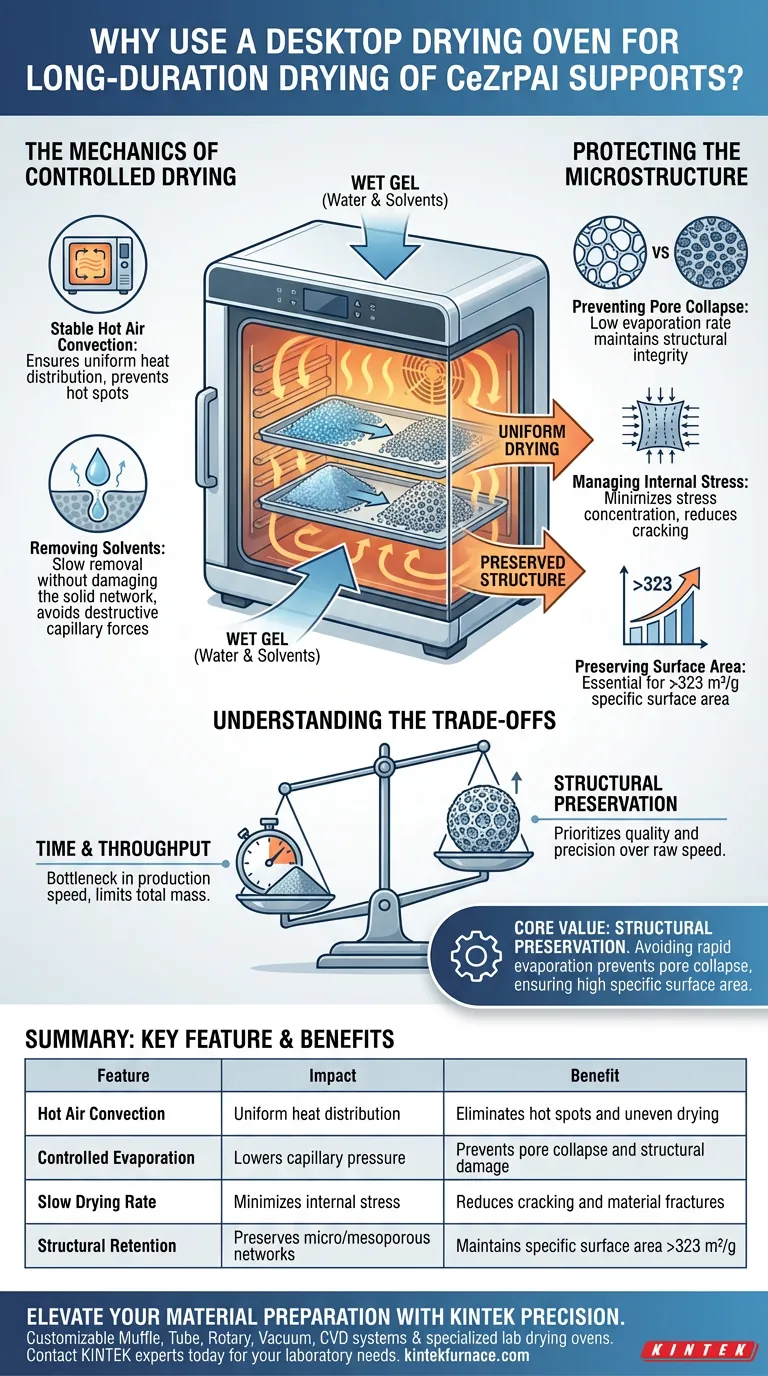

A desktop drying oven is utilized to create a stable, controlled hot air convection environment essential for processing CeZrPAl supports. This equipment ensures the slow and uniform removal of water and residual solvents from the wet gel generated during the sol-gel process. By strictly controlling the evaporation rate, the oven prevents internal stress concentrations that would otherwise destroy the material's delicate internal architecture.

The core value of this long-duration drying process is structural preservation. By avoiding rapid evaporation, the process prevents pore collapse, ensuring the final material retains the high specific surface area required for effective performance.

The Mechanics of Controlled Drying

Stable Hot Air Convection

The desktop drying oven provides a consistent thermal environment driven by hot air convection.

This stability is critical because it ensures that heat is distributed evenly across the material.

Uniform heat distribution prevents "hot spots" that could cause uneven drying rates within a single batch of wet gel.

Removing Solvents from Wet Gel

During the sol-gel process, the material exists as a wet gel saturated with water and solvents.

The drying phase must remove these liquids without damaging the solid network formed within the gel.

The oven facilitates this removal slowly, allowing solvents to escape from the gel network without generating destructive capillary forces.

Protecting the Microstructure

Preventing Pore Collapse

The primary risk during drying is pore collapse.

If liquid evaporates too quickly, the resulting capillary pressure can crush the delicate walls of the material's pores.

Long-duration drying in the oven mitigates this risk by keeping evaporation rates low enough to maintain structural integrity.

Managing Internal Stress

Rapid drying creates internal stress concentration within the material.

These stress points act as fracture sites, leading to cracks or a complete breakdown of the porous network.

The controlled environment of the oven ensures stress is minimized and distributed evenly, preserving the material's mechanical stability.

Preserving Surface Area

The ultimate goal of this careful drying is to maintain a high specific surface area.

The primary reference indicates that this process is essential for achieving a specific surface area of over 323 m²/g.

This high surface area is directly linked to the preservation of both microporous and mesoporous structures.

Understanding the Trade-offs

Time vs. Throughput

The most significant trade-off in this process is time efficiency.

"Long-duration" treatment creates a bottleneck in production speed, limiting how quickly supports can be manufactured.

However, attempting to accelerate this step creates an unacceptable risk of structural failure and reduced surface area.

Capacity Limitations

The use of a desktop unit implies a constraint on batch volume compared to larger industrial kilns.

While a desktop oven offers superior control for maintaining stability, it may limit the total mass of material that can be processed simultaneously.

This trade-off prioritizes quality and precision over raw mass-production speed.

Optimizing Your Preparation Process

To ensure the highest quality CeZrPAl supports, you must balance process efficiency with material integrity.

- If your primary focus is maximum surface area: Prioritize the stability of the convection environment and extend the drying duration to guarantee the metric exceeds 323 m²/g.

- If your primary focus is process speed: Recognize that this specific drying stage is non-negotiable; rushing it will result in pore collapse and a failed product.

Success in preparing CeZrPAl supports relies on accepting that slow, uniform drying is the only path to structural integrity.

Summary Table:

| Feature | Impact on CeZrPAl Supports | Benefit |

|---|---|---|

| Hot Air Convection | Uniform heat distribution | Eliminates hot spots and uneven drying |

| Controlled Evaporation | Lowers capillary pressure | Prevents pore collapse and structural damage |

| Slow Drying Rate | Minimizes internal stress | Reduces cracking and material fractures |

| Structural Retention | Preserves micro/mesoporous networks | Maintains specific surface area >323 m²/g |

Elevate Your Material Preparation with KINTEK Precision

Don't let pore collapse compromise your CeZrPAl research. KINTEK provides industry-leading drying solutions designed for high-precision applications. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems, alongside specialized lab drying ovens to ensure your materials achieve their maximum specific surface area.

Ready to optimize your drying process? Contact KINTEK experts today to find the perfect high-temp solution for your laboratory needs.

Visual Guide

References

- Feng Feng, Junchen Du. The Effect P Additive on the CeZrAl Support Properties and the Activity of the Pd Catalysts in Propane Oxidation. DOI: 10.3390/ma17051003

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What makes muffle furnaces versatile in their applications? Unlock Precision Heating for Diverse Industries

- What function does a Muffle Furnace serve in ZTO thin film post-treatment? Optimize Solar Cell Performance

- How does the performance of a high-temperature sintering furnace affect xPYNT–PINT ceramics? Key to Peak Properties

- Why is precise temperature control important in a muffle furnace? Ensure Reliable Results in Heat Treatment

- Why is it important to avoid exceeding the rated temperature of the muffle furnace? Prevent Damage and Ensure Safety

- How does a laboratory high-temperature box furnace influence the microstructure of H13 steel? Expert Insights

- Industrial Muffle Furnace Role in MgO Catalyst Preparation: Precision Thermal Engineering for Dry Reforming

- What are the benefits of muffle furnaces compared to tube furnaces? Choose the Right Furnace for Your Lab