Crucially, any material with high moisture content must be thoroughly dried before it is placed in a furnace for heating. This preliminary step is not optional; it is a critical safety and quality control measure. Failing to remove moisture, including chemically bound crystal water, before high-temperature processing can lead to catastrophic failure of both the material and the equipment.

The core principle is managing the rapid phase transition of water into steam. Skipping a dedicated pre-drying step introduces uncontrolled, high-pressure forces that can fracture the material, damage the furnace, and invalidate the entire heating process.

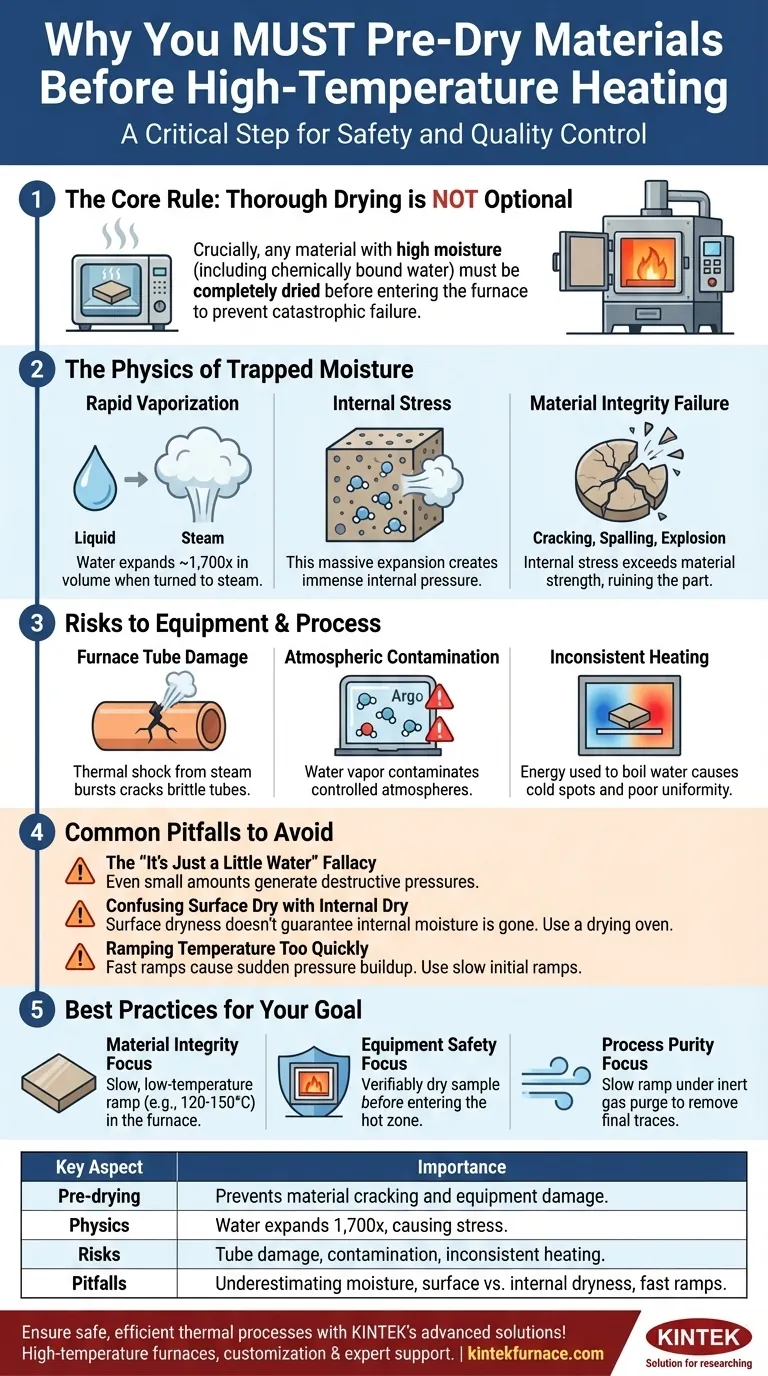

The Physics of Trapped Moisture

To understand the importance of pre-drying, you must first understand the physics at play when water is heated in a confined space. The consequences are direct and predictable.

The Problem of Rapid Vaporization

When liquid water turns into steam at atmospheric pressure, it undergoes a massive volumetric expansion of approximately 1,700 times. If this conversion happens within the microscopic pores or crystal lattice of a solid material, there is no room to accommodate this sudden change in volume.

How Steam Creates Internal Stress

This rapid expansion of trapped water generates immense internal pressure within the material. It acts like a series of tiny, localized explosions, pushing outwards against the surrounding structure. This phenomenon is what is meant by "stress" in this context.

The Impact on Material Integrity

The internal stress created by vaporizing water will almost always exceed the material's structural strength. This results in cracking, spalling (flaking of the surface), or even explosive fracturing of the entire piece. The part is ruined before the intended thermal process (like sintering or annealing) can even begin.

Risks to Equipment and Process

The danger is not limited to the material being heated. Introducing moisture into a high-temperature furnace poses significant risks to your equipment and the integrity of your process.

Furnace Tube Damage

Many high-temperature processes use ceramic (e.g., alumina) or quartz furnace tubes. These materials, while strong at high temperatures, are brittle and highly susceptible to thermal shock. A sudden burst of steam from a wet sample creates an immediate, localized cold spot on the hot tube wall, causing it to crack.

Atmospheric Contamination

Advanced processes like sintering often require a tightly controlled atmosphere (such as argon or a vacuum) to prevent unwanted chemical reactions. Releasing a large volume of water vapor completely contaminates this atmosphere, rendering the process results unreliable or useless.

Inconsistent Heating

Energy is required to turn water into steam—a concept known as the latent heat of vaporization. A wet sample will force the furnace to expend a significant amount of energy on boiling water rather than on heating the material itself. This creates cold spots and prevents the uniform, predictable heating required for quality results.

Common Pitfalls to Avoid

Simply knowing the rule is not enough. Understanding the common ways operators make mistakes is key to developing a reliable process.

The "It's Just a Little Water" Fallacy

Even a small, seemingly insignificant amount of moisture can cause damage. Given the massive expansion ratio of water to steam, it takes very little liquid to generate destructive pressures inside a porous material.

Confusing Surface Dry with Internal Dry

A material can feel perfectly dry to the touch while still retaining significant moisture within its internal pore structure. This is especially true for pressed powders, green ceramic bodies, and hygroscopic (water-absorbing) materials. A proper drying cycle in a low-temperature oven is the only way to ensure the material is truly dry.

Ramping Temperature Too Quickly

Even if a material seems dry, a slow initial temperature ramp inside the primary furnace (e.g., 1-5°C per minute up to 200°C) is a wise precaution. This allows any residual moisture or crystal water to be driven off gently, preventing the sudden pressure buildup that a fast ramp would cause.

Making the Right Choice for Your Goal

Your pre-heating protocol should be designed around your most critical objective. Use a low-temperature drying oven for the primary drying step, then consider these goals for the furnace process itself.

- If your primary focus is material integrity: Use a slow, low-temperature ramp (e.g., holding at 120-150°C) as the first step in your furnace profile to gently drive off any remaining moisture before proceeding to higher temperatures.

- If your primary focus is equipment safety: Ensure the sample is verifiably dry before it enters the hot zone of the furnace to prevent any possibility of thermal shock to the furnace tube.

- If your primary focus is process purity: After an initial drying step, slowly ramp the furnace under a light purge of inert gas to carry away any final traces of water vapor before pulling a vacuum or beginning the reactive phase of your process.

Proper moisture management is not an optional step; it is fundamental to achieving safe, repeatable, and successful thermal processing.

Summary Table:

| Key Aspect | Importance |

|---|---|

| Pre-drying | Removes moisture to prevent material cracking and equipment damage |

| Physics | Water expands 1,700x as steam, causing internal stress and failure |

| Risks | Includes furnace tube damage, atmospheric contamination, and inconsistent heating |

| Common Pitfalls | Avoid underestimating moisture, confusing surface vs. internal dryness, and fast temperature ramps |

| Goals | Tailor protocols for material integrity, equipment safety, or process purity |

Ensure your thermal processes are safe and efficient with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your lab's performance and reliability!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation