In short, precise temperature control is the bedrock of reliable results from a muffle furnace. It ensures that a material is heated to the exact required temperature and held there with stability. This accuracy is essential for achieving consistent, repeatable outcomes in processes like heat treatment, ashing, and advanced materials research, where even small deviations can compromise the final product.

The question isn't just about hitting a target temperature; it's about controlling the entire thermal journey of a material. Precise control directly dictates a material's final structure and properties, making it the difference between a successful experiment and a failed one.

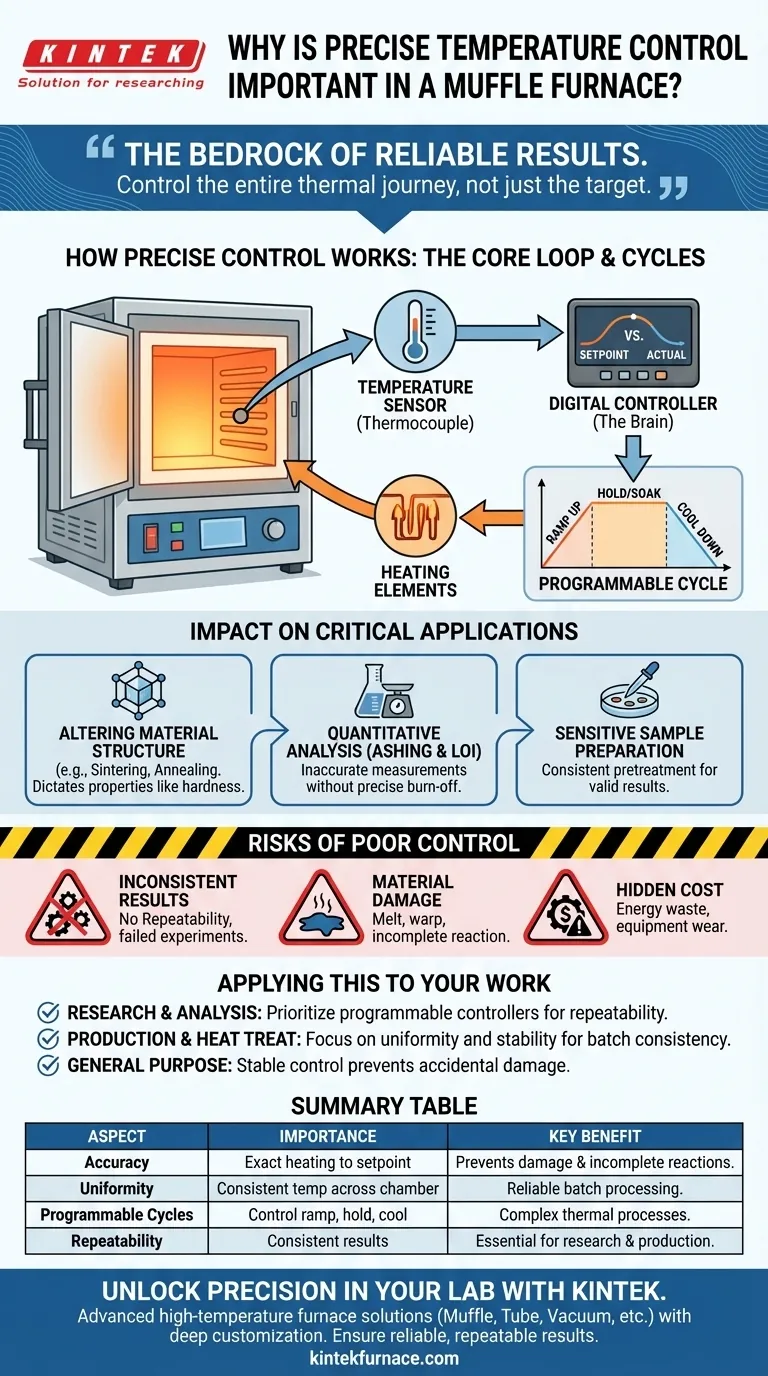

How Precise Temperature Control Works

Understanding the mechanism reveals why its precision is so vital. A muffle furnace doesn’t just turn on and get hot; it operates as a sophisticated feedback system.

The Core Control Loop

A temperature sensor, most often a thermocouple, is placed inside the heating chamber to constantly measure the internal temperature.

This sensor feeds live data to a digital controller. This controller acts as the brain of the operation.

The controller compares the actual temperature to the user-defined setpoint. If there's a difference, it adjusts the power sent to the heating elements to either raise or lower the temperature, creating a continuous loop of monitoring and adjustment.

Programmable Heating Cycles

Modern controllers offer more than just a single setpoint. They allow for programmable cycles that define the material's entire thermal process.

This includes the ramp rate (how quickly the temperature rises), the hold or soak time (how long it stays at a peak temperature), and the cooling rate. This level of control is crucial for complex processes.

Ensuring Temperature Uniformity

A primary goal of this control system is to achieve temperature uniformity. This means the temperature is consistent throughout the entire chamber, ensuring that a large sample or multiple small samples all experience the exact same thermal conditions.

The Impact on Critical Applications

Imprecise heating isn't just an inconvenience; it invalidates results and destroys materials across a range of scientific and industrial processes.

Altering Material Structure

For processes like sintering, annealing, and heat treatment, temperature directly manipulates the material's crystal structure and microstructure.

This, in turn, dictates final properties like hardness, strength, and conductivity. Without precise control, you cannot reliably engineer these properties.

Quantitative Analysis (Ashing & LOI)

In analytical chemistry, procedures like ashing or Loss on Ignition (LOI) are used to determine the composition of a sample by burning off its organic components.

The final weight is the result. If the temperature is too low, the reaction is incomplete. If it's too high, other components might degrade, leading to inaccurate measurements. Repeatability is impossible without precise temperature.

Sensitive Sample Preparation

In fields like drug testing and medical research, samples must be prepared under exact conditions to ensure the validity of the analysis.

Precise temperature control ensures that the pretreatment process is consistent and does not introduce variables that could skew sensitive test results.

Understanding the Risks of Poor Control

Failing to maintain precise control introduces significant risks that can waste time, money, and materials.

The Risk of Inconsistent Results

The most immediate risk is a lack of repeatability. If the furnace overshoots its target on one run and undershoots on the next, you will produce two different outcomes despite using the same settings. This makes reliable research or production impossible.

The Danger of Material Damage

Exceeding the target temperature can melt, warp, or otherwise destroy your sample. Conversely, failing to reach the required temperature can result in an incomplete chemical reaction or physical transformation, rendering the material useless for its intended purpose.

The Hidden Cost of Instability

A furnace with poor control often "hunts" for its setpoint, constantly overshooting and undershooting. This constant adjustment can lead to unnecessary energy consumption and place greater wear on the heating elements and control relays over time.

Applying This to Your Work

Your specific needs will determine how you prioritize furnace capabilities, but the principle of control remains universal.

- If your primary focus is research or quantitative analysis: Prioritize a furnace with a programmable digital controller to guarantee repeatability and documentable heating cycles.

- If your primary focus is materials production or heat treatment: Focus on specifications for temperature uniformity and the stability of hold times to ensure every part in a batch has consistent final properties.

- If your primary focus is general-purpose heating: Even for simpler tasks, stable temperature control prevents accidental sample damage and provides a reliable baseline for any process.

Ultimately, mastering temperature control means you are no longer just heating a material; you are precisely engineering its final outcome.

Summary Table:

| Aspect | Importance |

|---|---|

| Temperature Accuracy | Ensures exact heating to setpoint, preventing material damage and incomplete reactions. |

| Uniformity | Maintains consistent temperature across the chamber for reliable batch processing. |

| Programmable Cycles | Allows control of ramp rates, hold times, and cooling for complex thermal processes. |

| Repeatability | Guarantees consistent results across multiple experiments, essential for research and production. |

Unlock Precision in Your Lab with KINTEK

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Ensure reliable, repeatable results in heat treatment, ashing, and materials research—contact us today to discuss how our tailored solutions can enhance your processes and drive success!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength