High-temperature furnaces serve as the critical catalyst for creating the $\beta$-NiAl phase by maintaining a precise and consistent environment at 1050°C. This specific thermal profile enables the necessary chemical reaction between gaseous aluminum halides and the nickel-based substrate, driving the aluminum diffusion required to form the correct crystal structure.

The success of gas-phase aluminizing relies fundamentally on thermal stability. A consistent 1050°C environment is not just a catalyst but a structural requirement to drive the diffusion that ensures high-temperature oxidation resistance.

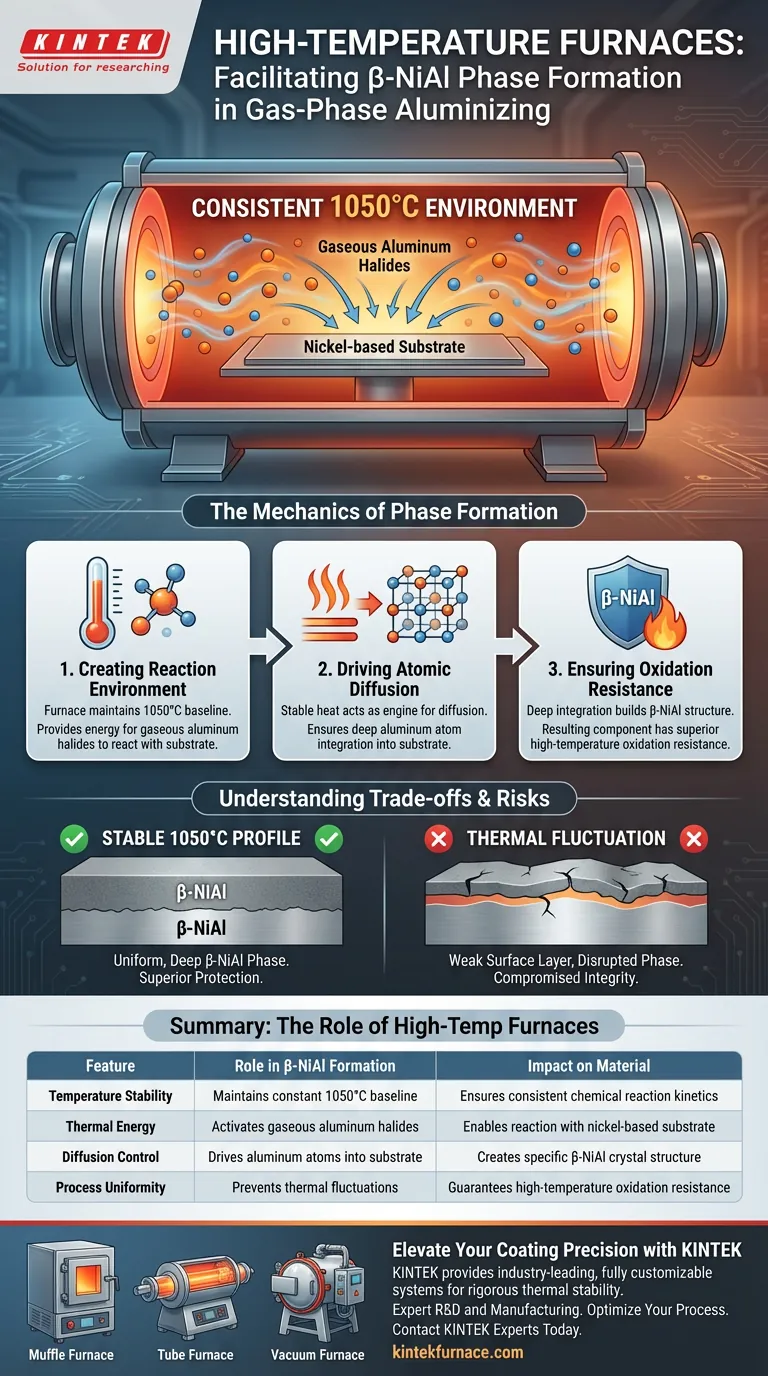

The Mechanics of Phase Formation

Creating the Reaction Environment

The primary function of the furnace is to establish a consistent 1050°C baseline.

This temperature is non-negotiable for the process. It provides the energy required for gaseous aluminum halides to chemically react effectively with the nickel-based substrate.

Driving Atomic Diffusion

Heat acts as the engine for diffusion in this process.

The furnace’s stable heat profile ensures that aluminum atoms do not just sit on the surface but diffuse correctly into the substrate. This deep atomic integration is what builds the specific $\beta$-NiAl crystal structure.

Ensuring Oxidation Resistance

The ultimate goal of this thermal process is material longevity.

By strictly maintaining the crystal structure through controlled heat, the furnace ensures the resulting component has superior high-temperature oxidation resistance.

Understanding the Trade-offs

The Risk of Thermal Fluctuation

If the furnace fails to maintain a stable 1050°C profile, the integrity of the coating is compromised.

Temperature dips can prevent the aluminum from diffusing deep enough, resulting in a weak surface layer. Conversely, excessive fluctuations may disrupt the formation of the uniform $\beta$-NiAl phase, reducing the component's lifespan.

Making the Right Choice for Your Process

To ensure the highest quality aluminizing results, focus on the thermal capabilities of your equipment.

- If your primary focus is coating integrity: Ensure your furnace can maintain a strictly stable heat profile to guarantee correct atomic diffusion.

- If your primary focus is reaction efficiency: Verify the system can sustain the 1050°C baseline required to activate the gaseous aluminum halides.

Precision in thermal management is the defining factor between a standard coating and superior surface protection.

Summary Table:

| Feature | Role in β-NiAl Formation | Impact on Material |

|---|---|---|

| Temperature Stability | Maintains a constant 1050°C baseline | Ensures consistent chemical reaction kinetics |

| Thermal Energy | Activates gaseous aluminum halides | Enables reaction with nickel-based substrate |

| Diffusion Control | Drives aluminum atoms into the substrate | Creates the specific $\beta$-NiAl crystal structure |

| Process Uniformity | Prevents thermal fluctuations | Guarantees high-temperature oxidation resistance |

Elevate Your Coating Precision with KINTEK

Don't let thermal fluctuations compromise your coating integrity. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnace systems specifically engineered to maintain the rigorous thermal stability required for gas-phase aluminizing.

Backed by expert R&D and manufacturing, our high-temperature solutions are fully customizable to meet your unique diffusion and CVD needs. Ensure superior oxidation resistance for your components with equipment designed for precision.

Contact KINTEK Experts Today to Optimize Your Process

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis