Exceeding the rated temperature of a muffle furnace is a critical operational error that directly causes permanent damage to its most vital components. Pushing the furnace beyond its engineered limits drastically shortens its lifespan and compromises its performance by causing the heating elements and internal insulation to degrade and fail prematurely.

The maximum temperature rating on a muffle furnace is not a performance guideline; it is a fundamental engineering limit. Violating this limit sacrifices the long-term health, safety, and reliability of the equipment for a marginal, short-term temperature gain.

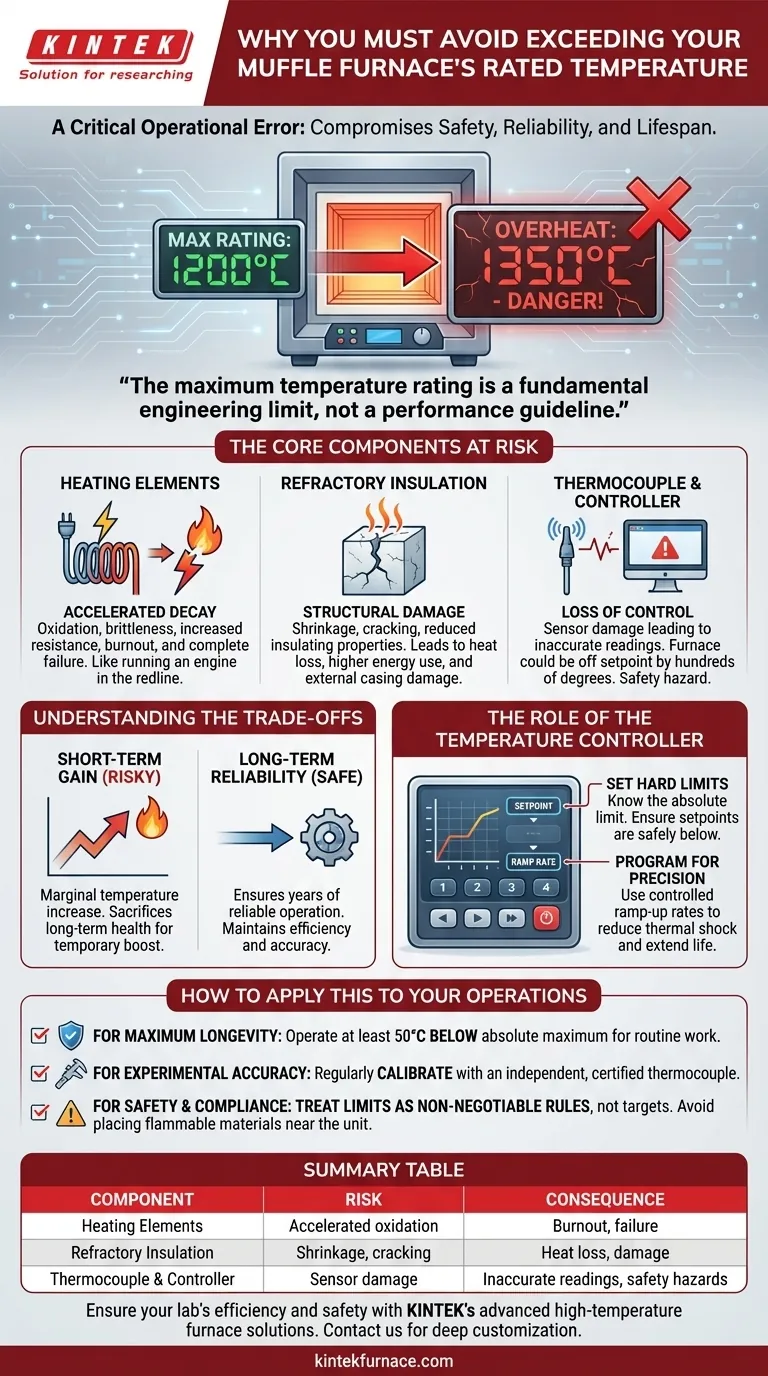

The Core Components at Risk

Operating a furnace above its maximum temperature initiates a process of accelerated decay. The damage is often irreversible and affects the very parts responsible for generating and containing heat.

The Heating Elements

The heating elements, typically made of alloys like Kanthal (FeCrAl) or materials like silicon carbide (SiC), are the heart of the furnace. These materials are chosen for their ability to withstand extreme heat, but they have a strict operational ceiling.

When this ceiling is exceeded, the elements oxidize and degrade at an exponential rate. This process makes them thinner, more brittle, and increases their electrical resistance, ultimately leading to burnout and complete failure.

The Refractory Insulation

The furnace chamber is lined with lightweight ceramic fiber or refractory bricks. This insulation is rated for a specific temperature.

Overheating causes this material to shrink, become brittle, and crack. This damage reduces its insulating properties, leading to significant heat loss, higher energy consumption, and potential heat damage to the furnace's external steel casing.

The Thermocouple and Controller

The thermocouple is the sensor that measures the internal temperature and reports it to the controller. While robust, an extreme over-temperature event can damage the thermocouple itself.

This leads to inaccurate temperature readings, causing a complete loss of process control. Your furnace might be hundreds of degrees off its setpoint without you knowing, ruining experimental results and creating a significant safety hazard.

Understanding the Trade-offs: Longevity vs. Temperature

The decision to respect temperature limits is a fundamental trade-off between achieving a slightly higher temperature now and ensuring the furnace operates reliably for years to come.

The Myth of "Just a Little More"

Even brief or minor excursions above the maximum rated temperature contribute to the cumulative damage. Each instance of overheating permanently reduces the lifespan of the heating elements, much like running an engine constantly in the redline.

Efficiency and Accuracy

A furnace with damaged insulation and aging elements is an inefficient one. It will consume more power to reach and maintain its setpoint temperature. Furthermore, if the thermocouple has been affected, any temperature readings become untrustworthy, rendering your work unreliable.

Operational Safety

Adhering to temperature limits is a core tenet of lab safety. A compromised furnace with cracked insulation or a damaged outer casing poses a burn risk. More importantly, disregarding manufacturer limits demonstrates a lack of operational discipline that can lead to other unsafe practices, such as placing flammable or explosive materials near the unit.

The Role of the Temperature Controller

Modern muffle furnaces use digital controllers to manage the heating process. This tool is your primary means of protecting the equipment.

Setting Hard Limits

The temperature controller allows you to set the desired temperature for your process. It is your responsibility to know the furnace's maximum rated temperature and to ensure that any setpoint is safely below that absolute limit.

Programming for Precision

Programmable controllers offer an even greater level of protection. By setting a controlled ramp-up rate (how fast the furnace heats up), you can reduce thermal shock on the elements and insulation, further extending their operational life.

How to Apply This to Your Operations

To ensure the longevity, accuracy, and safety of your muffle furnace, adhere to these key principles based on your primary goal.

- If your primary focus is maximum equipment longevity: Operate your furnace at least 50°C below its absolute maximum rated temperature for routine work.

- If your primary focus is experimental accuracy: Calibrate your furnace regularly with an independent, certified thermocouple to ensure your controller's readings are correct.

- If your primary focus is safety and compliance: Treat all manufacturer-specified temperature limits as non-negotiable rules, not as performance targets.

Proper temperature management is the single most important factor in maximizing the value and lifespan of your muffle furnace.

Summary Table:

| Component | Risk of Exceeding Temperature | Consequence |

|---|---|---|

| Heating Elements | Accelerated oxidation and degradation | Burnout, increased resistance, failure |

| Refractory Insulation | Shrinkage, brittleness, cracking | Heat loss, higher energy use, external damage |

| Thermocouple & Controller | Damage to sensor | Inaccurate readings, loss of control, safety hazards |

Ensure your lab's efficiency and safety with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today to protect your equipment and enhance performance!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide