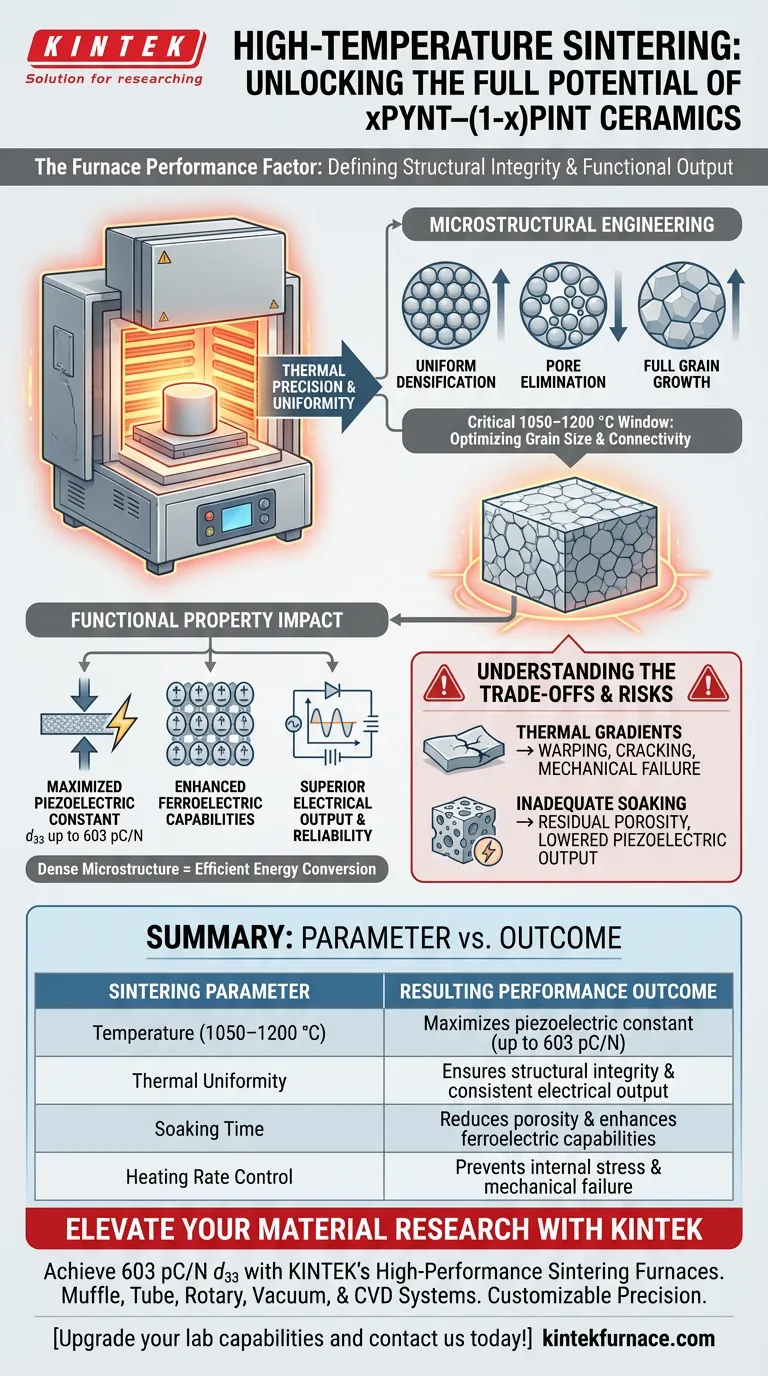

The performance of a high-temperature sintering furnace is the defining factor in establishing the structural integrity and functional output of xPYNT–(1-x)PINT ceramics. By maintaining a uniform thermal field and precise temperature control between 1050 °C and 1200 °C, the furnace facilitates the elimination of internal pores and promotes full grain growth. This densification process is directly responsible for maximizing the material's piezoelectric, ferroelectric, and electrical properties.

The furnace is not merely a heat source; it is a tool for microstructural engineering. Its ability to manage heating rates and holding times is the primary variable determining whether the ceramic achieves high density and a piezoelectric constant of up to 603 pC/N.

The Role of Thermal Precision in Microstructure

Achieving Uniform Densification

The primary function of the furnace during the final stage is to create a stable, uniform thermal field.

In xPYNT–(1-x)PINT ceramics, uneven heating leads to structural inconsistencies. A high-performance furnace ensures that thermal energy is distributed evenly, allowing the material to density uniformly throughout its volume.

Elimination of Porosity

Porosity is the enemy of performance in electro-ceramics.

Through accurate management of heating rates and soaking times, the furnace enables the material to expel nearly all internal pores. This results in a dense, solid ceramic body that is essential for high-end applications.

Facilitating Grain Growth

Temperature control directly dictates grain boundary movement.

Within the critical 1050 °C to 1200 °C window, the furnace allows grains to grow to their optimal size. This "full grain growth" is necessary to establish the connectivity required for robust electrical performance.

Impact on Functional Properties

Maximizing the Piezoelectric Constant

The direct result of proper sintering is a dramatic increase in the piezoelectric charge constant ($d_{33}$).

When the furnace successfully eliminates porosity and optimizes grain structure, xPYNT–(1-x)PINT ceramics can achieve a $d_{33}$ value of up to 603 pC/N. This metric represents the material's efficiency in converting mechanical stress into electrical charge.

Enhancing Ferroelectric Capabilities

A dense microstructure improves the alignment of electric dipoles.

By removing voids that interrupt the electric field, the furnace ensures the ceramic exhibits superior ferroelectric behavior. This translates to more reliable switching and polarization characteristics in the final device.

Understanding the Trade-offs

The Risk of Thermal Gradients

If the furnace fails to maintain a uniform thermal field, the ceramic will suffer from differential shrinkage.

This leads to warping or cracking during the cooling phase. Even if the piece survives, the internal stress distribution will degrade its mechanical strength and electrical consistency.

The Consequence of Inadequate Soaking

Cutting the "holding time" short to save energy or time is a common pitfall.

Insufficient soaking time prevents the material from reaching thermodynamic equilibrium. This leaves residual pores trapped inside the ceramic, which act as scattering centers for the electric field and significantly lower the piezoelectric output.

Making the Right Choice for Your Goal

To maximize the potential of xPYNT–(1-x)PINT ceramics, align your furnace operation with your specific performance targets.

- If your primary focus is Maximum Piezoelectric Output: Prioritize a furnace profile that holds the temperature strictly within the 1050–1200 °C range to push the $d_{33}$ constant toward 603 pC/N.

- If your primary focus is Structural Integrity: Ensure the furnace offers exceptional thermal uniformity to eliminate porosity and prevent internal stresses that lead to mechanical failure.

Ultimately, the quality of the sintering furnace sets the ceiling for the performance of the final ceramic component.

Summary Table:

| Sintering Parameter | Impact on xPYNT–(1-x)PINT Ceramics | Resulting Performance Outcome |

|---|---|---|

| Temperature (1050–1200 °C) | Facilitates full grain growth and pore elimination | Maximizes piezoelectric constant (up to 603 pC/N) |

| Thermal Uniformity | Prevents differential shrinkage and warping | Ensures structural integrity and consistent electrical output |

| Soaking Time | Allows material to reach thermodynamic equilibrium | Reduces porosity and enhances ferroelectric capabilities |

| Heating Rate Control | Manages microstructural engineering | Prevents internal stress and mechanical failure |

Elevate Your Material Research with KINTEK

Ready to achieve a piezoelectric constant of 603 pC/N? KINTEK’s high-performance sintering furnaces provide the thermal precision and uniformity required for the complex microstructural engineering of electro-ceramics.

Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique sintering requirements. Don't let thermal gradients limit your material's potential—ensure maximum densification and superior functional properties with KINTEK technology.

Upgrade your lab capabilities and contact us today!

Visual Guide

References

- Novel high-<i>T</i>C piezo-/ferroelectric ceramics based on a medium-entropy morphotropic phase boundary design strategy. DOI: 10.1063/5.0244768

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What functions do muffle furnaces serve in the petrochemical industry? Essential Catalyst Prep and Quality Control

- What environmental conditions are required for safe muffle furnace operation? Ensure Safety and Longevity in Your Lab

- What is a muffle furnace used for? Achieve Pure, High-Temperature Processing

- What is the primary function of a high-temperature box resistance furnace for γ-Y1.5Yb0.5Si2O7 ceramics? Optimal Sintering & Densification

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary purpose of using a high-temperature box resistance furnace during the pretreatment of kaolin catalysts? Optimize Performance & Structure

- What are common uses of muffle furnaces? Unlock Precision in Analysis and Material Processing

- How are box type resistance furnaces used in the manufacturing of electronic components? Essential for Precise Thermal Processing