High-power microwave systems operate by inducing direct, volumetric heating within the material structure. By utilizing high-frequency electromagnetic fields, the system excites polar molecules inside the uranium tailings, causing high-speed movement and friction. This generates intense heat internally, distinct from the external layer-by-layer heating found in traditional methods.

The defining mechanism of this technology is the generation of intense thermal stress through rapid, internal heating. This stress physically fractures mineral barriers, creating micro-cracks that significantly enhance uranium accessibility during subsequent processing.

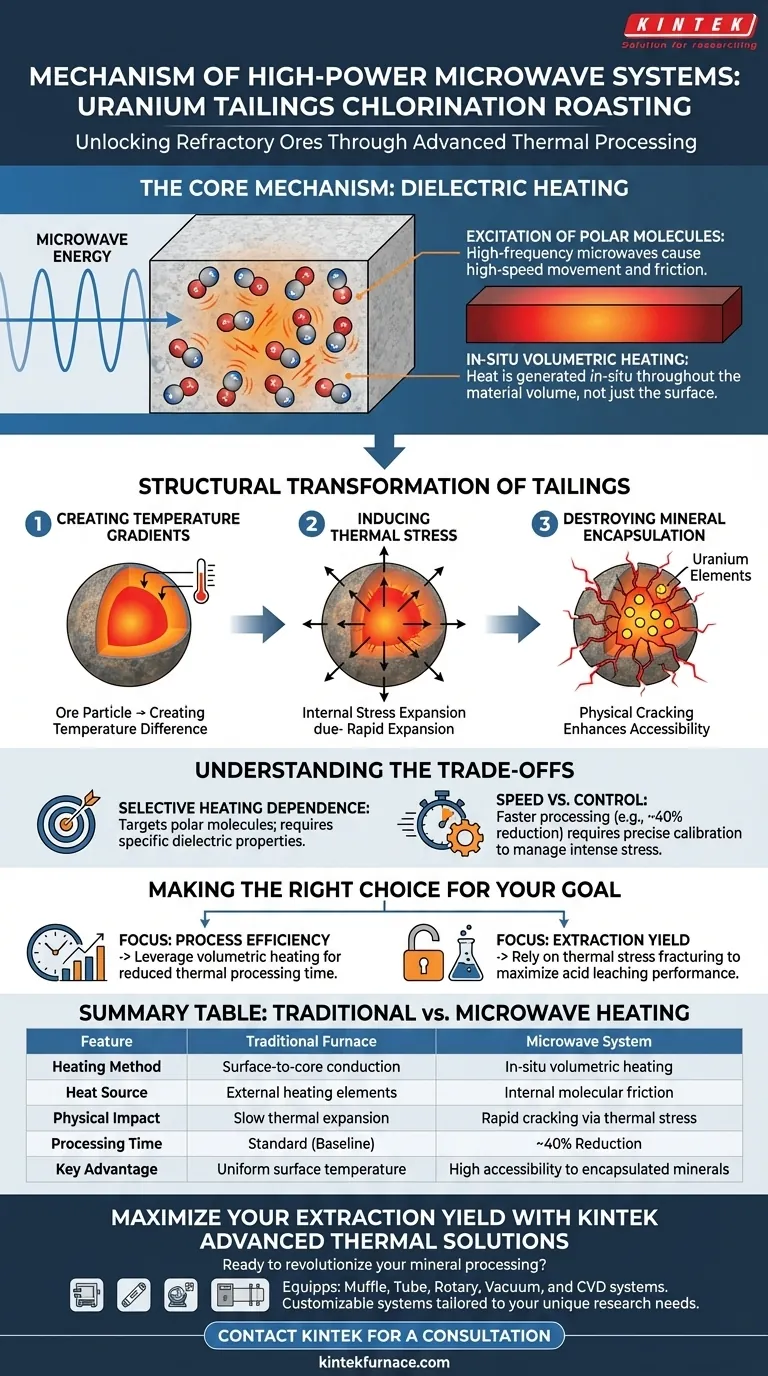

The Core Mechanism: Dielectric Heating

Excitation of Polar Molecules

The fundamental driver of this process is the interaction between the electromagnetic field and polar molecules within the uranium tailings.

When exposed to high-frequency microwaves, these molecules are forced into high-speed movement. The resulting friction between molecules converts electromagnetic energy directly into thermal energy.

In-Situ Volumetric Heating

Unlike traditional tube furnaces that rely on conduction to transfer heat from the surface to the center, microwave systems utilize volumetric heating.

This means the heat is generated in-situ (in place) throughout the volume of the material. Consequently, the internal temperature of the tailings often exceeds the surface temperature.

Structural Transformation of Tailings

Creating Temperature Gradients

The rapid, internal nature of microwave heating creates significant temperature gradients within the ore particles.

Because the heat is generated faster than it can be conducted away or equalized, distinct temperature differences develop between the inner core and the outer surface of the material.

Inducing Thermal Stress

These extreme temperature gradients lead to the development of thermal stress within the mineral structure.

As different parts of the material expand at different rates due to the heat, the internal pressure overcomes the tensile strength of the rock.

Destroying Mineral Encapsulation

The release of this thermal stress results in physical cracking of the uranium tailings.

This fracturing breaks down the physical mineral barriers (encapsulation structures) that typically trap uranium. These newly formed micro-cracks serve as pathways, exposing the uranium elements and making them accessible for subsequent acid leaching.

Understanding the Trade-offs

Selective Heating Dependence

Microwave heating is highly selective, targeting only microwave-absorbing phases and polar molecules.

While this ensures energy is directed where it is needed most, it requires the material to have specific dielectric properties. Non-polar materials may not heat as efficiently or uniformly without the presence of absorbing phases.

Speed vs. Control

The primary advantage over traditional methods is speed, reducing heating times significantly (e.g., from 20 minutes to 12 minutes).

However, this rapid rise in temperature requires precise control to manage the intense thermal stress. Without proper calibration, the aggressive cracking mechanism could potentially alter material properties beyond the intended scope.

Making the Right Choice for Your Goal

To effectively utilize high-power microwave systems in uranium roasting, consider your specific processing objectives:

- If your primary focus is process efficiency: Leverage the volumetric heating capability to reduce thermal processing time by approximately 40% compared to conventional conduction heating.

- If your primary focus is extraction yield: Rely on the thermal stress mechanism to physically fracture mineral encapsulation, creating porous pathways that maximize acid leaching performance.

Microwave roasting transforms the material physically to unlock it chemically, offering a distinct advantage in processing refractory uranium ores.

Summary Table:

| Feature | Traditional Furnace Heating | Microwave System Heating |

|---|---|---|

| Heating Method | Surface-to-core conduction | In-situ volumetric heating |

| Heat Source | External heating elements | Internal molecular friction |

| Physical Impact | Slow thermal expansion | Rapid cracking via thermal stress |

| Processing Time | Standard (Baseline) | ~40% Reduction |

| Key Advantage | Uniform surface temperature | High accessibility to encapsulated minerals |

Maximize Your Extraction Yield with KINTEK Advanced Thermal Solutions

Ready to revolutionize your mineral processing? KINTEK provides industry-leading high-temperature lab equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all precision-engineered to meet the rigorous demands of material science.

Whether you are processing refractory uranium ores or developing new material treatments, our expert R&D and manufacturing team can deliver customizable systems tailored to your unique research needs. Enhance your lab's efficiency and unlock superior extraction results today.

Contact KINTEK for a Consultation

Visual Guide

References

- Jinming Hu, Fangdong Zou. Low-Temperature Chlorination-Roasting–Acid-Leaching Uranium Process of Uranium Tailings: Comparison Between Microwave Roasting and Conventional Roasting. DOI: 10.3390/pr13010082

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are some common types of batch furnaces? Find Your Perfect Heat Treatment Solution

- Why is a laboratory vacuum oven utilized for ZnO-FL drying? Preserving Delicate Nanoparticle Morphologies

- How should materials with high moisture content be handled before heating? Ensure Safety and Quality in Thermal Processing

- How do industrial heating furnaces and rolling mills optimize Invar 36? Master Thermal Stability and Deformation

- How do the rotational and orbital movements of the sample stage contribute to the uniformity of coatings on Zircaloy?

- What is the function of a vacuum drying oven in CMS synthesis? Ensure High-Purity Precursor Integrity

- Why is rapid water quenching necessary for Ce2(Fe, Co)17 alloys? Unlock Peak Magnetocaloric Performance

- How does the QIO algorithm improve temperature control precision in electric furnaces? Achieve Global Optimization