The most common types of batch furnaces are the box, pit, car-bottom, and bell furnace. Each of these designs is purpose-built to solve specific material handling and processing challenges, from treating small, general-purpose parts to processing massive industrial components. The right choice is determined by the size, shape, and weight of your parts, as well as the specific heat treatment cycle required.

The core decision in selecting a batch furnace is not about finding the "best" furnace, but about precisely matching the furnace's architecture to your operational reality—the geometry of your parts, the method of loading, and the level of atmospheric control your process demands.

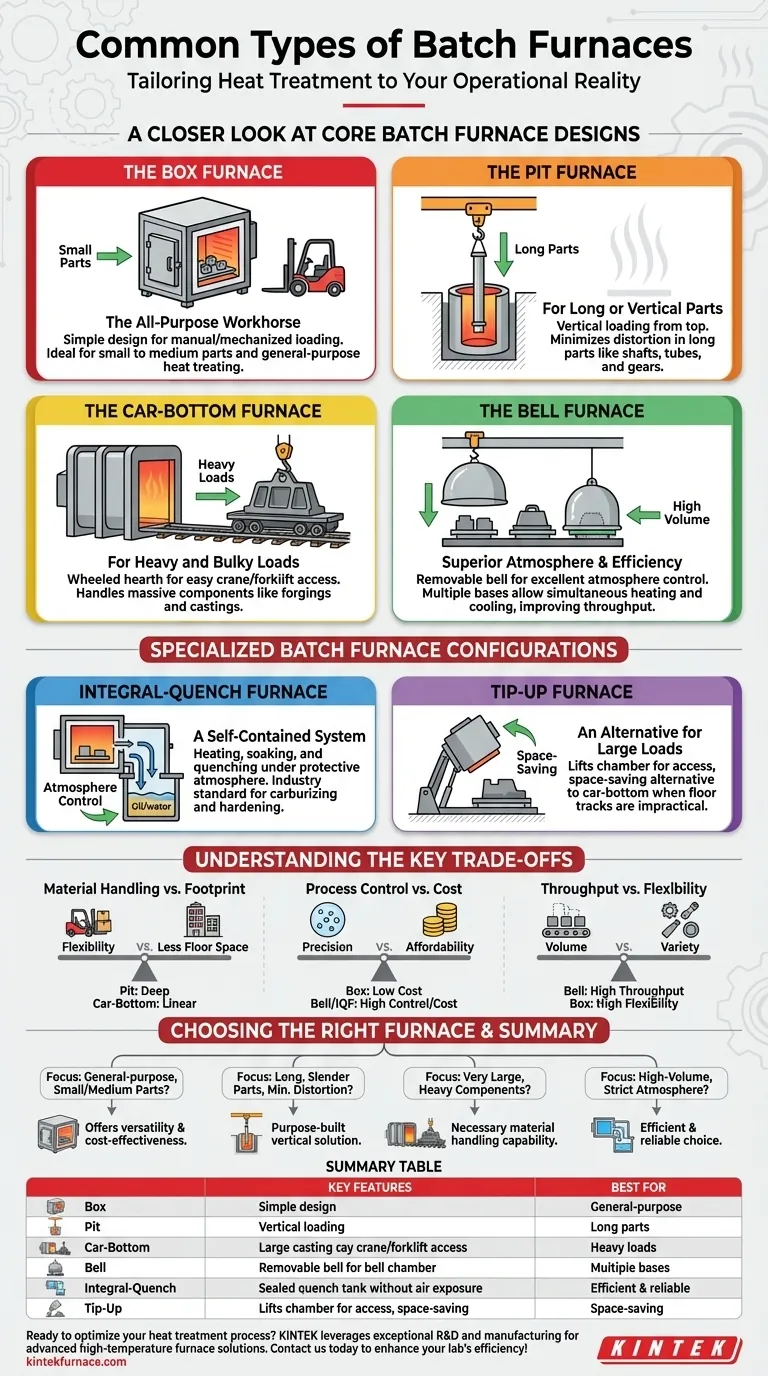

A Closer Look at Core Batch Furnace Designs

A batch furnace processes a single load, or "batch," of material at a time. The fundamental difference between types lies in how they are configured and how that batch is loaded, heated, and unloaded.

The Box Furnace: The All-Purpose Workhorse

The box furnace is the most straightforward design, essentially an insulated chamber with a door on one side for loading and unloading. Its simplicity makes it incredibly versatile.

These furnaces are ideal for a wide variety of heat-treating applications involving small to medium-sized parts that can be manually loaded or placed on a tray with a forklift. Specialized versions, known as mechanized box furnaces, can include integrated loaders and quench tanks.

The Pit Furnace: For Long or Vertical Parts

A pit furnace is a cylindrical furnace installed in a pit, placing its opening at floor level. Parts are loaded vertically from the top, typically using an overhead crane.

This vertical orientation is its key advantage. It is the ideal solution for long, slender parts like shafts, tubes, and gears, as it allows them to be suspended or fixtured vertically to minimize sagging and distortion during heating.

The Car-Bottom Furnace: For Heavy and Bulky Loads

The car-bottom furnace, also known as a car furnace, is designed to handle extremely large and heavy loads. The furnace floor, or hearth, is built onto a wheeled "car" that moves on rails.

To load it, the car is rolled out from the main furnace body, providing unobstructed access for overhead cranes or large forklifts. It is the standard for treating massive components like large forgings, castings, and complex fabrications that are too heavy or cumbersome for other designs.

The Bell Furnace: Superior Atmosphere and Efficiency

A bell furnace features a stationary, load-bearing base and a removable heating chamber, or "bell," that is lowered over the load.

This design offers two primary benefits. First, it provides an excellent seal, making it superior for processes that require tightly controlled atmospheres over long cycles. Second, a single bell can service multiple bases, allowing one load to cool under atmosphere while another is being heated, significantly improving operational efficiency.

Specialized Batch Furnace Configurations

Beyond the core types, several specialized designs address more specific process needs.

The Integral-Quench Furnace: A Self-Contained System

The integral-quench furnace is a highly efficient, self-contained unit. It is essentially a box furnace with a sealed vestibule and an integrated quench tank filled with oil, water, or salt.

The entire process—heating, soaking, and quenching—occurs under a protective atmosphere without exposing the hot parts to air. This makes it the industry standard for processes like carburizing, carbonitriding, and neutral hardening where surface chemistry and brightness are critical.

The Tip-Up Furnace: An Alternative for Large Loads

Similar in application to a car-bottom furnace, a tip-up furnace lifts its entire heating chamber up and away from a stationary hearth. This provides excellent access for loading heavy parts and can be a space-saving alternative where floor tracks for a car are not practical.

Understanding the Key Trade-offs

Choosing a furnace involves balancing competing factors. What you gain in one area, you often trade for another.

Material Handling vs. Footprint

A pit furnace saves valuable floor space but requires a deep foundation and sufficient overhead clearance for a crane. A car-bottom furnace, conversely, requires a significant amount of linear floor space to accommodate the car and its tracks.

Process Control vs. Cost

A simple box furnace is cost-effective and flexible for general-purpose work. However, achieving the high-purity atmosphere control of a bell furnace or the seamless process flow of an integral-quench furnace requires a more complex and expensive system.

Throughput vs. Flexibility

A bell furnace with multiple bases can dramatically increase throughput for long, repeatable cycles. A standard box furnace, however, offers greater flexibility for a job shop that handles a wide variety of parts with different process requirements each day.

Choosing the Right Furnace for Your Process

Your final decision should be guided by a clear understanding of your primary operational goal.

- If your primary focus is general-purpose heat treating of various small to medium parts: A box furnace offers the most versatility and cost-effectiveness.

- If your primary focus is processing long, slender parts like shafts to minimize distortion: A pit furnace is the purpose-built solution.

- If your primary focus is treating very large, heavy, or bulky components: A car-bottom furnace provides the necessary material handling capability.

- If your primary focus is high-volume processing with strict atmosphere control, like carburizing: An integral-quench furnace is the most efficient and reliable choice.

By matching the furnace's design to your specific part geometry, handling needs, and process requirements, you ensure an efficient and effective heat treatment operation.

Summary Table:

| Type | Key Features | Best For |

|---|---|---|

| Box Furnace | Simple design, versatile, manual or mechanized loading | Small to medium parts, general-purpose heat treating |

| Pit Furnace | Vertical loading, installed in pit, minimizes distortion | Long or slender parts like shafts and tubes |

| Car-Bottom Furnace | Wheeled hearth for heavy loads, crane accessible | Large, heavy components such as forgings and castings |

| Bell Furnace | Removable bell, excellent atmosphere control, efficient with multiple bases | High-volume processes requiring strict atmosphere control |

| Integral-Quench Furnace | Integrated quench tank, self-contained, protective atmosphere | Carburizing, carbonitriding, neutral hardening |

| Tip-Up Furnace | Lifts chamber for access, space-saving alternative | Heavy loads where car-bottom tracks are impractical |

Ready to optimize your heat treatment process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're handling small parts or massive industrial components, we can help you achieve superior results. Contact us today to discuss how our batch furnaces can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis