Precision drying is the critical bridge between cleaning raw biomass and chemically activating it. For cherry pits specifically, using a precision oven at 120°C for 24 hours is required to completely remove free moisture from the pores, ensuring the material is chemically and physically ready for impregnation.

The precision oven eliminates moisture that would otherwise dilute the activating agent. By clearing the porous structure, it ensures the phosphoric acid ($H_3PO_4$) can penetrate deeply and react at the intended concentration ratio.

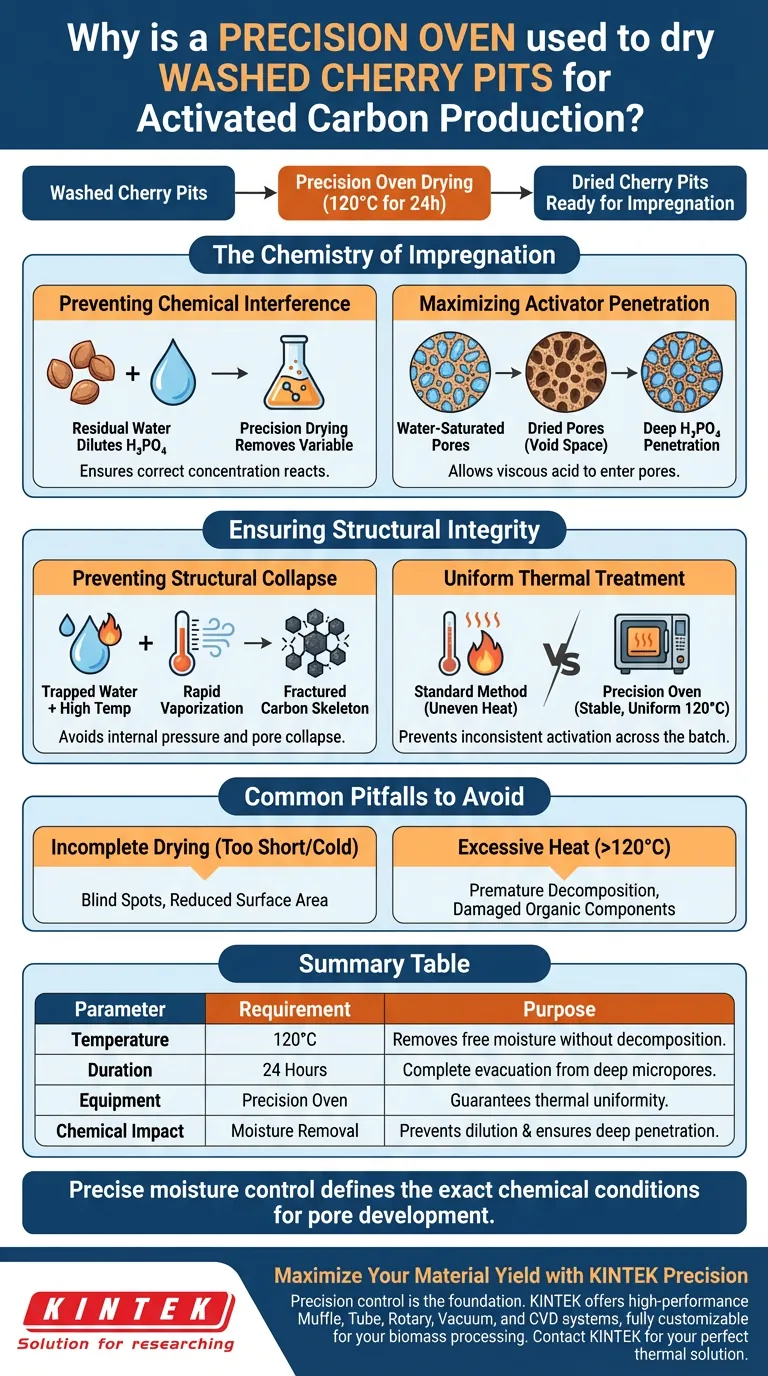

The Chemistry of Impregnation

Preventing Chemical Interference

The production of activated carbon relies on a precise ratio between the biomass and the chemical activator (specifically $H_3PO_4$ in this context).

Residual water in the cherry pits acts as an uncontrolled variable. It dilutes the impregnation solution, altering the concentration that actually reaches the carbon matrix.

Precision drying removes this variable, guaranteeing that the concentration you prepare is the concentration that reacts.

Maximizing Activator Penetration

Cherry pits possess a complex lignocellulosic structure. Before activation, the pores within this structure are often saturated with water from the washing process.

The drying process physically evacuates this moisture.

This evacuation creates necessary void space, allowing the viscous phosphoric acid to enter the pores and interact with the internal surface area of the biomass.

Ensuring Structural Integrity

Preventing Structural Collapse

While the primary focus is preparing for impregnation, thorough drying also protects the material during later stages.

If significant moisture remains, subsequent high-temperature processing can cause rapid vaporization of trapped water.

This internal pressure can fracture the carbon skeleton, leading to a collapse of the pore structure you are trying to create.

Uniform Thermal Treatment

A "precision" oven is used rather than a standard drying method because it maintains a stable thermal environment.

It ensures that the entire batch of cherry pits reaches the target temperature of 120°C uniformly without local overheating.

This uniformity prevents uneven drying, which would otherwise lead to inconsistent activation results across the batch.

Common Pitfalls to Avoid

The Risk of Incomplete Drying

Reducing the drying time or temperature (below 120°C or 24 hours) often leaves bound water deep within the micropores.

This results in "blind spots" where the activator cannot reach, significantly reducing the final surface area of the activated carbon.

The Danger of Excessive Heat

Conversely, utilizing temperatures significantly higher than 120°C during this preliminary phase can induce premature decomposition.

You risk damaging the organic components of the lignocellulose before the stabilizing chemical agent ($H_3PO_4$) is introduced.

Making the Right Choice for Your Goal

To maximize the quality of your activated carbon, apply these principles to your drying protocol:

- If your primary focus is Surface Area: Ensure the drying duration is sufficient (24 hours) to clear deep micropores for maximum acid penetration.

- If your primary focus is Process Consistency: Use a certified precision oven to eliminate temperature gradients that cause batch-to-batch variation.

Precise moisture control is not just about drying; it is about defining the exact chemical conditions for pore development.

Summary Table:

| Drying Parameter | Requirement | Purpose in Activated Carbon Production |

|---|---|---|

| Temperature | 120°C | Removes free moisture without premature biomass decomposition. |

| Duration | 24 Hours | Ensures complete evacuation of moisture from deep micropores. |

| Equipment | Precision Oven | Guarantees thermal uniformity to prevent inconsistent activation. |

| Chemical Impact | Moisture Removal | Prevents dilution of $H_3PO_4$ and ensures deep activator penetration. |

Maximize Your Material Yield with KINTEK Precision

Precise moisture control is the foundation of high-performance activated carbon. At KINTEK, we understand that even minor temperature fluctuations can compromise your porous structure. Backed by expert R&D and manufacturing, we provide high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific biomass processing requirements.

Whether you are scaling up production or refining lab-scale research, our lab high-temp furnaces ensure the thermal uniformity and reliability you need to succeed. Contact KINTEK today to find the perfect thermal solution for your unique needs.

Visual Guide

References

- José M. González‐Domínguez, V. Gómez-Serrano. Surface Chemistry of Cherry Stone-Derived Activated Carbon Prepared by H3PO4 Activation. DOI: 10.3390/pr12010149

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the technical necessity of heating and stirring for K-Na alloy anodes? Ensure Peak Battery Performance

- How do the process parameters of stir casting equipment influence the wear resistance of aluminum matrix composites?

- In gas-phase aluminizing, how do high-temperature furnaces facilitate the formation of the β-NiAl phase?

- What is the mechanism of high-power microwave systems in uranium roasting? Unlock Efficiency with Volumetric Heating

- What role do high-temp furnaces play in co-firing SOFCs? Master Ceramic Densification and Sintering

- How does a high-power microwave reactor facilitate the thermal treatment of zinc clinker? Rapid Phase Transformation

- Why is precise heating rate control necessary? Master Activated Carbon Heat Treatment with KINTEK

- How does the temperature of the annealing process specifically influence the luminescence properties of ZnSe? Guide