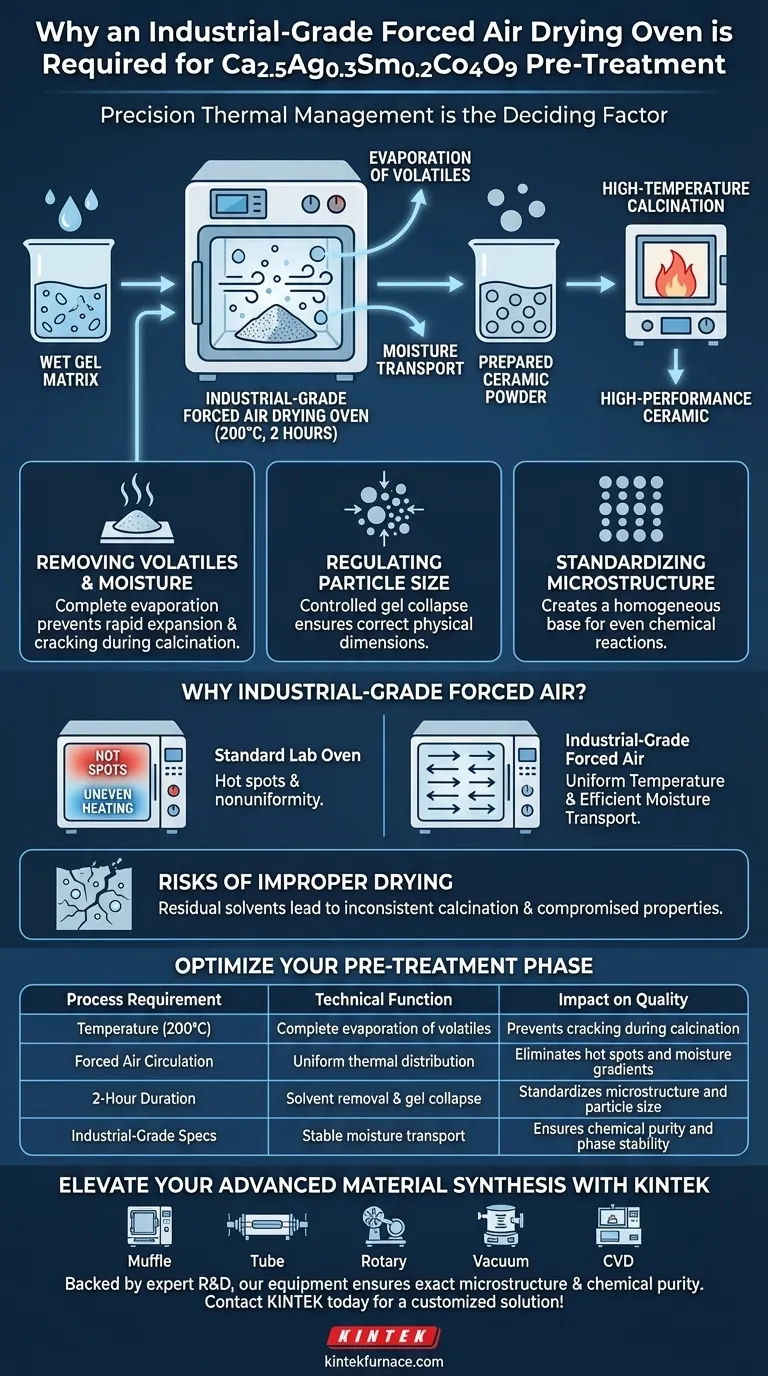

Precision thermal management is the deciding factor in the successful synthesis of complex ceramics like Ca2.5Ag0.3Sm0.2Co4O9. An industrial-grade forced air drying oven is required to maintain a strictly controlled 200 °C environment for a duration of two hours. This specific thermal treatment is necessary to fully evaporate residual water and volatile solvents from the initial gel matrix, ensuring the material is chemically and structurally prepared for high-temperature calcination.

The primary function of this drying phase is to bridge the gap between the wet gel state and the final solid ceramic. By standardizing the microstructure and regulating particle size at a moderate temperature, the process prevents structural failure during the subsequent, more aggressive calcination stage.

The Critical Functions of Thermal Pre-Treatment

Removing Volatiles and Moisture

The synthesis of Ca2.5Ag0.3Sm0.2Co4O9 often begins with a wet chemical process, resulting in a gel. This gel matrix is saturated with residual water and volatile solvents that must be removed gently.

If these volatiles remain trapped within the matrix during high-temperature calcination, they can expand rapidly, causing the material to crack or burst. The 200 °C treatment ensures a complete, controlled evaporation.

Regulating Particle Size

Drying is not merely about removing liquid; it is a morphological step. As the solvents evaporate, the gel network collapses and densifies.

By controlling this collapse in a stable oven, you actively regulate the particle size of the precursor powder. This ensures the final ceramic powder has the correct physical dimensions for its intended application.

Standardizing the Microstructure

Uniformity is essential for high-performance ceramics. The drying phase acts as a preliminary standardization step for the material's microstructure.

This creates a homogeneous base, ensuring that when the material enters the calcination phase, the chemical reactions occur evenly throughout the entire sample.

Why Industrial-Grade Forced Air is Necessary

Ensuring Temperature Uniformity

Standard laboratory ovens often suffer from "hot spots" or uneven heating. An industrial-grade forced air system uses convection to circulate air continuously.

This guarantees that every part of the sample—regardless of its position in the oven—is exposed to the exact same 200 °C temperature, preventing uneven drying rates.

Facilitating Moisture Transport

Static air quickly becomes saturated with moisture, slowing down evaporation. Forced air systems constantly replace the saturated air around the sample with fresh, dry, heated air.

This mechanism is critical for the "moisture removal" function mentioned in your reference, ensuring the drying process completes efficiently within the two-hour window.

Risks of Improper Drying

The Danger of Residual Solvents

If the drying environment fluctuates or the airflow is insufficient, pockets of solvent may remain deep within the gel.

This leads to inconsistent calcination results, where the internal structure of the ceramic differs from the surface, ultimately compromising the material's thermoelectric or structural properties.

Microstructural Inconsistency

Failing to standardize the microstructure at this stage creates a "garbage in, garbage out" scenario for the calcination furnace.

Inconsistencies formed during drying are often permanent. They can lead to weak points, agglomeration, or phase separation in the final Ca2.5Ag0.3Sm0.2Co4O9 powder.

Optimizing the Pre-Treatment Phase

To ensure the highest quality ceramic powder, you must align your drying parameters with your synthesis goals.

- If your primary focus is Structural Integrity: Ensure the forced air circulation is maximized to prevent any moisture gradients that could lead to cracking.

- If your primary focus is Chemical Purity: Adhere strictly to the full 2-hour duration to guarantee that absolutely no organic solvents remain to contaminate the calcination phase.

A stable, uniform drying phase is the foundation upon which high-performance ceramic properties are built.

Summary Table:

| Process Requirement | Technical Function | Impact on Quality |

|---|---|---|

| Temperature (200°C) | Complete evaporation of volatiles | Prevents cracking during calcination |

| Forced Air Circulation | Uniform thermal distribution | Eliminates hot spots and moisture gradients |

| 2-Hour Duration | Solvent removal & gel collapse | Standardizes microstructure and particle size |

| Industrial-Grade Specs | Stable moisture transport | Ensures chemical purity and phase stability |

Elevate Your Advanced Material Synthesis with KINTEK

Precision in the drying phase is the foundation of high-performance ceramics. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable industrial-grade drying ovens designed for strict thermal management.

Backed by expert R&D and manufacturing, our equipment ensures your Ca2.5Ag0.3Sm0.2Co4O9 powders achieve the exact microstructure and chemical purity required for superior thermoelectric performance.

Ready to optimize your lab's heating process?

Contact KINTEK today for a customized solution!

Visual Guide

References

- Enes Kılınç, Erdal Çelik. Sol–Gel Synthesis of Ca<sub>2.5</sub>Ag<sub>0.3</sub>Sm<sub>0.2</sub>Co<sub>4</sub>O<sub>9</sub> Semiconducting Materials for Thermoelectric Applications in Aerospace Systems. DOI: 10.1002/adem.202500571

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is high-purity argon gas used to purge the furnace? Ensure Precision in TGA Oxidation Kinetic Tests

- What physical environment does a laboratory oven provide for perovskite annealing? Master Thermal Precision & Strain Control

- Why do substrates undergo treatment in a high-temperature annealing furnace? Perfecting PtTe2/WTe2 Heterostructures

- What is the purpose of performing a 1200°C solution treatment for high-entropy alloys? Achieve Total Homogenization

- Why must a laboratory drying furnace undergo a preheating stage? Ensure Accurate Mango Seed Drying Data

- What are the requirements for sulfur powder loading in MoS2 synthesis? Master the 50-150 mg Precision Range

- What are the process advantages of using an electric melting furnace with an adjustable thermostat? Optimize Copper Scrap Refining

- What is the function of a magnetron sputtering system for WS2 thin films? Master Nano-Scale Deposition Control