_c$)

The elimination of pores and improved connectivity has a direct impact on electrical performance.

With fewer structural barriers to impede current, the critical current density is significantly optimized compared to wires processed in standard furnaces.

Enhanced Magnetic Field Limits

The structural integrity provided by HIP processing extends the operational limits of the wire in magnetic fields.

Specifically, the treatment improves both the irreversibility field ($H_{irr}$) and the upper critical magnetic field ($H_{c2}$). This makes the wire viable for applications requiring higher magnetic performance than standard wires can sustain.

The Limitations of Standard Processing

Inability to Heal Structural Voids

It is important to recognize why standard equipment often yields lower performance. Standard furnaces operate at ambient or low pressures, relying solely on diffusion to bond materials.

Without the driving force of isostatic pressure, diffusion alone is often insufficient to close the voids created during the chemical reaction of Magnesium and Boron.

Compromised Microstructure

Wires treated without high pressure retain a "sponge-like" porosity.

This remaining porosity acts as a bottleneck for performance, limiting both the mechanical stability and the superconducting capacity of the final wire.

Making the Right Choice for Your Goal

To determine if the transition to HIP processing is necessary for your specific application, consider your performance requirements.

- If your primary focus is maximizing critical current density: You must use HIP processing to achieve the high grain connectivity and density required for peak electrical transport.

- If your primary focus is high-field magnetic application: The HIP furnace is essential to optimize the irreversibility field and upper critical magnetic field limits.

- If your primary focus is basic material synthesis: Standard equipment is sufficient for phase formation but will result in lower density and reduced performance capabilities.

The superior density achieved through ultra-high pressure is the defining factor that separates high-performance MgB2 wires from standard grade materials.

Summary Table:

| Feature | Standard Equipment | HIP Furnace Processing |

|---|---|---|

| Pressure Application | Ambient or Low Pressure | Ultra-high Isostatic (up to 1.1 GPa) |

| Material Density | Porous/Sponge-like | Near-theoretical Density |

| Structural Defects | Residual voids and cracks | Healed and closed micro-pores |

| Grain Connectivity | Limited/Fragmented | Significantly Improved |

| Superconducting Performance | Standard Grade | Optimized $J_c$, $H_{irr}$, and $H_{c2}$ |

Elevate your material science outcomes with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers customizable Hot Isostatic Pressing (HIP), Muffle, Tube, and Vacuum systems designed to achieve the extreme densities required for high-performance superconducting wires. Whether you are optimizing critical current density or developing high-field magnetic applications, our engineering team is ready to tailor a solution for your unique laboratory needs. Contact KINTEK today to discuss your project specifications!

Visual Guide

References

- Daniel Gajda, Tomasz Czujko. Investigation of Layered Structure Formation in MgB2 Wires Produced by the Internal Mg Coating Process under Low and High Isostatic Pressures. DOI: 10.3390/ma17061362

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a hot press sintering furnace play in Cf-UHTC production? Achieve Peak Density in Refractory Composites

- Why is vacuum hot press sintering recommended over pressureless sintering? Achieve Peak Density for IZO Ceramic Targets

- What is the significance of the rapid heating capability of a hot press furnace? Unlock Nanoscale Sintering Precision

- How does the vacuum environment affect AlMgTi composite hot pressing? Unlock Superior Bonding & Density

- Why is multi-stage pressure regulation required in a vacuum hot press furnace? Optimize Ti-Al3Ti Composite Sintering

- What is a vacuum press machine? Achieve Perfect, Void-Free Lamination and Densification

- What applications does Vacuum Hot Press technology have in the electronics and semiconductor industry? Unlock High-Performance Component Manufacturing

- What role does a Spark Plasma Sintering (SPS) system play in the preparation of Al0.3CoCrFeNiMo0.75 bulk materials?