For safe and reliable muffle furnace operation, the surrounding environment must be strictly controlled. The essential requirements are to maintain a relative humidity below 85% and ensure the air is completely free of conductive dust, explosive gases, and corrosive gases. These conditions are non-negotiable for preventing equipment failure and ensuring operator safety.

The environmental rules for a muffle furnace are not just a checklist; they are a system designed to mitigate three core risks: electrical short circuits, chemical degradation of the furnace, and catastrophic fire or explosion. A controlled environment is the foundation for both safety and repeatable results.

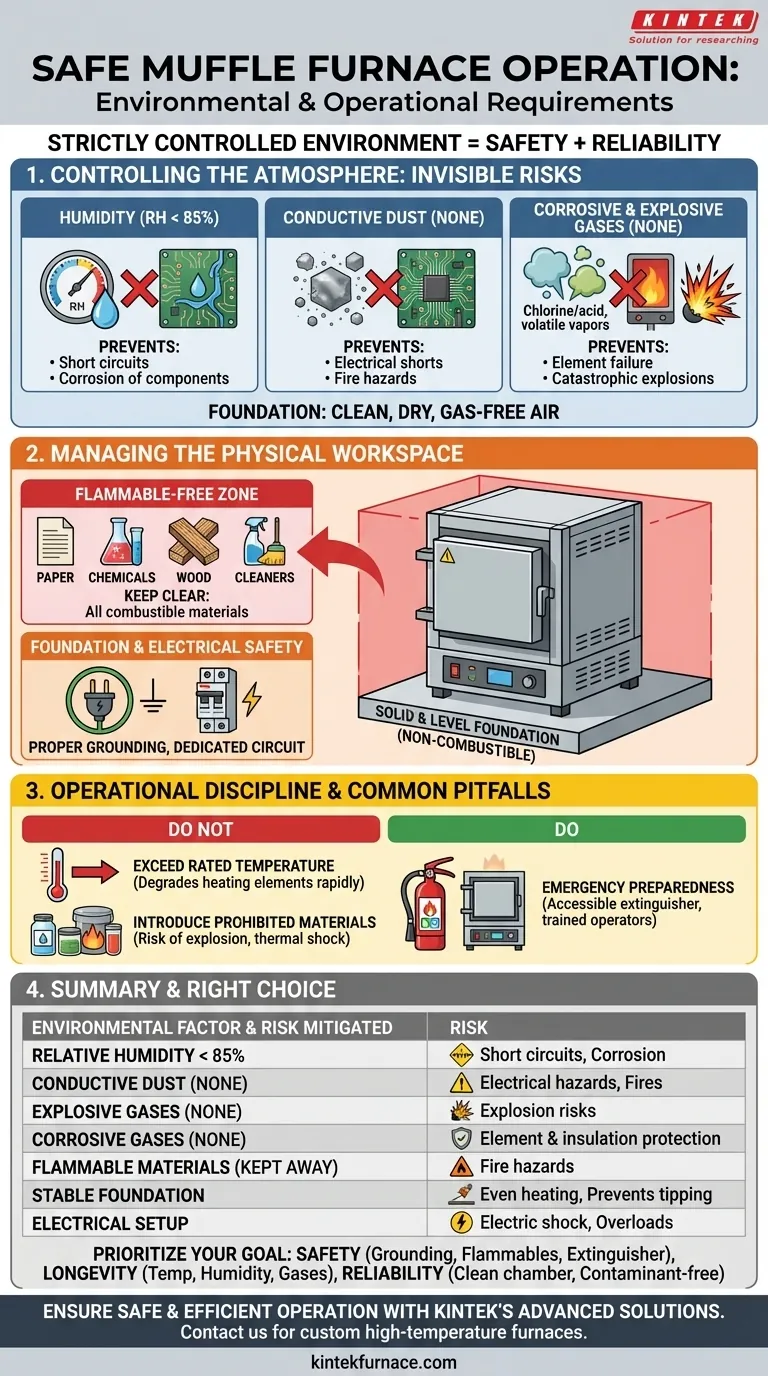

Controlling the Atmosphere: The Invisible Risks

The air in the room is the most critical environmental factor. What you cannot see—humidity, dust, and trace gases—poses the greatest threat to the furnace and its operator.

Why Humidity Matters (<85% RH)

High relative humidity introduces moisture into the environment. As the furnace heats and cools, this moisture can condense on sensitive electrical connections and insulation materials, creating pathways for short circuits. Over time, persistent humidity will also accelerate the corrosion of the furnace's metal casing and internal components.

The Danger of Conductive Dust

Dust from metal grinding, carbon, or other conductive materials is a significant electrical hazard. These fine particles can settle on circuits and inside control panels, bridging electrical gaps and causing short circuits that can lead to fire or irreparable damage to the control system.

Eliminating Corrosive & Explosive Gases

Corrosive gases, such as chlorine, sulfur compounds, or strong acids, will aggressively attack the furnace's heating elements and refractory insulation. This chemical attack dramatically shortens the equipment's lifespan and can lead to element failure during a run.

Explosive gases or vapors, from solvents or other volatile materials, create an extreme risk. A muffle furnace is a powerful ignition source, and any accumulation of flammable gas can result in a violent explosion.

Managing the Physical Workspace

Beyond the atmosphere, the physical setup of the furnace is a core component of its safe operation.

Establishing a Flammable-Free Zone

A muffle furnace radiates intense heat. All flammable and combustible materials—including paper, chemicals, wood, and cleaning supplies—must be kept far away from the unit. Never store anything on top of or immediately next to the furnace.

The Importance of a Stable Foundation

The furnace must be placed on a solid, level, and non-combustible surface. An unstable base can cause the unit to tip, creating a severe hazard. A level surface also ensures even heat distribution within the chamber.

Foundational Electrical Safety

The furnace must be properly grounded to prevent the risk of electric shock. It should be connected to a dedicated electrical circuit with a correctly rated breaker or fused disconnect to handle its high power draw without overloading.

Common Pitfalls and Operational Discipline

Operational errors are as dangerous as poor environmental conditions. Adhering to these principles is critical for maintaining a safe workspace.

The Consequence of Exceeding Rated Temperature

Never operate the furnace above its maximum rated temperature. Doing so causes rapid degradation of the heating elements, potentially destroying them in a single use. This is the fastest way to cause expensive and unnecessary damage.

Introducing Prohibited Materials

Do not place sealed containers or volatile substances in the furnace, as they can explode when heated. Furthermore, never pour liquids, molten metals, or wet samples directly into the furnace chamber, as this can cause thermal shock, cracking the insulation, and creating a mess that is difficult to clean and can contaminate future work.

Emergency Preparedness is Not Optional

A suitable fire extinguisher, typically a Class ABC or Class D depending on the materials being heated, must be located near the furnace. All operators must be trained on its use and be familiar with emergency shutdown procedures.

Making the Right Choice for Your Goal

To ensure a safe and effective setup, prioritize your actions based on your primary objective.

- If your primary focus is operator safety: Prioritize proper grounding, keeping the area clear of all flammables, and ensuring a fire extinguisher is immediately accessible.

- If your primary focus is equipment longevity: Emphasize never exceeding the rated temperature and ensuring the atmosphere is free of humidity and corrosive gases.

- If your primary focus is process reliability: Focus on maintaining a clean internal chamber and a workspace free from any dust or chemical contaminants that could affect your samples.

Ultimately, a disciplined approach to the operating environment is the single most important factor in achieving safe, repeatable, and successful results with your muffle furnace.

Summary Table:

| Environmental Factor | Requirement | Risk Mitigated |

|---|---|---|

| Relative Humidity | < 85% | Prevents short circuits and corrosion |

| Conductive Dust | None | Avoids electrical hazards and fires |

| Explosive Gases | None | Eliminates explosion risks |

| Corrosive Gases | None | Protects heating elements and insulation |

| Flammable Materials | Kept away | Reduces fire hazards |

| Stable Foundation | Solid, level surface | Ensures even heating and prevents tipping |

| Electrical Setup | Proper grounding, dedicated circuit | Prevents electric shock and overloads |

Ensure your muffle furnace operates safely and efficiently with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, enhancing safety, reliability, and performance. Contact us today to discuss how we can support your lab's goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity